vol.248 September 2021

![]()

Contributing to better power transmission efficiency of power conditioners.

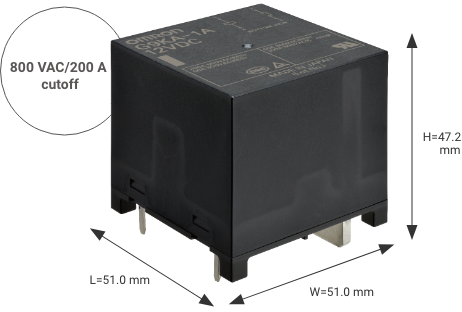

To contribute to solving heat generation issues caused by higher capacity and higher current in distributed power conditioners, we have released a compact 200A high-capacity relay with industry's top class*1 ultra-low contact resistance (0.2 mΩ) that reduces heat generation.

Power Relay G9KA

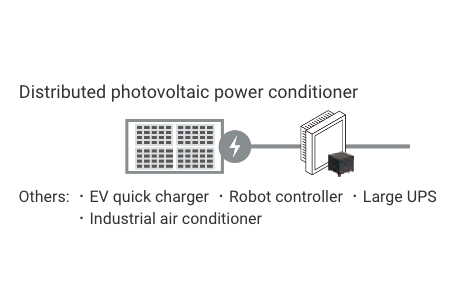

Applicable for a wide variety of applications

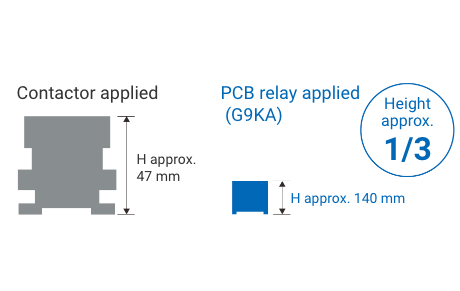

Contributing to device miniaturization and space saving

G9KA Ultra-low contact resistance 0.2 mΩ

Effects and performance with 0.2 mΩ

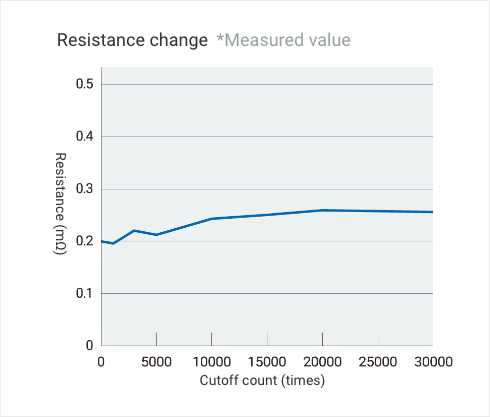

By enhancing the manufacturing quality of the contact material and structure, we have achieved the industry's top class*1 ultra-low contact resistance of 0.2 mΩ.

Furthermore, it is now possible to maintain the low contact resistance capability, which is the key to the transmission efficiency of the power conditioner, until the end of its electrical performance.

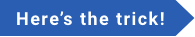

Suppressing temperature rise when energized

※The above figure shows the results of thermal simulations conducted at OMRON under the following conditions. Simulation conditions: 480VAC/200A, ambient temperature 85°C, fans, ducts, and heat sinks used, one on board.

※The temperatures listed here are simulation results with relays and terminal blocks mounted on the board. In actual use, you should use fans or heat sinks to lower the board temperature to the upper limit.

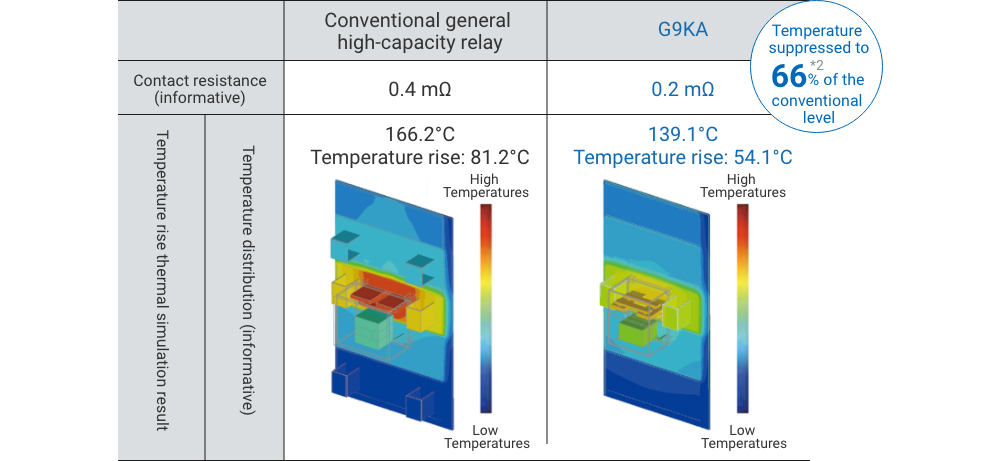

Keeping low contact resistance capability until the end of electrical performance

<Evaluation condition>

Switching conditions (resistive load): 800 VAC, 50 A connected, 200 A energized, 50 A cutoff

Coil voltage conditions: When connected, 12 V (100%) applied then maintained at 6 V (50% holding voltage)

Ambient temperature: 85°C

Contact resistance test condition: 200 A 30 minutes after energizing

*1. According to OMRON's research in July 2021.

*2. Comparison of temperature rise at fixed contacts.

* Contents as of August 2021.

In the interest of product improvement, specifications are subject to change without notice