vol.288 January 2025

Improved "heat suppression" and "heat dissipation" solve heat problems caused by high capacity.

With the trend towards multifunctionality and high functionality, there is a growing demand for high-capacity support in various types of equipment. However, heat generation issues become more prominent as the capacity becomes higher. A relay generating a large amount of heat can interfere with the functionality of the equipment. Therefore, it is essential to take measures to prevent the relay from generating heat. However, taking countermeasures against heat generation can increase the size of the relay and require additional parts. OMRON contributes to the realization of safety and security with relays that suppress and dissipate heat for higher capacities.

OMRON's relays solve heat problems by adopting heat suppression and dissipation technologies.

|

If a relay generates a large amount of heat ▶ |

The improvement of heat suppression and dissipation performance is essential,otherwise it can lead to equipment deterioration and malfunction.

|

|---|

Heat suppression

Heat suppression

Suppresses resistance of the current-carrying part

Heat suppression by increasing cross-sectional area

Increased cross-sectional area of the current-carrying part

(terminal part)

G6QE

1.2 mm2 × 2 (0.8 × 1.5 mm)

480 VAC, 36 A

Load switching

G6QG

2.4 mm2 × 2 (0.8 × 3.0 mm)

480 VAC, 55 A

Load switching

Supports even larger currents

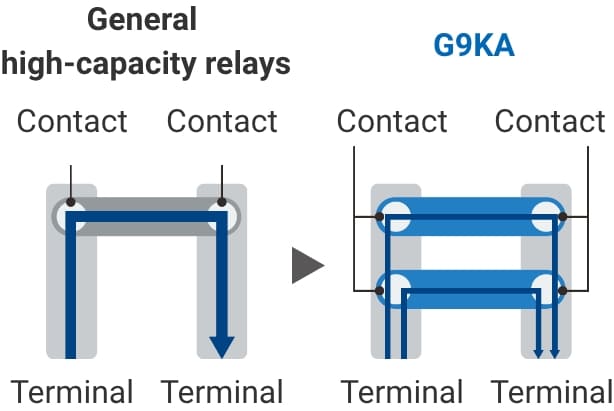

G9KA

45 mm2 × 2 (3.0 × 15.0 mm)

800 VAC, 260 A

Power interruption

G9KA-E

72 mm2 × 2 (3.0 × 24.0 mm)

1000 VAC, 300 A

Power interruption

Heat suppression

Heat suppression

Suppresses resistance of the current-carrying part

Heat suppression by dispersing current

Parallelized contacts to disperse heat without concentrating it

Heat suppression by improving materials and shape

Optimized contact material and shape to reduce contact resistance

Heat dissipation

Heat dissipation

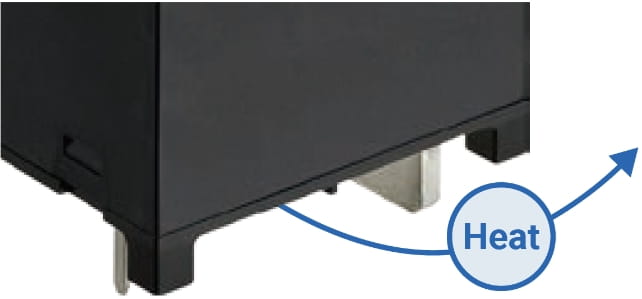

Ensures proper ventilation

Heat dissipation by improving ventilation

Improved heat dissipation by adopting a structure that ensures ventilation and by increasing the contact area between each terminal and the air

G9KA

The G9KA-E with a larger standoff structure allows for even greater ventilation

OMRON's power relays, born from the approach of “heat suppression” and “heat dissipation” improvement

Switchable 480 VAC, 40 A

Low initial contact resistance of 6 mΩ or less

4-pole power relay

G9KC

1-pole 480 VAC, 55 A

Load switchable

Compact, low-profile power relay

G6QG

G6QG

800 V 260 A / 1000 V 300 A cutoff and ultra-low contact resistance of 0.2 mΩ (initial) or less

High-capacity power relay

Click here for more information

G9KA

G9KA-E

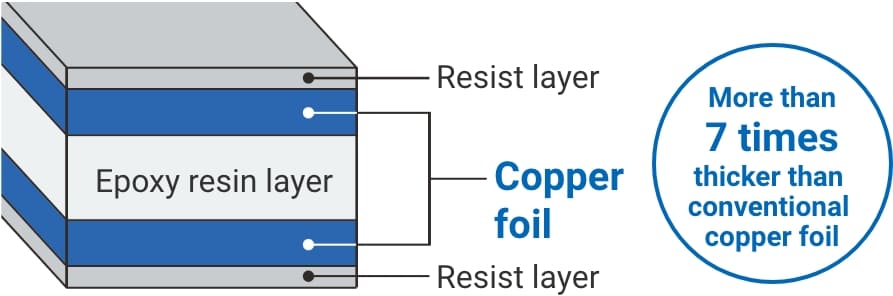

The use of heavy copper PCBs further improves heat suppression and dissipation.

Thicker copper foil facilitates current flow, suppresses heat generation, and dissipates heat.

* Contents as of December 2024.

In the interest of product improvement, specifications are subject to change without notice