Traceability Management Technology

Management technology that handles quality control scientifically, based on quality data, and provides customers with products of stable quality while promptly responding to quality issues.

Features

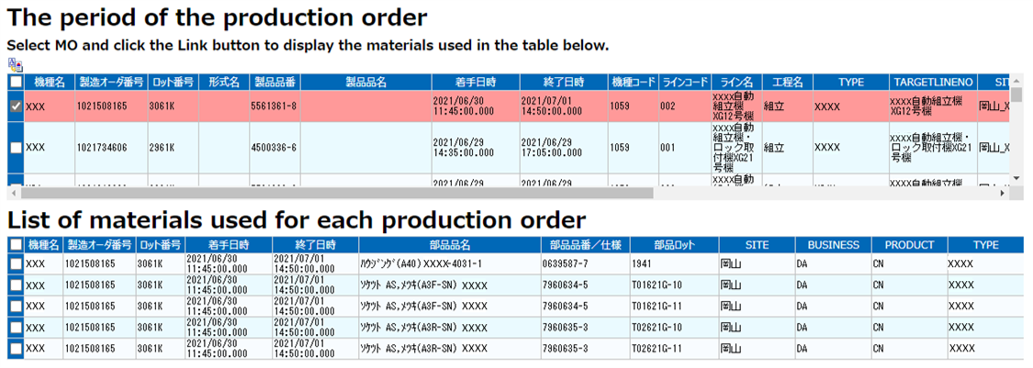

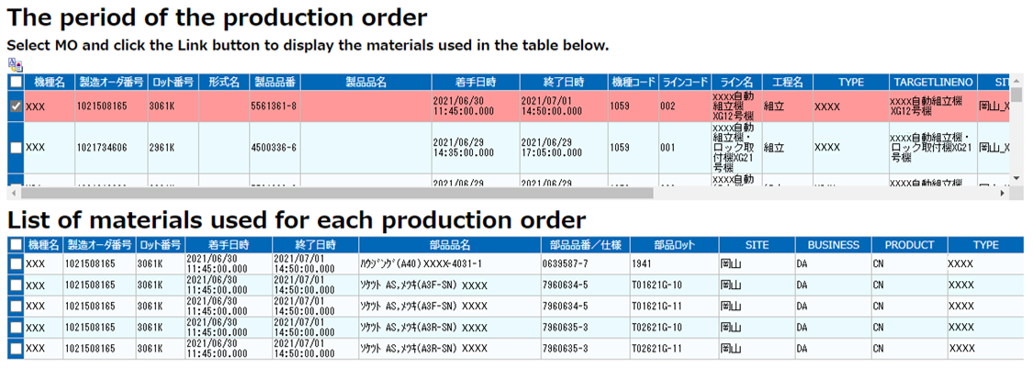

Speedy Lot Tracing

Centralized management of production history information speeds up the identification of causes and the narrowing down of targets when quality problems occur

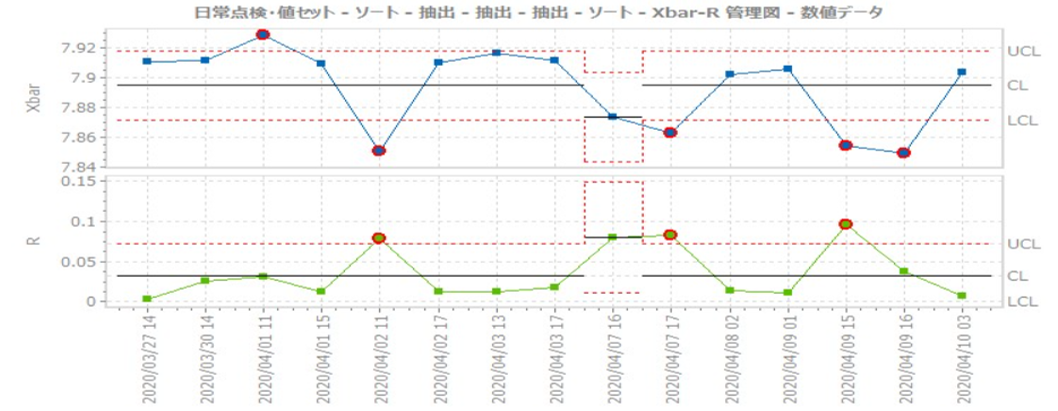

Sign Monitoring

Quality defects are prevented by monitoring signs of change from quality data accumulated on a daily basis

Global Quality Visualization

The quality status of production bases in remote areas is visualized

Application Examples

Speedy Lot Tracing

When quality fluctuations occur, the products/parts/scope affected and change history can be analyzed from the order number information, thus easily narrowing down the target range.

Sign Monitoring

A warning email will be sent automatically upon detection of abnormal trends. Correction results logs can also be checked to help prevent recurrence.

Quality Visualization

Quality can be improved by comparing quality information and 4M change information and identifying the 4M change points that cause quality fluctuations.