What causes abnormal sounds when a relay is in use?

ID: FAQE10092E

update:

Answer

Possible causes differ for AC relays and DC relays. Refer to Explanation for details.

Explanation

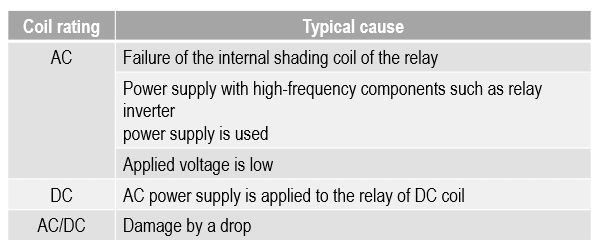

Typical causes

Countermeasure

- Replacement may be necessary.

- Consider a full-wave rectifier circuit by diode and a DC coil relay.

- Apply the relay's rated voltage.

Note

- Failure of the internal shading coil of the relay

In general, AC operation relays are equipped with a shading coil to prevent beat. However, if a small amount of foreign object (e.g. dust) gets caught in the pickup surface of the iron core and the iron piece, the balance of the pickup surface will be lost, causing beat. - High-frequency power supply such as an inverter power supply is used

If a relay is driven by a power supply with a high frequency, the iron loss in magnetic paths such as iron cores, iron pieces, and yokes will increase and the temperature will rise abnormally. Shading coils are designed to be optimal at 50 to 60 Hz, but their characteristics may vary with high-frequency components, causing beat. - Applied voltage is low (AC coil only)

In the case of AC coils, beat is generated when the applied voltage is low. This is because AC pulsates and there is a point where the voltage becomes 0 (zero) in synchronization with the power frequency.

When the voltage applied to the relay coil is gradually increased, beat (vibration) occurs near the operating voltage. - AC power supply is applied to the relay of DC coil

Because the DC coil does not have a shading coil, it causes beat as the AC voltage changes.

In addition, even when AC is fully rectified and used as DC, it may cause beat if the ripple factor is high.

The AC coil has a groove on the magnetic pole surface of the iron core, and a shading coil is installed on one side of the magnetic pole surface. Shading coils, also called copper rings, can shift the phase between the attraction force due to the magnetic flux flowing through the unshaded iron core and the attraction force due to the magnetic flux flowing through the shaded iron core. With this combined attraction force, even in AC where the voltage drops to zero in synchronization with the power supply frequency, no beat will occur as long as the proper coil voltage is applied.

(There is no beat when DC power is applied to the relay of the AC coil. However, the coil current increases.) - Output pulse failure driving relay with IC output (comparator)

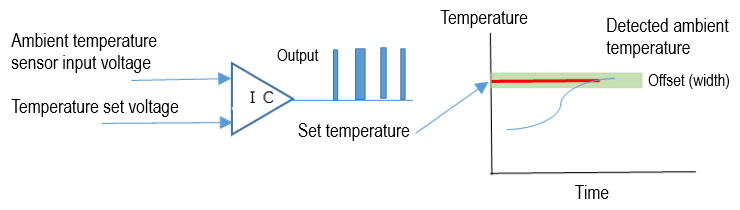

An offset width is required for ICs (comparators) that detect the temperature and output based on a comparison with the set temperature.

If there is no offset (IC ON/OFF width), the relay will cause beat when the IC output is continuously turned ON and OFF.

* Make sure that the circuit has the offset.

- Damage by a drop

When a strong impact such as dropping occurs, the iron core and yoke in the coil part may deform or be inclined, resulting in distortion in the pickup accuracy of the iron core and the iron piece. This creates a small gap and generates beat (noise) vibration when voltage is applied to the coil. (DC coil does not generate beat and vibration.)

Regarding to malfunction examples and countermeasure for relays, refer to The SOLUTIONS [General-purpose Relay Edition].

Quick tips

Check the voltage waveform that matches the relay coil rating before use.

| Product category | Relays Signal Relays Power Relays |

|---|---|

| Classification | Trouble shootings |

| Related keywords |

|