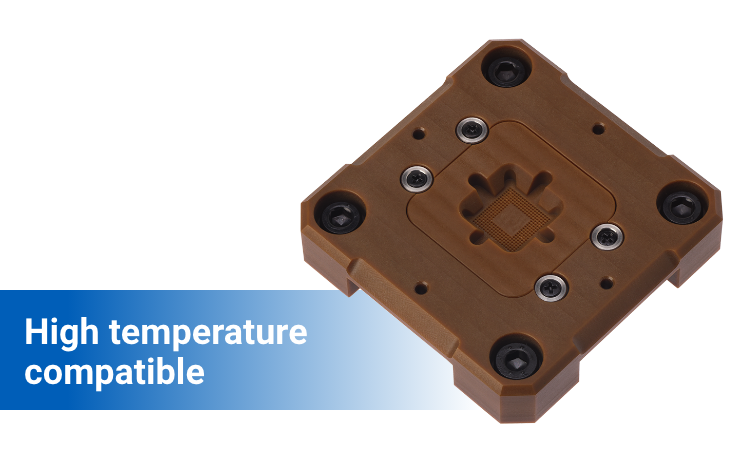

OMRON offers socket types that can be used in high temperature environments up to 200°C. The socket types can be used safely for a long period of time in burn-in tests, etc., where initial failures are eliminated in advance by applying temperature and voltage loads. Furthermore, with the same size design as pogo pins, it is possible to replace currently used pogo pins.

| Item | Specification |

|---|---|

| Contact force | 20gf at 1.0mm |

| Recommended stroke | 1.0mm |

| Maximum stroke | 1.4mm |

| Contact resistance | 100mΩ |

| Rated current | 1A |

| Ambient temperature | -40~200℃ |

| Plating | Au |

*Specifications are for reference only and may vary depending on the customized product.

We can custom design each pin and socket to suit the actual customer application. Please contact us for details.

Usable in high temperature environments up to 200°C

Usable in high temperature environments up to 200°C

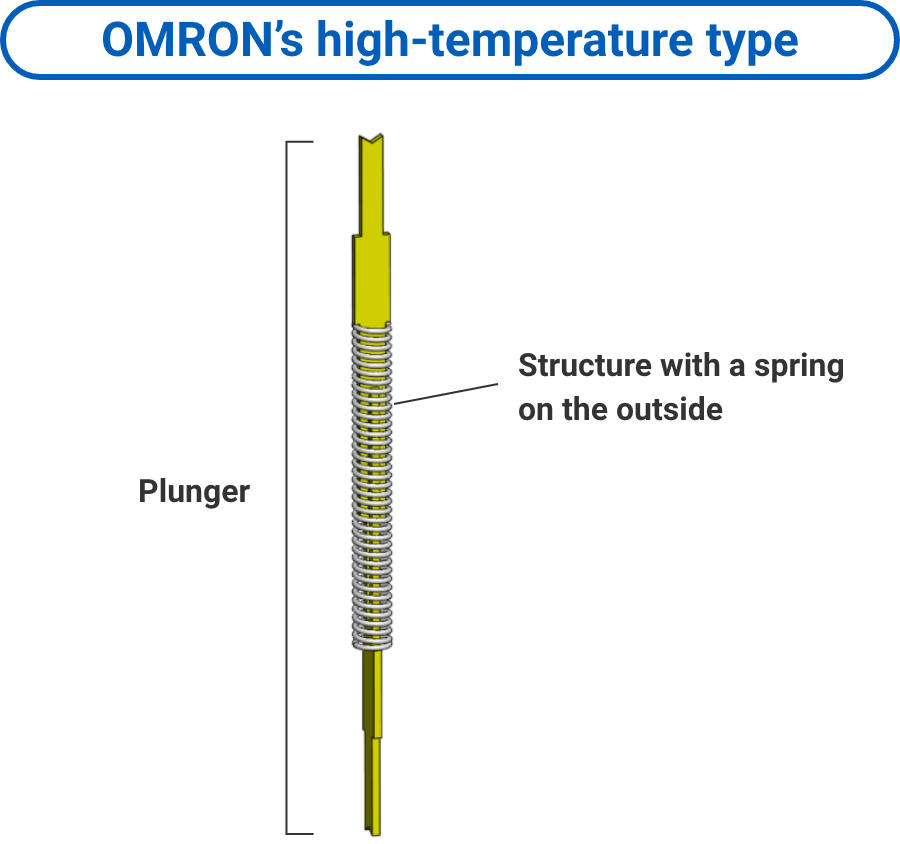

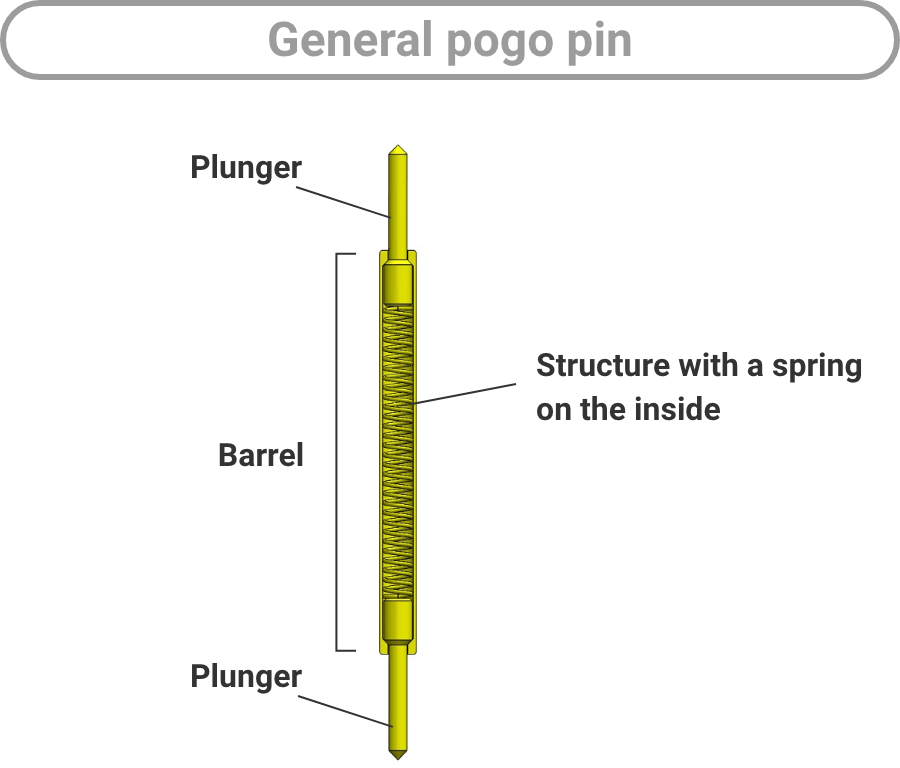

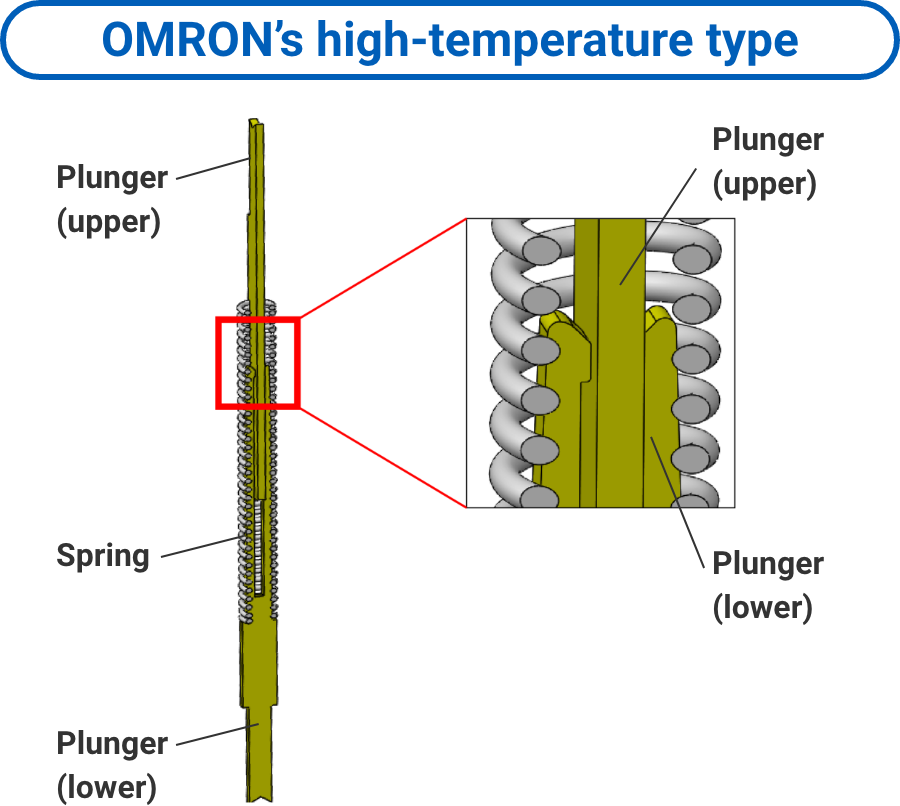

Pogo pins generally have a spring inside. Therefore, when used at high temperatures, depending on the combination of materials, the inner spring and outer housing may be welded together. However, OMRON’s high temperature compatible type testing pins have a structure that is resistant to welding by placing a spring made of heat-resistant material outside of the pin. The high temperature compatible type has a contact resistance of 100mΩ or less even after 500,000 operations at a high temperature of 180°C. Accurate inspections can be performed even in high temperature environments without being affected by contact resistance or mechanical life.

Safe inspection with stable contact

Safe inspection with stable contact

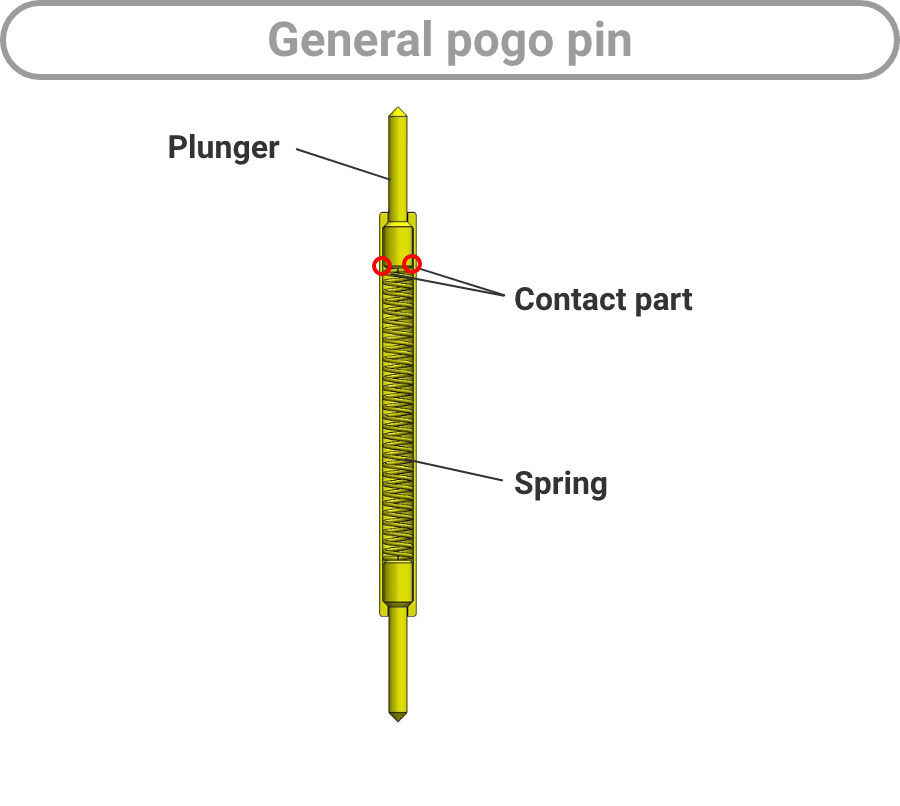

Pogo pins are basically composed of plunger, spring, and barrel designs, and conduction occurs when the plunger and spring come into contact with each other. Therefore, contactability is dependent on the movement of the spring. OMRON’s high temperature compatible type conducts electricity when the upper plunger and the lower plunger come into contact with each other. The contact structure is such that the lower plunger clamps the upper plunger from both sides, ensuring sufficient contact force. The stable contact ensures accurate inspections without being affected by variations in contact resistance.

The contact structure where the upper plunger sandwiches the lower plunger from both sides ensures stable contact.

The contact is unstable because it depends on the movement of the spring in a structure which conducts electricity when the spring and plunger come into contact with each other.

High durability and reduced maintenance

High durability and reduced maintenance

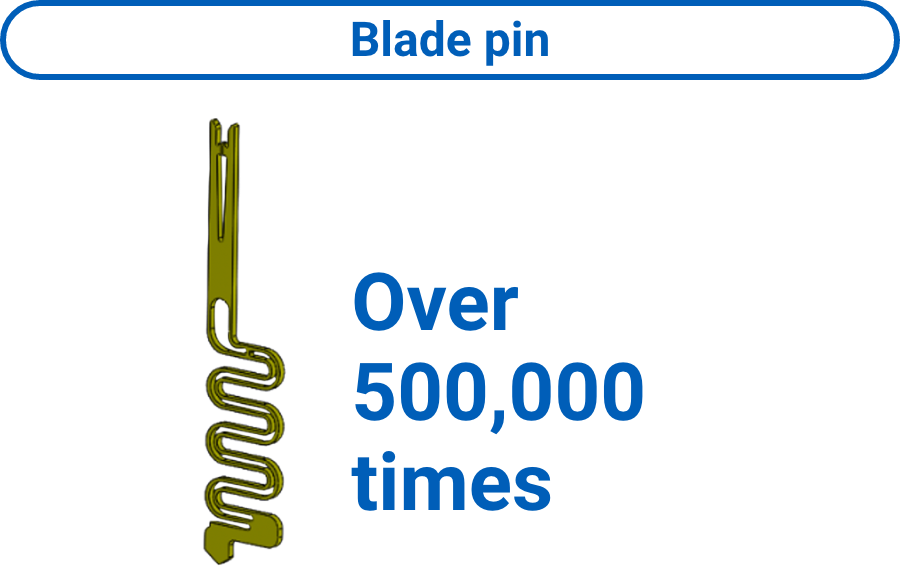

Custom design recommendations that best suit the customer’s application and OMRON’s original material blend* make our sockets more than five times more durable than pogo-pin sockets. This greatly reduces the frequency of testing socket replacement at the inspection site, contributing to improved production efficiency.

*Patent No. 5077479

*An example of B-to-B connector inspection