Table of Contents

- What is Tactile Switch?

What makes you want to continue using it?

- Tactile switch vs. Membrane switch

- Recommended products by application

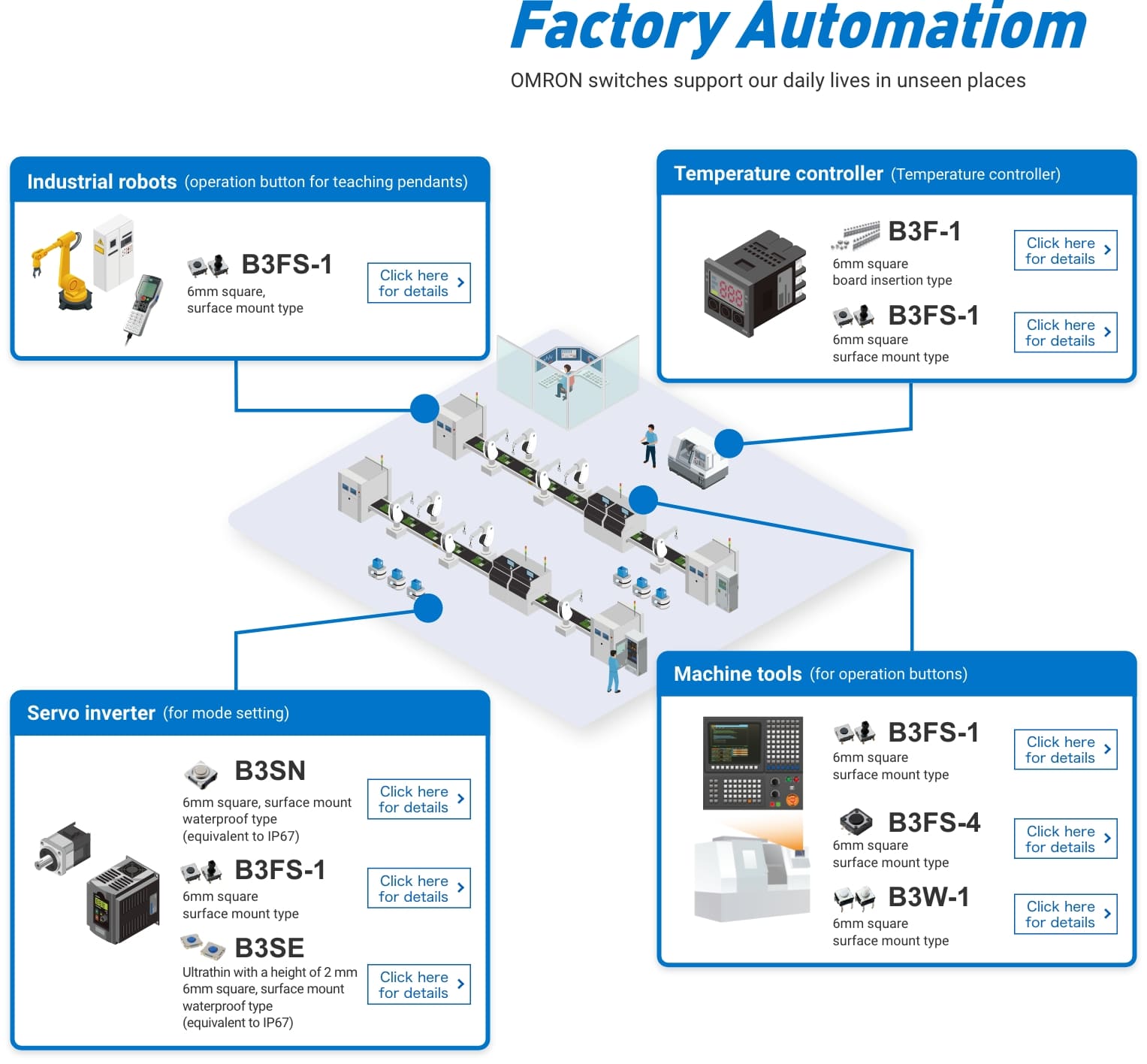

OMRON offers various types of mechanical switches for detecting, operating, and setting applications.

Among them, tactile switches, which are a type of operation switch, are used to start and stop facilities and equipment and to set and change operating conditions by human operation.

We are surrounded by various machines. When we operate these machines, we unconsciously perceive the reaction of a machine through the feel we get by operating it. When we press a switch used in home appliances, we can feel a "pop" or "click". We intuitively perceive whether an operation is being performed properly by the feel. On the other hand, if we cannot feel the operation, we cannot tell whether the operation has been completed properly, which leads to a sense of anxiety.

The operation feel can also contribute to the design of the product image. For example, a light operation feel allows for quick operation and gives a sense of speed, while a heavy operation feel gives a sense of luxury. In this way, the impression we get differs depending on the operation feel. Tactile is a word that expresses "a response that can be felt by touch" and is considered one of the important factors in the design of an operating switch.

There is a wide variety of OMRON's tactile switches to meet customers' needs in terms of external dimensions, operating environment, operation feel, and mounting method on printed circuit boards. They are used in a wide range of markets and industries, from business consumer equipment such as home appliances and office equipment to industrial equipment. In these fields, there are five features that make OMRON's tactile switches highly rated.

![[Example: Operation panel]Tactile switches placed on the board surface](/eu-en/sites/components.omron.com.eu/files/2023-03/tac_02_02_en.png)

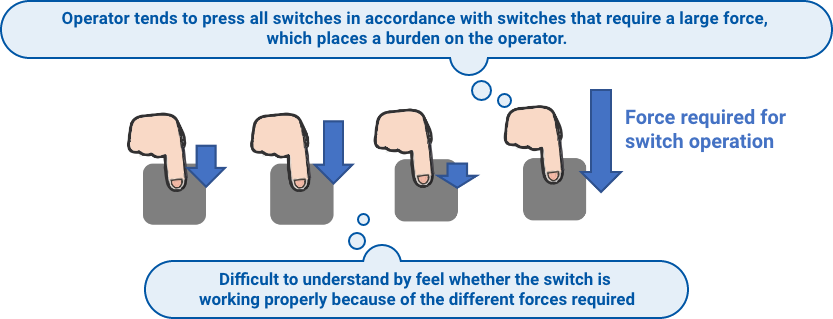

Tactile switches are placed side-by-side on the board surface of a device. Variations in the operation feel (load) of the various switches placed on the board surface make it difficult to judge by feel whether or not the button has been activated correctly, resulting in a decrease in work efficiency. In addition, variations in the operation feel of the switches for the same operation impose an excessively heavy burden on the operator, which can lead to increased “tiredness” and reduced “work comfort”.

What a person thinks when operating switches are placed side-by-side on the board surface

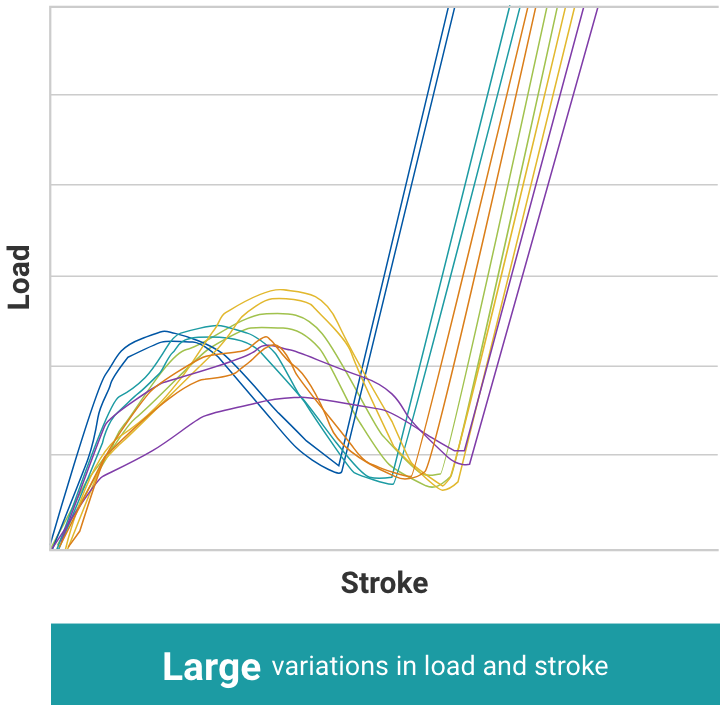

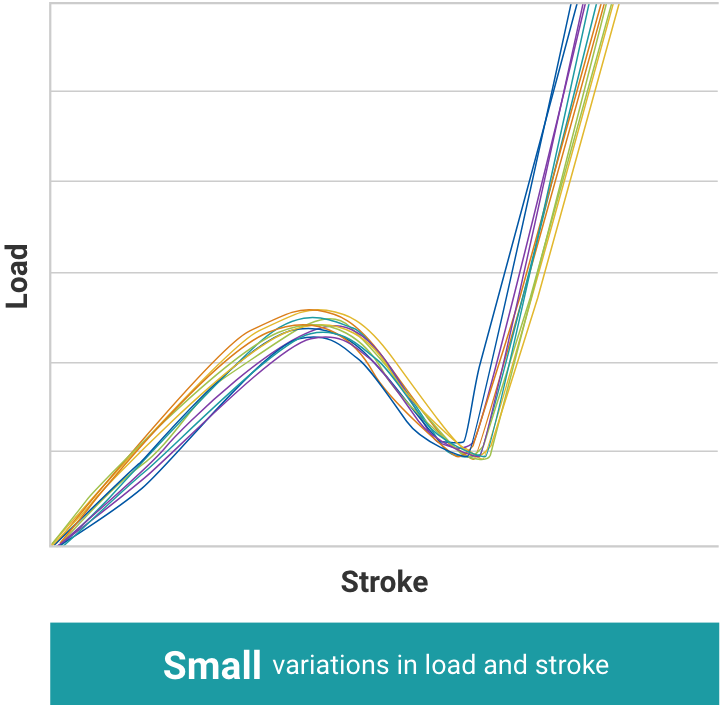

The operation feel is determined by two main factors: the load applied when the switch is pressed and the stroke. Because switches are composed of multiple parts, there will inevitably be slight variations in load and stroke between products due to the dimensional tolerances of the parts. There is less variation with OMRON's tactile switches compared to tactile switches with equivalent performance. Therefore, even in devices where many switches are placed on the same PCB, the switches have a uniform operation feel and can be used comfortably without sacrificing operability.

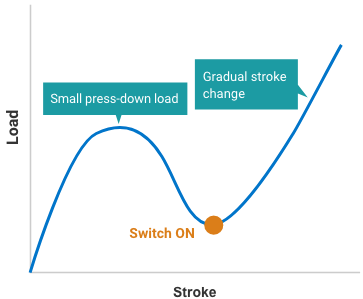

Load vs. Stroke characteristics

<Tactile switch with equivalent performance>

* For 12 mm, SMD type

<OMRON's tactile switch>

* For B3FS 12 mm, SMD type

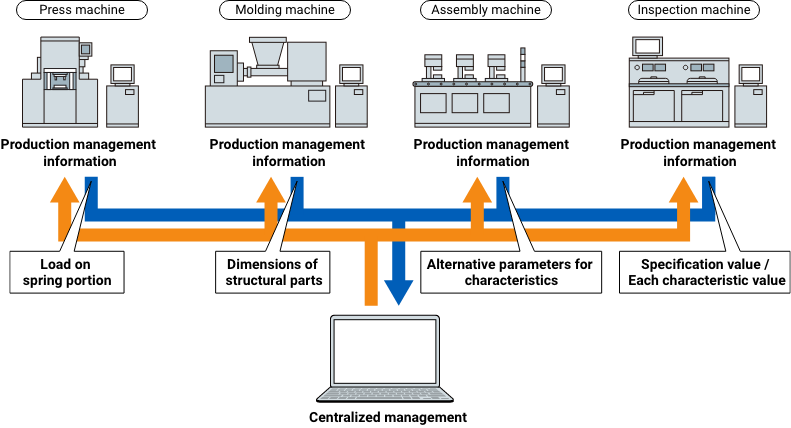

OMRON's commitment to minimizing variations in operation feel

OMRON's commitment to minimizing variations in operation feel

We have introduced an integrated production system from parts processing to product inspection. We have also introduced a characteristic inspection machine in the spring parts process, which determines the operation feel of the parts process, and measures the load on individual parts after they are produced. When there is a change of "0.01mm" from the center value specified by OMRON, the adjustment mechanism of the mold automatically performs feedback control and corrects the center value, which is a key point in achieving uniformity in the operation feel.

Tactile switches are usually placed on one side of equipment and used for information input operations, etc. However, because switches are pressed so frequently, it is labor-intensive, time-consuming, and costly to perform maintenance on many switches. "Hard to break" and "Usable for a long time" are essential for tactile switch applications.

In order to enhance the durability of switches various other elements are required, including knowledge about the selection of materials for the parts that make up the switch and a high level of technology to design the shape in addition to know-how on the mechanical mechanisms that open and close the contacts and the overall structure of the switch. OMRON is well versed in all the elements, based on years of experience in the switch business. OMRON's highly durable tactile switches help customers minimize maintenance.

OMRON's commitment to achieving a long operating life

OMRON's commitment to achieving a long operating life

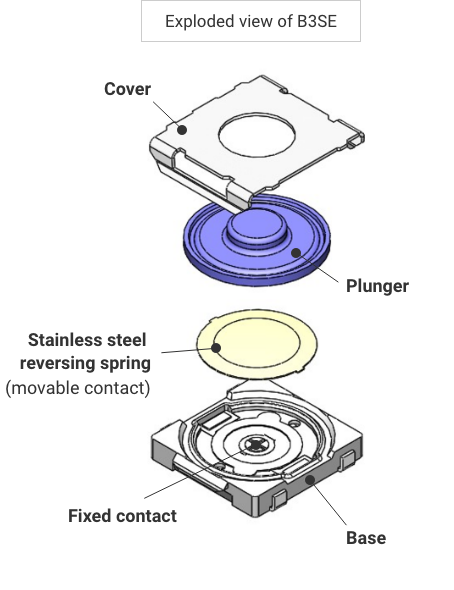

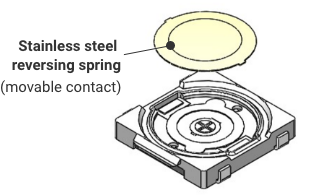

(1) High durability realized by a stainless steel reversing spring

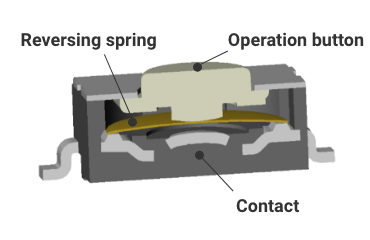

The reversing spring (movable contact) is a metal disc-shaped part. When force is applied, this spring reverses and the movable and fixed contacts come into contact, resulting in the ON state.

OMRON's general spring material is phosphor bronze, which has excellent spring properties, strength, and wear resistance. However, OMRON uses stainless steel for the reversing spring in its B3SE and B3FS-4. Compared to phosphor bronze, stainless steel has higher strength and hardness. Stainless steel spring can reduce wear on the contact points, thus providing superior mechanical durability and reducing maintenance man-hours.

(2) High heat resistance realized by a stainless steel reversing spring

In general, metals harden at low temperatures and soften at high temperatures. Therefore, under reflow soldering temperatures, in the case of a phosphor bronze spring, the spring dimensions change, and "settling" occurs, resulting in a weaker load. This makes it difficult to obtain the "operation feel" that is one of the values of a tactile switch. However, if the reversing spring is made of stainless steel material with high strength, the operation feel of the tactile switch will not become impaired because the spring will not settle easily and the load will not weaken. Even after reflowing, the operation feel is maintained for a long period of time, ensuring reliable long-term use.

Applicable models: B3SE, B3FS-4, B3SL, B3U, B3SN

Because tactile switches are used in various devices in a wide variety of environments, the switches may be required to have sealing performance.

The higher the sealing performance, the longer the product can be used without failure even in harsh environments. For tactile switches, which are usually placed in large numbers on the board surface of a device, the higher the sealing performance, the greater the reduction in maintenance frequency.

OMRON's commitment to high sealing performance with an upper/lower double sealed structure (Sealing performance equivalent to IP67 is ensured)

OMRON's commitment to high sealing performance with an upper/lower double sealed structure (Sealing performance equivalent to IP67 is ensured)

Depending on the equipment and application used, there are a wide range of needs for switches in terms of "comfort", "less fatigue", and "reliable operation feel". In addition to load and stroke, OMRON incorporates several parameters into its designs for optimum balance. OMRON has also built design capabilities and manufacturing processes that can reflect a comfortable operation feel suited to the equipment and application in products even in mass production.

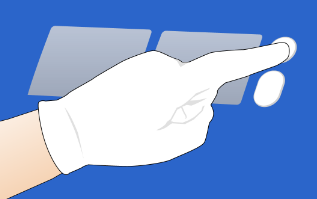

In some cases, depending on the work environment, the operator may have to perform the operation while wearing gloves. Operation wearing gloves makes the fingertip feeling duller than operation with bare hands, so an extraordinarily clear operation feel is required. OMRON has defined load and stroke patterns that provide reliable feedback that an operation has been made, and has reflected them in its tactile switches.

OMRON's commitment to realizing a comfortable operation feel

OMRON's commitment to realizing a comfortable operation feel

Sharp operation feel realized by a stainless steel reversing spring

The reversing spring (movable contact) is a disc-shaped metal part. When force is applied, this spring reverses and the movable and fixed contacts come into contact, resulting in the ON state. OMRON's general spring material is phosphor bronze, which has excellent spring properties, strength, and wear resistance. However, OMRON uses stainless steel for the reversing spring in some of its models. Compared to phosphor bronze, stainless steel has higher strength and hardness, which provides a sharper operation feel. Even indirect operation through gloves instead of bare hands conveys a clear operation feel.

| Comparison | Phosphor bronze reversing spring | Stainless steel reversing spring |

|---|---|---|

| Product |

B3F-4 |

B3FS-4 |

| Click sound |

|

|

| Operation feel |

(1) Falling load from the maximum load: The larger the load, the greater the operation feel.

Tests have proven that the stainless steel spring provides a clearer and crisper operation feel. |

|

OMRON's tactile switches are available in a total of 17 series with approximately 320 types*, allowing you to select the right product for your equipment. Consequently, we have a lineup of products with rare specifications that are not often handled by other companies. You do not have to worry about compromising the design of your equipment by having multiple manufacturers' tactile switches on the board due to the lack of tactile switches you want.

*As of December 2022

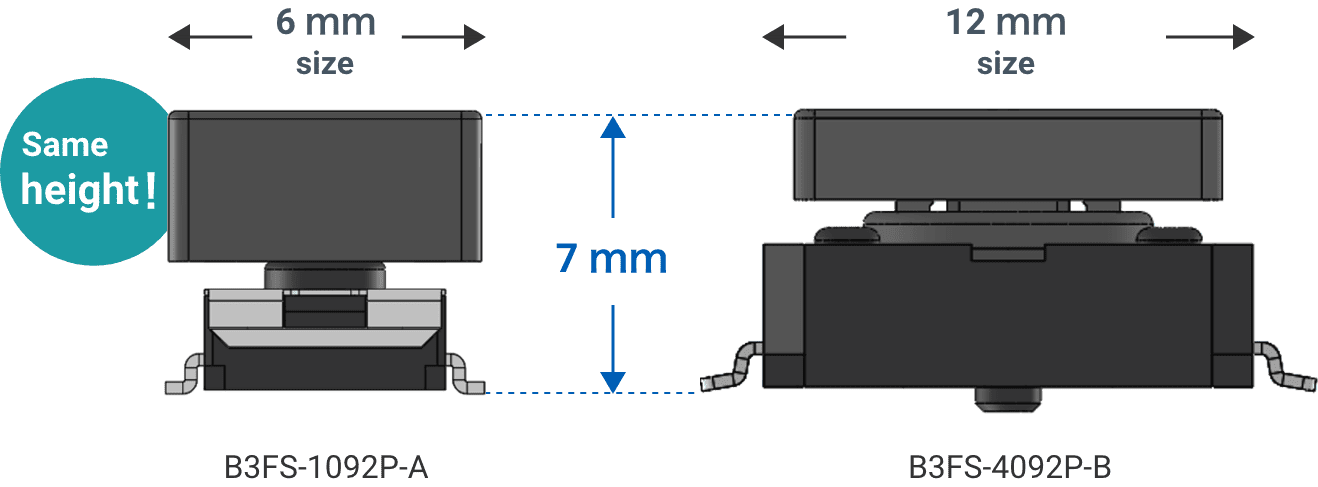

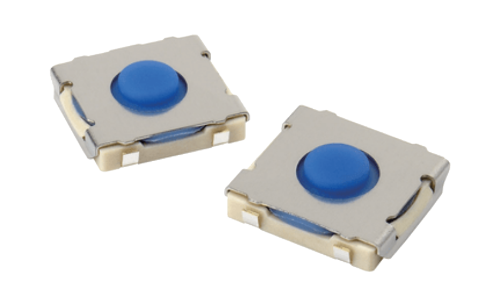

B3FS-4/B3FS-1 Keytop-integrated type

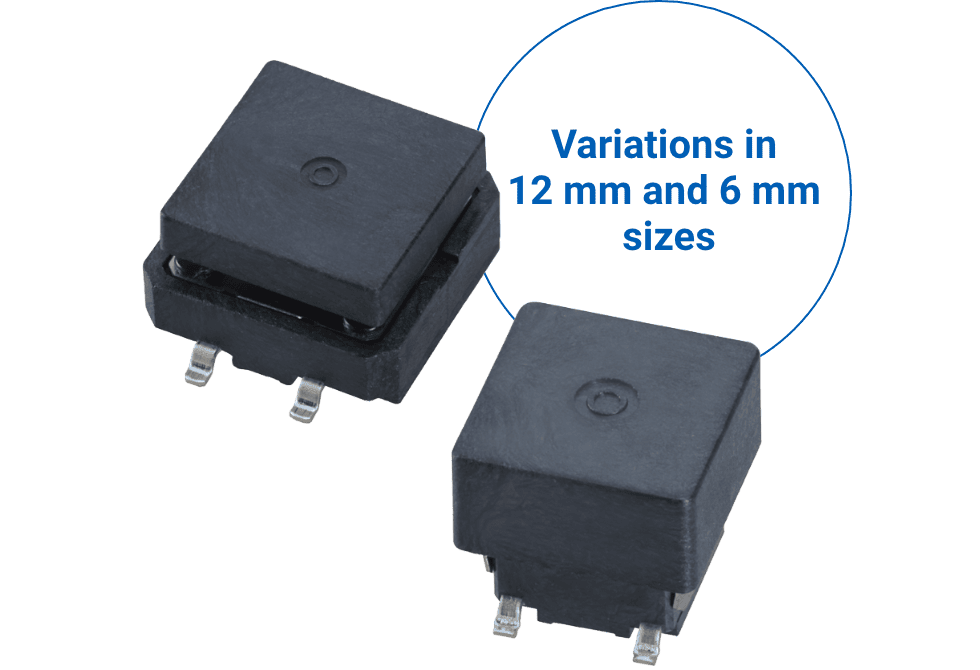

There are probably many cases where dozens of tactile switches are arranged on a board surface, especially in factory automation equipment. The challenge, then, is the man-hours required to incorporate tactile switches during manufacturing and maintenance. Tactile switches can be automatically mounted on a board using reflow solder, but key tops must be installed manually. However, the use of keytop-integrated tactile switches can cut the man-hours required for manual operations, thus greatly increasing work efficiency. In addition to the standard 6mm size, a 12 mm size variation that is useful for factory automation equipment is available. Select the most suitable tactile switch for your application.

12 mm size (B3FS-4)

6 mm size (B3FS-1)

Awesome features!

Awesome features!

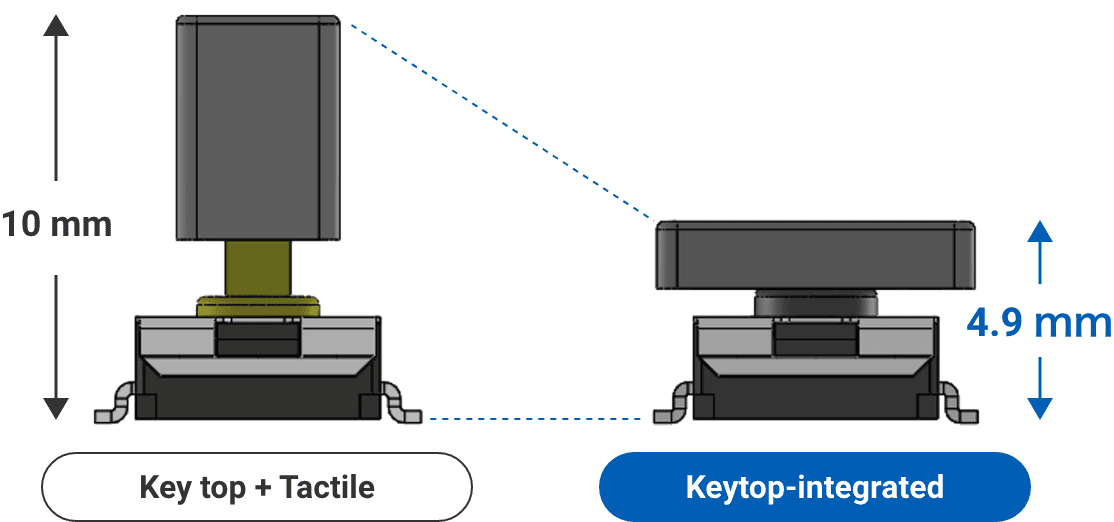

By combining our long-accumulated technological, production, and quality assurance capabilities, we have achieved a lower profile than conventional products with key tops installed, despite the keytop-integrated type. This makes automatic mounting using reflow soldering and tactile switch operation more stable and comfortable than with conventional products. In addition, its compact size contributes to making equipment thinner and smaller.

For 6 mm size (B3FS-1)

* For B3FS-1092P/1095P

For 12 mm size (B3FS-4)

* For B3FS-4092P-B

Awesome features!

Awesome features!

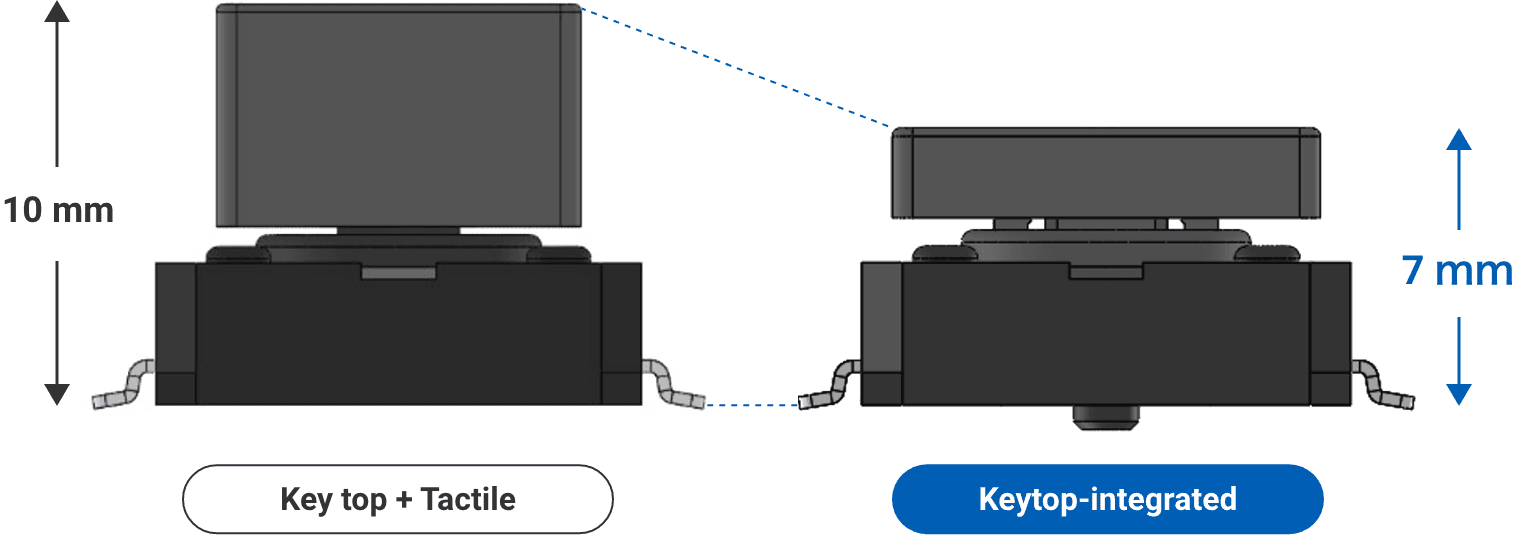

Same height for both 6mm and 12mm sizes.

Uniform operation position can be achieved by mounting on the same board!

We also have a lineup of 6mm size tactile switches with integrated key tops, which are the same height as the 12mm size. By arranging tactile switches of different sizes on the same board in a unified manner, comfortable operation and a clean design design can be achieved.

B3SE plunger type

Dimensions: 6.2 x 7.2 mm

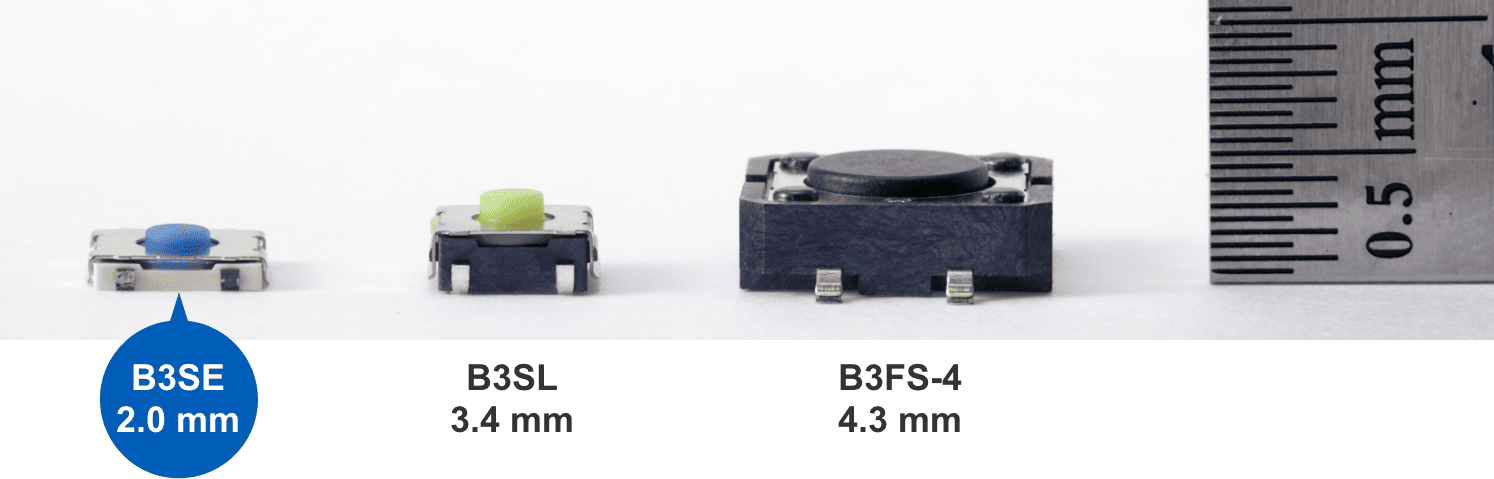

Equipment is becoming smaller and thinner at an accelerating pace in every industry. In the elevator market, there is a shift from conventional recessed control panels to panel-type control panels that can be wall-mounted for ease of maintenance. In our daily lives, "small and long-lasting" has become the norm for home appliances and beauty equipment. In addition to realizing waterproof and dustproof performance equivalent to IP67 and a long operating life of one million cycles of mechanical durability, OMRON's B3SE has realized an industry-leading* thin-profile structure. The B3SE is an ultrathin type with a thickness of only 2 mm. How about OMRON's compact, high-performance B3SE for every occasion?

*As of December 2022

Thickness comparison of OMRON tactile switches

B3SN gold plated type

Tactile switches are used in various environments, depending on the equipment in which they are mounted. For example, silver-plated tactile switches may cause equipment corrosion when used in hot spring areas containing sulfur or in manufacturing sites where various gases are generated. Gold-plated tactile switches can be used for a long time because they can reduce contact failures caused by corrosion.

B3FS-4 external size 12mm type

While small and easy to place 6mm size tactile switches have become the mainstream for home appliances, large and easy-to-press 12mm size tactile switches are required for large machines such as control equipment. OMRON has a lineup of 12mm size surface-mount type tactile switches, which is rare among Japanese manufacturers.

Compatible with small-lot reels

The minimum order unit for compact, inexpensive tactile switches is generally a 3000-piece reel product. However, OMRON handles the smallest lot of a 100-piece reel as a quantity that is easily accessible to customers. Switches will naturally deteriorate if they are purchased and left unused. OMRON's tactile switches can be purchased in quantities that can be used up, which helps reduce disposal volume, disposal costs, and procurement costs. Furthermore, there is no need to occupy inventory space for an extended period of time.Being a reel product, it can be set directly in the mounting machine and can be used immediately.

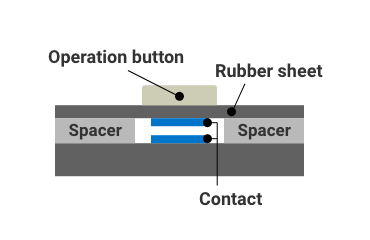

Membrane switches are used in similar applications to tactile switches. They are thin-profile switches consisting of multiple layers of PET film, with conductive circuit patterns formed by silk-screen printing. Compared to membrane switches used for the same application, tactile switches are well suited for use in production. Clear operation feel and sound clearly inform the operator whether the switch is working properly even when he or she is wearing gloves. Membrane switches have contacts made of conductive paste, so they have a short mechanical life due to contact wear or rubber deterioration, whereas tactile switches have high durability due to less contact wear and mechanism deterioration caused by operation. The use of tactile switches will help improve your work efficiency and reduce maintenance man-hours.

| Name | Tactile switch | Membrane switch |

|---|---|---|

| Structure |  |

|

| Feel |

Clear operation feel

This switch can only be pressed in with a large load applied, thus preventing erroneous input. The rapid change in load and stroke gives a solid clicking feel. |

Soft operation feel

The gradual change in load and stroke gives a soft clicking feel. |

| Operation sound | Sharp spring reversal sound such as "click, click" | Sharp spring reversal sound such as "click, click" |

| Durability | Higher durability than membrane switches | Low durability due to contact wear and rubber deterioration |

| Replaceability | Only broken switches can be replaced individually. | Buttons are arranged in a sheet. The entire sheet needs to be replaced because broken switches cannot be replaced individually.

|

How did you like OMRON's tactile switches?

Please take advantage of OMRON's high quality tactile switches in various situations and for various applications.

![Smart Home OMRON switches support our daily lives in unseen places Bathroom (for bathroom control panel) B3S:6mm square, surface mount waterproof type (equivalent to IP67) B3W-1:6mm square, board insertion waterproof type (equivalent to IP67)B3WN:8mm square, board insertion waterproof type (equivalent to IP67) Restroom (washlet / control button) B3S:6mm square, surface mount waterproof type (equivalent to IP67) B3W-1:6mm square, board insertion waterproof type (equivalent to IP67)Security equipment (Operation button for reset [gold-plated]) B3SN:6mm square, surface mount waterproof type (equivalent to IP67)B3U:Subminiature(H1.2 x L3.0 x W2.5 mm) Surface mount type for high-density mounting Air purifier (mode setting operation button)B3W-1:6mm square, board insertion waterproof type (equivalent to IP67) B3SL:6mm square, middle stroke surface mount waterproof type (equivalent to IP67)](/eu-en/sites/components.omron.com.eu/files/2023-03/tac_08_02_en.jpg)