Talk between Mr. Hiroya Tanaka Professor at the Faculty of Environment and Information Studies, Keio University ×

Mr. Masahiko Ezaki Managing Executive Officer, Company President of Device & Module Solutions Company

We don't need "environmental friendly commitments" that are all talk.

How to concretely promote environmental efforts within the manufacturing industry.

Due to the global rise in environmental awareness, environmental considerations, including decarbonization, are having a direct impact on the business of manufacturing companies. What is the role of manufacturing in this situation?

All manufacturing companies are now required to manufacture products that lead to both business growth and environmental considerations. How should companies respond and take action with addressing environmental issues?

Mr. Hiroya Tanaka, professor at the Faculty of Environment and Information Studies, Keio University, who is seeking new ways of manufacturing such as through 3D printers while also appealing for the establishment of circular manufacturing centered on the "Leap Cycle" and Mr. Masahiko Ezaki, Managing Executive Officer, Company President of Device & Module Solutions Company (appointed on April 1, 2023), who has the goal to achieve carbon zero at OMRON while also helping other companies achieve similar goals, and who believes that using the right device and modules is vital to achieving those goals, talked about how manufacturing should consider its impact on the climate, and promote its efforts.

Table of contents

- What is a society that achieves both resource recycling and decarbonization?

- People's awareness of the changing "environment" and business requirements

- Working backwards from social issues to solve them with device and modules

- Response to high costs due to environmental response through digital transformation and value-added enhancement

What is a society that achieves both resource recycling and decarbonization?

First of all, please introduce each of your activities and environmental initiatives.

Mr. Hiroya Tanaka

Professor at the Faculty of Environment and Information Studies, Keio University, Director of Digital Manufacturing and Design Research Center for Emergent Circularity, Keio University Global Research Institute, Research leader of COI-NEXT (from 2021 onward), a project of the Ministry of Education, Culture, Sports, Science and Technology, "Co-creative innovation platform toward digital-driven leaped circular society"

Tanaka:I am conducting research on 3D printers and resource recycling. For about 15 years, I have been researching and developing 3D printers along three axes: material diversification, manufacturing speed improvement, and size expansion, and working on the expansion of various applications. Through these activities, I have come to believe that research on "returning" things to materials will eventually become necessary next to research on "making" things. Until now, the concept of "returning" things has been called "recycling", but there is more flexibility which leads to more human creativity through the introduction of 3D printers in this process. We have named this concept "Leap Cycle" and are conducting various research and development, and demonstrations.

It was the "Everyone's Podium Project" that inspired this concept. The purpose of this project was to create podiums for the Tokyo 2020 Olympic and Paralympic Games with 3D printers using crushed used plastic containers, and I served as the design supervisor for this project.

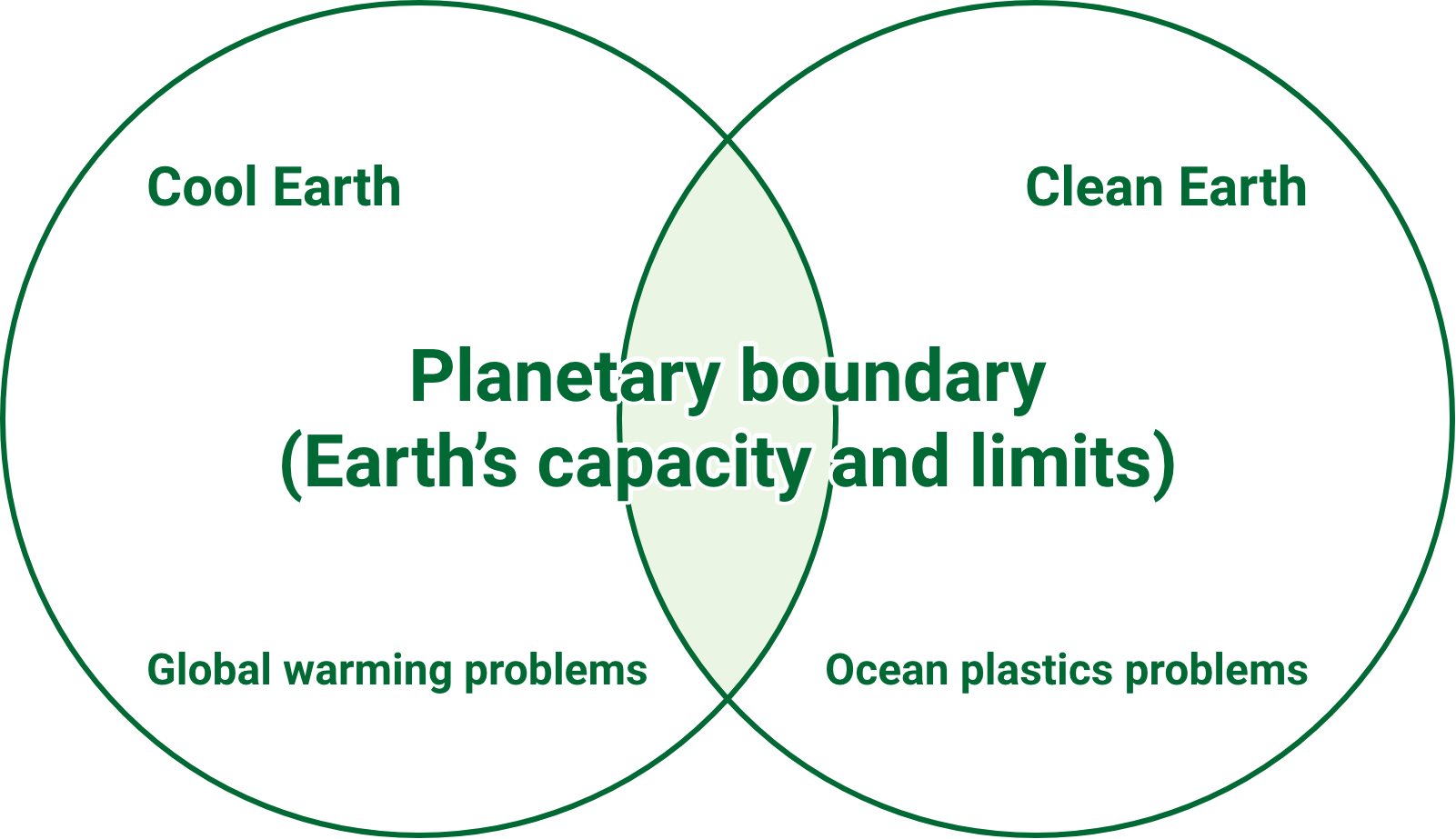

As an extension of this project, we are currently in the trial-and-error stage to create a system that achieves both decarbonization and resource recycling. When we look into the measures to address environmental issues, there are many measures that have a "regressive" relationship between resource recycling and decarbonization. The problem is that as more effort is put into collecting waste materials for resource recycling, more CO2 is generated during the transportation process.

As an idea to solve this problem, we are promoting compact circulation "within the region" in collaboration with local governments. Furthermore, there is a hypothesis that resource circulation is not only environmentally valuable, but also valuable in improving the well-being of the people who participate in it. I would like to create a citizen-participatory circular society, so I say, "We should aim for a human-centered ‘circulator society’ that lies beyond the ‘circular society’ in the future.”

Provided by Prof. Hiroya Tanaka (reconstructed based on Cabinet Office data)

Ezaki:OMRON is taking initiatives to solve three social issues, "achieving carbon zero," "implementing a digital society," and "extending healthy life expectancy" in its long-term vison, “Shaping the Future (SF2030)"(*1)

From among these three, Device & Module Solutions Company focuses on two of them, "achieving carbon zero" and " implementing a digital society" and is working to create new value that will contribute to the spread of new energy and high-speed communication.

In conjunction with the start of OMRON's long-term vision, the mission of Device & Module Solutions Company has been defined as, "With our ‘connecting’ and ‘switching’ technologies, resolve social issues with customers. In the environmental domain, which represents the value provided in the environmental domain, we are not only working to decarbonize the production of our own products from a medium- to long-term perspective, but also optimizing society as a whole by involving our customers, suppliers, and other stakeholders. We are actively disseminating the value and direction provided by Device & Module Solutions Company by making various efforts, such as launching a new special website "Carbon Zero."(*2) where we provide more information regarding our products, services and our efforts.

(*1) Shaping the Future (SF2030): OMRON's long-term vision launched on April 1, 2022, which aims to “continue creating innovation driven by social needs through automation to empower people.”

Mr. Masahiko Ezaki

Managing Executive Officer, Company President of Device & Module Solutions Company

(*2) Introduction website of "DMS GREEN PROJECT" which OMRON Device & Module Solutions Company establishes as a "Carbon Zero" initiative.

[Click to go to the website] Provided by OMRON

People's awareness of the changing "environment" and business requirements

A podium for the Tokyo 2020 Olympic and Paralympic Games, which was made from used plastics using a 3D printer.

After use, the podiums are reused at parks and other facilities in various places. Provided by Prof. Hiroya Tanaka

How do you feel about the recent rise in environmental awareness?

Tanaka:I feel that "people's way of thinking" is changing. In the "Everybody's Podium Project" I mentioned earlier, we were able to collect 24.5 tons of used plastic containers. We were surprised because we did not expect to collect that much. As far as students are concerned, I feel that they are extremely environmentally conscious. Current first-year college students were born in 2005, and I hear that this generation has already learned about the SDGs in junior high school and elsewhere. For these students, working "for the global environment" is a great motivation.

Ezaki:As a consumer, I am definitely becoming more familiar with environmental initiatives. On the other hand, business-wise, we are receiving an increasing number of inquiries from customers asking us to disclose the amount of CO2 emitted in the manufacturing process. In Europe, there are business negotiations for digital product passports that share various information on the product lifecycle, such as the product's origin, materials used, and recyclability, so I feel that the creation of a framework for integrating environmental responsiveness with business has progressed rapidly over the past few years.

Under these circumstances, I feel that companies are being asked to put their environmental initiatives into concrete goals and actions, rather than limiting them to empty rhetoric. I also feel that there is an expectation that the evolution of products and technologies can contribute to solving problems. To this end, we are taking on the challenge of “DMS (*2) GREEN PROJECT.”

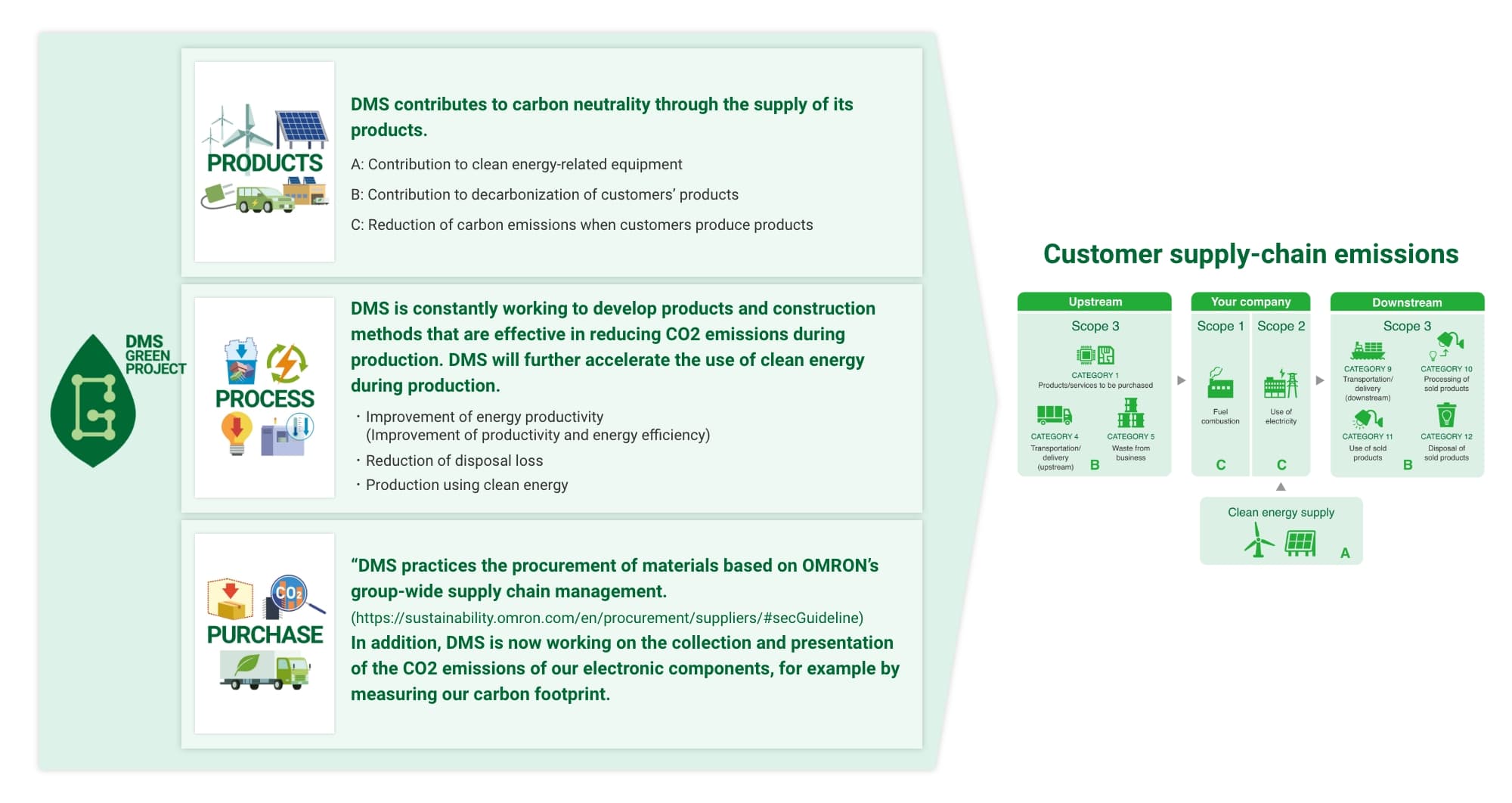

As I previously mentioned, we are not only working to achieve decarbonization during the production of our own products as the value provided by "Carbon Zero," but also working with our customers and suppliers to incorporate this into concrete actions as a project that will contribute to the achievement of carbon zero.

(*2) DMS: Abbreviation for OMRON Device & Module Solutions Company

We will take on the challenge of achieving carbon zero throughout the entire value chain by linking the three initiatives of PRODUCTS, PROCESS, and PURCHASE from upstream to downstream in the supply chain. Through our device and modules, we will support our customers save energy in their products and labor in their production processes. Furthermore, regarding our own production processes, we plan to complete the introduction of 100% renewable energy at our domestic production bases of Device & Module Solutions Company by FY2024, promote the visualization of CO2 emissions at the component level, and disseminate information. The first step is to work on achieving carbon zero for Scope 1 and 2 of the GHG protocol, and then expand to Scope 3. We will accelerate the provision of products and solutions that encourage the achievement of carbon zero by declaring these concrete activities.

Overall view of the DMS GREEN PROJECT. OMRON Device & Module Solutions Company, which itself plays a part in the supply chain, contributes to the achievement of carbon zero on a global scale. [Click to enlarge] Provided by OMRON

OMRON’s group-wide supply chain management: https://sustainability.omron.com/en/procurement/suppliers/#secGuideline

Working backwards from social issues to solve them with device and modules

I feel that there are few cases where electronic component manufacturers talk about their direct efforts to address social issues, but why does OMRON reiterate its commitment to the "environment"?

Ezaki:Device and modules such as relays, switches, connectors, and sensors that we provide are small in size, but they are incorporated in many electronic devices. CO2 emissions from device and modules are the accumulation of emissions from device and modules in the product. Therefore, if we can reduce the CO2 emissions of the products we provide as planned, then we will be able to significantly reduce the CO2 emissions in our customers' products and services.

Until recently, we tended to focus on solving our customers' product challenges, and only provide device and modules that meet their specifications. However, during the process of formulating the long-term vision, some members on the frontline voiced their desire to solve social issues more directly and wondered if we could directly approach social issues. In the meantime, the atmosphere is more lively than before as many members have come up with concrete proposals.

Under these circumstances, we worked backwards from the environmental problem, which is a social issue, and incorporated into our business strategy what our products should be (PRODUCTS), what our manufacturing process should be (PROCESS), and what our purchasing activities should be (PURCHASE). We believe that we can create solutions faster by identifying the issues that lie beyond our customers' products, proposing and disseminating proposals more quickly, receiving feedback from society and our customers, and making updates. We are considering not only providing products to our customers, but also offering them as a solution that contributes to the achievement of carbon zero. For example, we will first propose products that contributes to reducing CO2 emissions of electronic devices, products that are produced with 100% renewable energy, and products that visualize the carbon footprint. In addition, through dialogue, we intend to materialize this into products that lead to value for society and our customers.

However, for these efforts to really take root, it is necessary to involve not only ourselves but also our customers and suppliers. By taking a step forward and making concrete proposals, I hope that we can create a form for solving environmental problems through decarbonization and our business activities.

Professor Tanaka mentioned that students nowadays have a high level of awareness for environmental issues, and considering "involvement," we are very grateful for such growing awareness on the general consumer side. If consumers become more aware of the need to use more environmentally friendly products, it will spur a movement among our customers to choose environmentally friendly products as well. It would be wonderful if connections could be made in both directions toward such an ideal society.

Tanaka:I understand that you are trying to envision the medium- to long-term future and move toward that future while involving various stakeholders in the process. Because we live in a time when the future is unpredictable, it is extremely important for us as a leader to set goals that are one step ahead and try to drive the future, and I feel that such actions will really be needed in the future. As I mentioned earlier, environmental problems are complexly intertwined with various factors in a regressive relationship. In this context, thinking only about the immediate future will not lead to a change in the situation. On the other hand, I feel that one of the strengths of OMRON's device and module solutions company’s components business is that "OMRON's products are used in many electronic devices" and that there is a sense of scale in which a single component can dramatically change society. Using OMRON’s device and modules will lead to the widespread use of environmentally friendly functions become possible, and this gives us the ability to take action that leads to realistic solutions to global issues.

These days, most companies have a policy of being "environmentally friendly.” However, what I always talk about with my students is to see what they are doing as future concrete initiatives. The word "environment" encompasses a wide range of issues, including global warming, biodiversity, resource recycling, and work style reform. And each is in a partially regressive relationship. As we approach things more seriously, difficult things that cannot be solved by fine-sounding words become more apparent. I hope that companies will increase opportunities to promote understanding on the consumer side by disseminating information on whether or not they are working on these difficult areas without giving up. It would be ideal if we can use the environment not just as a slogan, but if we can all become more environmentally literate.

Response to high costs due to environmental response through digital transformation and value-added enhancement

One aspect that we have to grapple with is that there are business risks associated with environmental response, such as higher costs. How should we consider this point?

Ezaki:Many companies have been rather passive and "defensive" in their environmental response. We want to proceed from now on is an "offensive" environmental response and continue to grow as a company in line with this offensive stance.

Adding new environmentally friendly technologies and solutions to the device and modules we currently offer may increase costs. In order to solve this problem, we will improve the efficiency of the process itself by utilizing information technology and digital transformation. In addition, we believe that we can gradually overcome the problem by clearly demonstrating the business value created by environment-friendly products. By using our products, we would like to create a model that leads to the reduction of power consumption in our customers' products, thus leading to medium- and long-term benefits for the end users. It is important to create value by comprehensively considering our company’s products, our customers' products, and the environment for general consumers.

Tanaka:Even if the price of a single electronic component rises, looking at the service as a whole, you are creating a structure where value is being added somewhere. If that is the case, are you changing your manufacturing structure and system, for example, by integrating engineers who design products and engineers who design the entire service?

Ezaki:Yes, we are. Our traditional organization was based on a division of labor, including sales, marketing, and development. However, when thinking about what kind of product should be created by working backwards from the value, rather than having each organization share the responsibility, concurrent activities are being incorporated from the beginning, with each organization contributing from its own perspective.

Tanaka:That is an interesting approach. I think there will be many difficulties because of the "offensive" environmental response. I think students nowadays see that we are taking concrete action while taking on the challenge of balancing the difficulty of our environmental response with our business. It may seem modest, but I believe that such efforts will resonate with students.

Ezaki:Thank you very much. Although there are things that we cannot achieve instantly, we would like to move forward with our activities by proposing and disseminating our opinion around social issues, and by responding to feedback from society and customers. However, there are limits and waste in advancing these efforts in the components business alone. That is why it is necessary to involve suppliers and customers in the entire supply chain. We will take the lead in contributing to the realization of a carbon zero society through our technologies, device and modules, and solutions, while involving many stakeholders. In order to accelerate the realization of such a society, we would like to increase the number of partners with the same vision who can work with us on challenges with no one correct answer.

Thank you both for your cooperation in this interview.