vol.277 February 2024

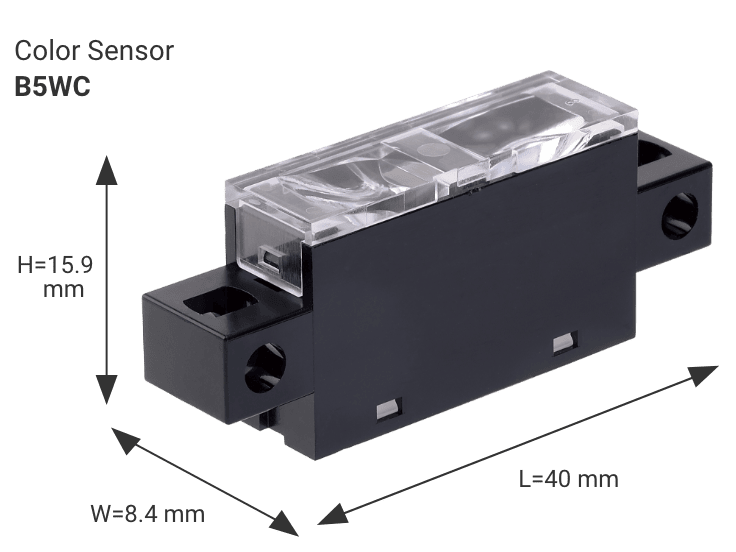

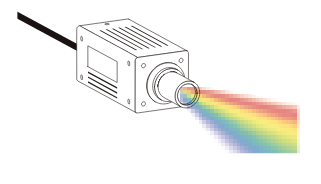

Color sensor for easy color detection

Development, implementation, and maintenance costs can be reduced.

|

|

|

|

|---|---|---|---|

|

Conventional camera  |

High development load Software development for image processing is required when converting colors, and software modification fees are also required when changing or adding colors. |

Over configuration An MPU with high processing power is required to process camera image data. |

Huge communication fees The amount of communication required to send image data to the host is enormous, and communication methods are limited. |

|

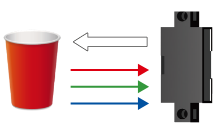

Color Sensor  |

Low development load No application development is required because the RGB voltage corresponding to the color is output from the sensor when converting colors. |

Optimal configuration Because the sensor handles RGB output voltages, processing by an inexpensive MPU is possible. |

Minor communication fees The sensor separates color into RGB and outputs only the RGB output voltage data, so color detection can be performed with a small amount of communication. |

This color sensor is small and can be easily integrated into equipment.

- Power-supply voltage: 5 V ±5%

- Digital output: A/D conversion not required on the product side

- Communication method: I2C

- Can be mounted from two directions with M3 screws

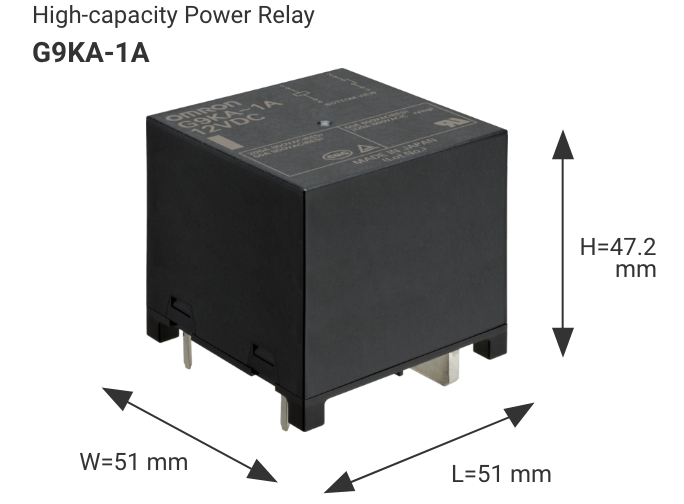

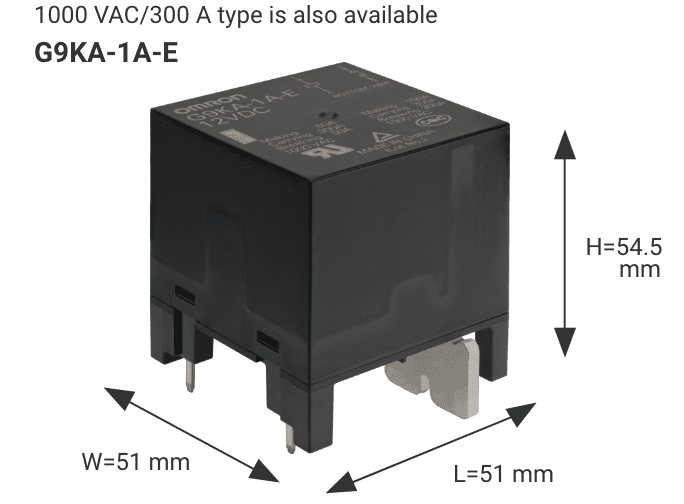

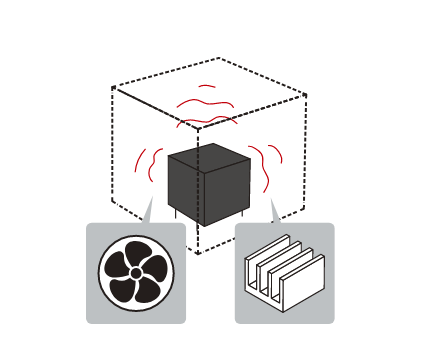

Low heat generation contributes to equipment miniaturization and high energy efficiency

Miniaturization of equipment by realizing low heat generation

800 VAC/260 A cutoff while reducing heat dissipating parts

General high-capacity power relay

Requires a fan and a heat sink

G9KA-1A

Low heat generation makes it possible to reduce the need for fans, heat sinks, etc., thus enabling equipment miniaturization

Realization of high energy efficiency

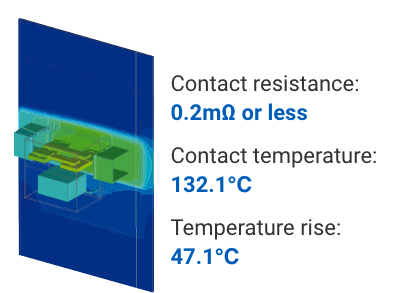

Industry-leading*1 ultra-low contact resistance (0.2 mΩ or less)

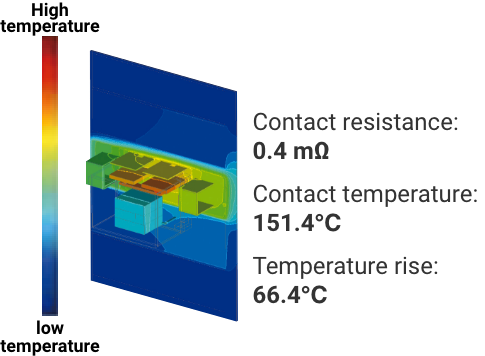

General high-capacity power relay

<Simulation conditions>

- 480 VAC / 200 A

- Ambient temperature 85°C

- Use of fans, ducts, and heat sinks

- One piece installed on a board

G9KA-1A

Improved energy efficiency by suppressing energy loss due to heat generation

*1. According to OMRON's research in July 2021.

* Contents as of January 2024.

In the interest of product improvement, specifications are subject to change without notice