Built-In Color Sensor B5WC

- Proposal of Color Sensor Utilization

- Color sensor principle

- Product Specifications & Dimensions

- Related Contents

Summary

As labor shortages become more apparent, there is a growing need for automation through remote monitoring and more efficient maintenance in the manufacturing industry and multi-functional equipment in the service industry. Incorporating OMRON's "Color Sensors" into equipment can help solve these problems.

For example, in the case of machine tools, progressive deterioration of lubricant leads to equipment failure. It will become possible to efficiently maintain the equipment and gauge the optimal time to replace the lubricant by monitoring the color of the lubricant with a color sensor.

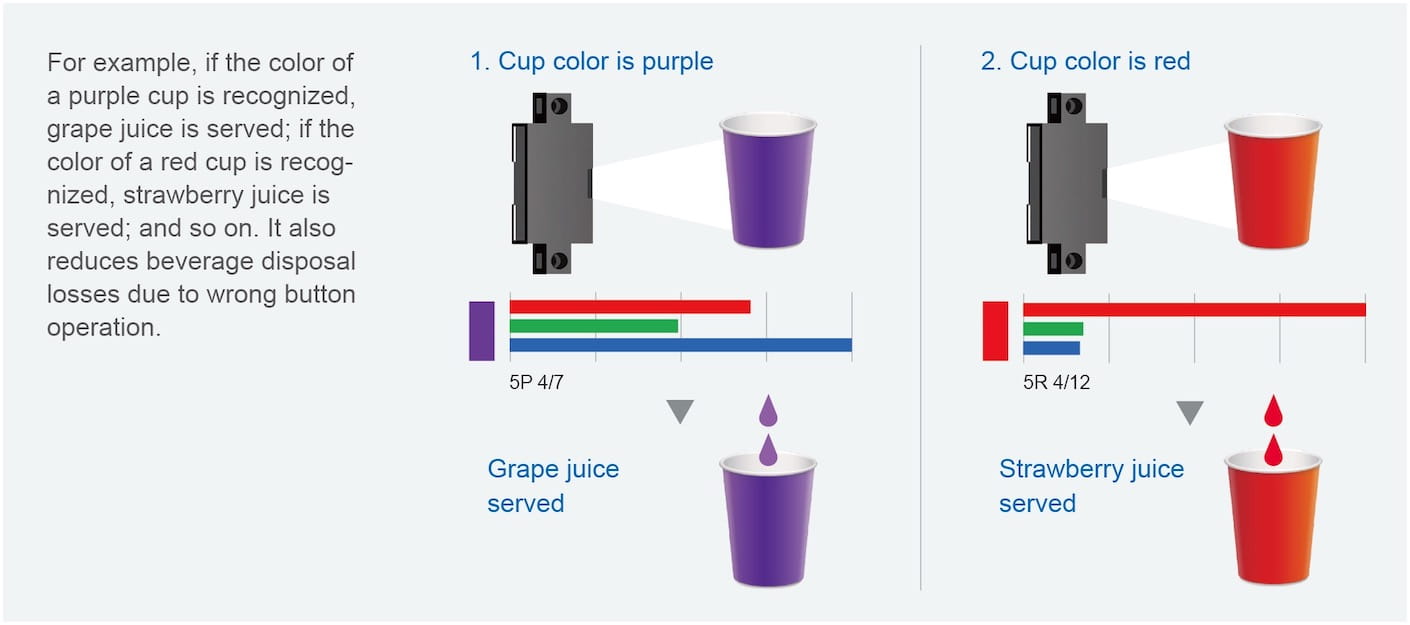

In the case of commercial drink dispensers, color sensors can automate beverage selection according to cup color, contributing to improved store work efficiency and reduced waste loss due to improper operation of buttons. For more information, please watch the video

Proposal of Color Sensor Utilization

1.Liquid condition monitoring

Challenge(1)

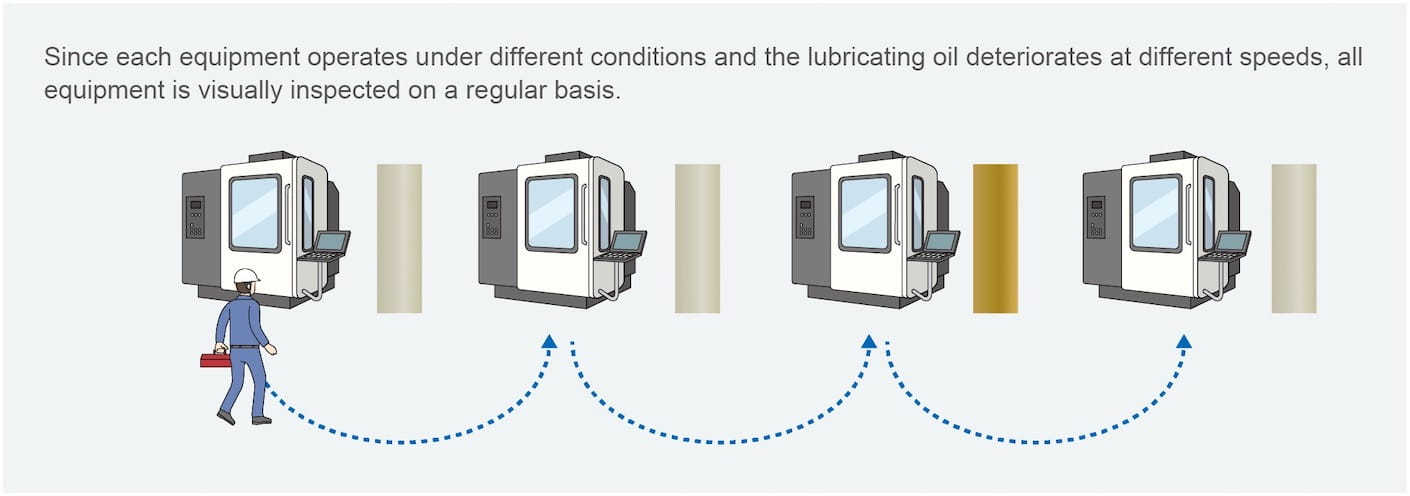

Deterioration of lubricating oil can cause equipment failure. If the timing of replacement is delayed due to the personal judgment criteria of each person in charge or the frequency of inspections, there is a risk of sudden breakdown or destruction of the equipment, which may result in loss of production for a certain period of time.

Solution(1)

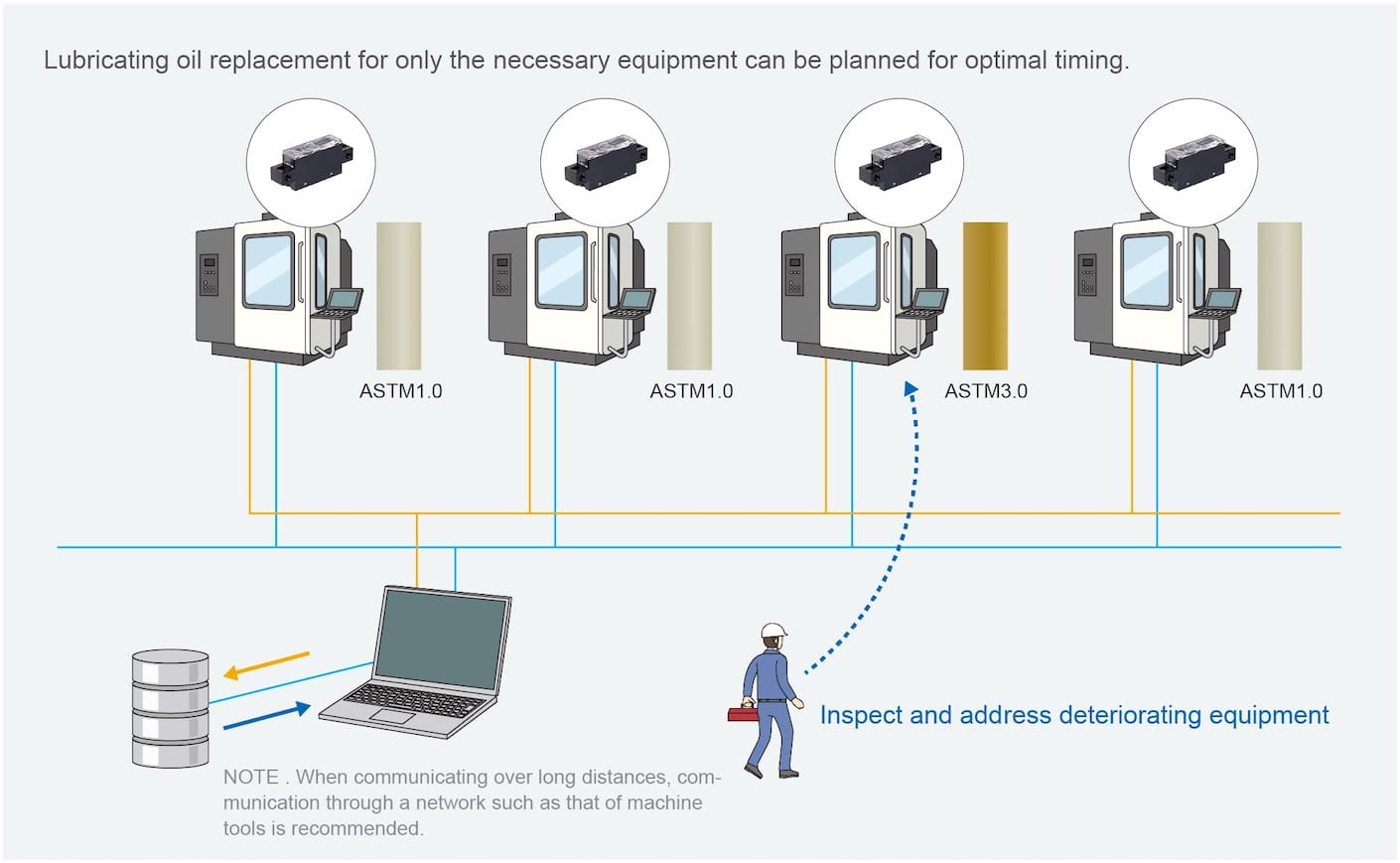

By monitoring the color of the lubricating oil with a color sensor, the deterioration of the oil for each equipment can be quantitatively monitored by color, and the oil can be replaced at the optimum time without depending on personal criteria.

The actual measurement of the lubricant with the color sensor can be seen in the video below.

Challenge(2)

Lubricating oil degradation differs for each equipment depending on operating conditions, making the oil replacement complicated and increasing man-hours required for management.

Solution(2)

Color sensors can be used for remote monitoring. The deterioration of lubricating oil in each equipment can be monitored by color, contributing to optimization of oil replacement timing and efficiency.

2.Multi-functionalization of equipment

Challenge

Presence/absence detection sensors can detect presence/absence, but cannot output signals according to type.

Solution

By color coding the equipment operation with signal output corresponding to the color of the color sensor, it is possible to build multi-functional equipment that meets diversifying needs.

The actual measurement of color with the color sensor can be seen in the video below.

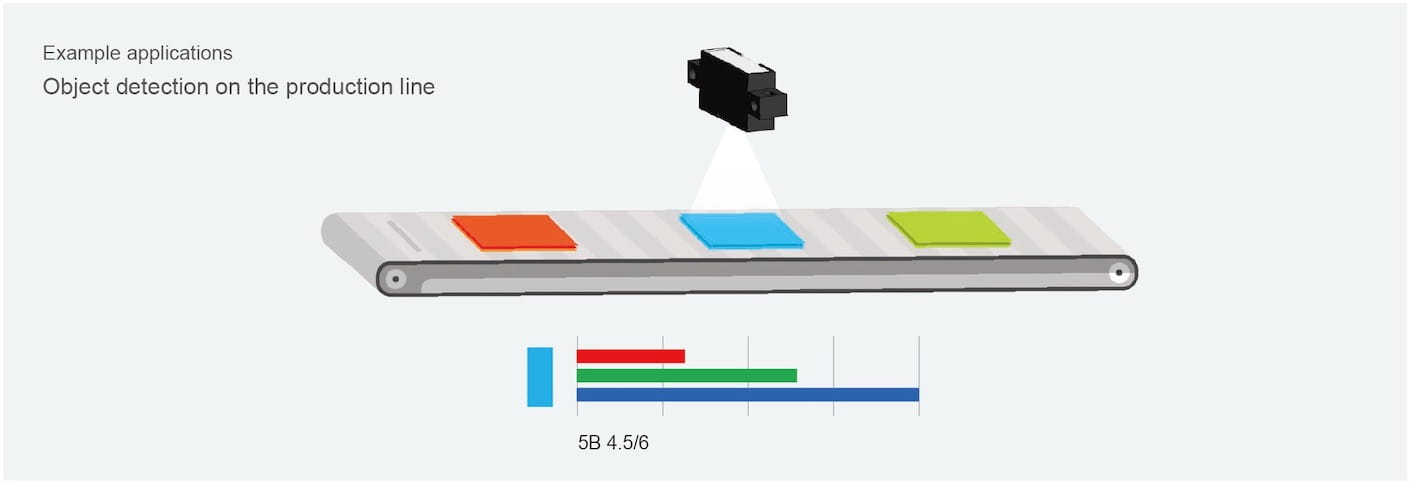

3.Stable operation of equipment

Challenge

In the case of conventional optical sensors, which detect the difference in the amount of reflected light, backgrounds may be detected or the object may not be stably detected due to the background.

Solution

The presence or absence of an object to detect may be confirmed by using a signal output from a color sensor for each color of the detected object.

The measurement with a general optical sensor and the color sensor can be seen in the video below.

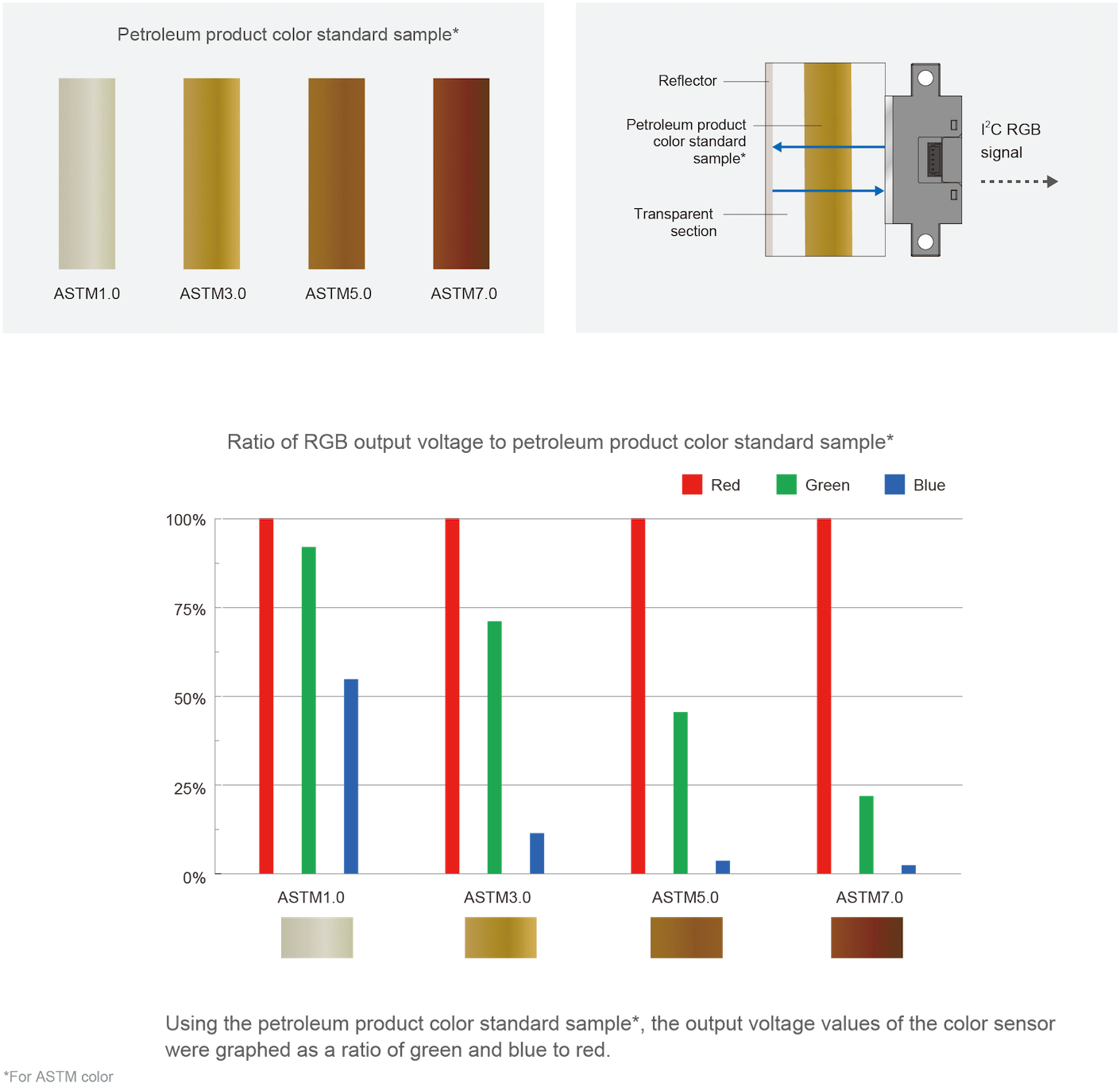

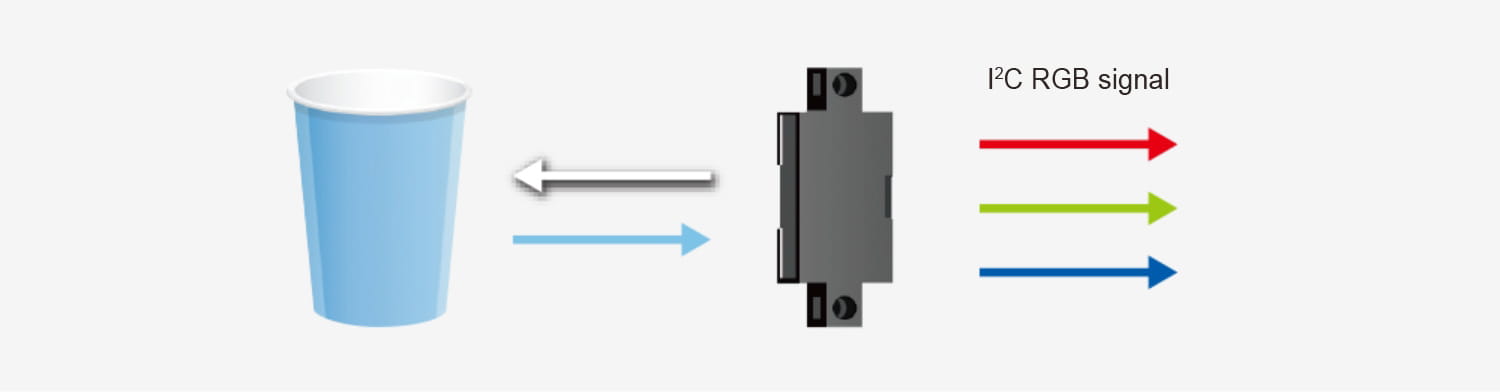

Color sensor principle

A color sensor uses a white LED as its light source to emit light and receive reflected light (the ratio of red, green, and blue is unique to each color) determined by the color of the detected object. The color sensor separates the reflected light received into red, green, and blue, and outputs the red, green, and blue data (RGB data) as voltage values using the I2C communication method.

For example, in the case of red and yellow detected objects, the red, green, and blue output values from the color sensor are different for red and yellow reflected light by the white LED, allowing differentiation of red and yellow.

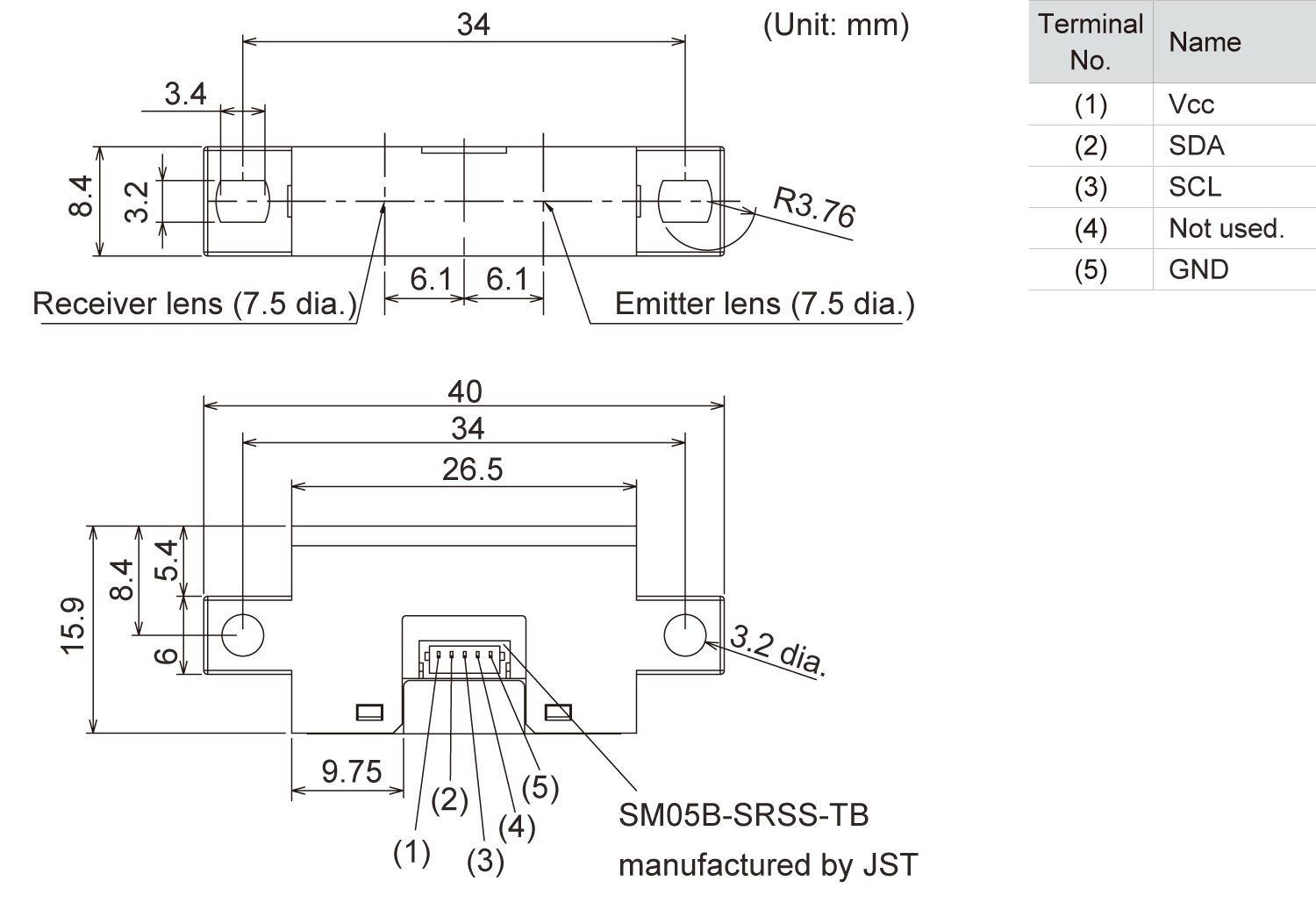

Product Specifications & Dimensions

Product Specifications

|

Item

|

Model

|

B5WC-VB2322-1 |

|---|---|---|

| Sensing distance | 40mm (white paper) | |

| Light source | White LED | |

| Power supply voltage | 5 VDC±5% | |

| Current consumption | 18 mA max. (at 5.25 VDC) | |

| Output type | I2C communications supported | |

| I2C output | Output voltage value for red/green/blue: 0.45 V±20% (gray reference plate, at sensing distance of 40 mm), Output saturation voltage: Typ 2.75 V (output voltage range: 0 to 2.75 V), SCL/SDA input H voltage: 2.54 to 5.4 V, Input L voltage: 0.9 V max., SDA output L voltage: 0.44 V max. (at output current of 3 mA) | |

| Sampling period | 1msec | |

| Data refresh period | Sampling period (1 msec) x Average count (1 to 50 times) | |

| Ambient temperature range | Operating: -10 to +70°C, Storage: -25 to +80°C (with no icing or condensation) | |

Dimensions