Describes the unique characteristics of electronic components, malfunction causes and measures, in an easy-to-understand manner.

It can also be used as a preliminary prevention measure and a primary consultation tool when trouble occurs at any time.

Defect case studies

You can understand specific examples of defects that can be assumed from a particular phenomenon with photos.

Checkpoints for Prevention

Easy-to-understand explanations with illustrations are provided to avoid problems when setting up the product.

A must-have guide for your benefit. We have prepared PDFs for each product, so please download and use them.

* In case of a malfunction occurring, please return the part(s) to us as is (do not take it/them apart).

MOS FET Relay

Click to read contents

Contents

- MOS FET Relay - Failure Relationship Diagrams

- MOS FET Relay - Failure Events

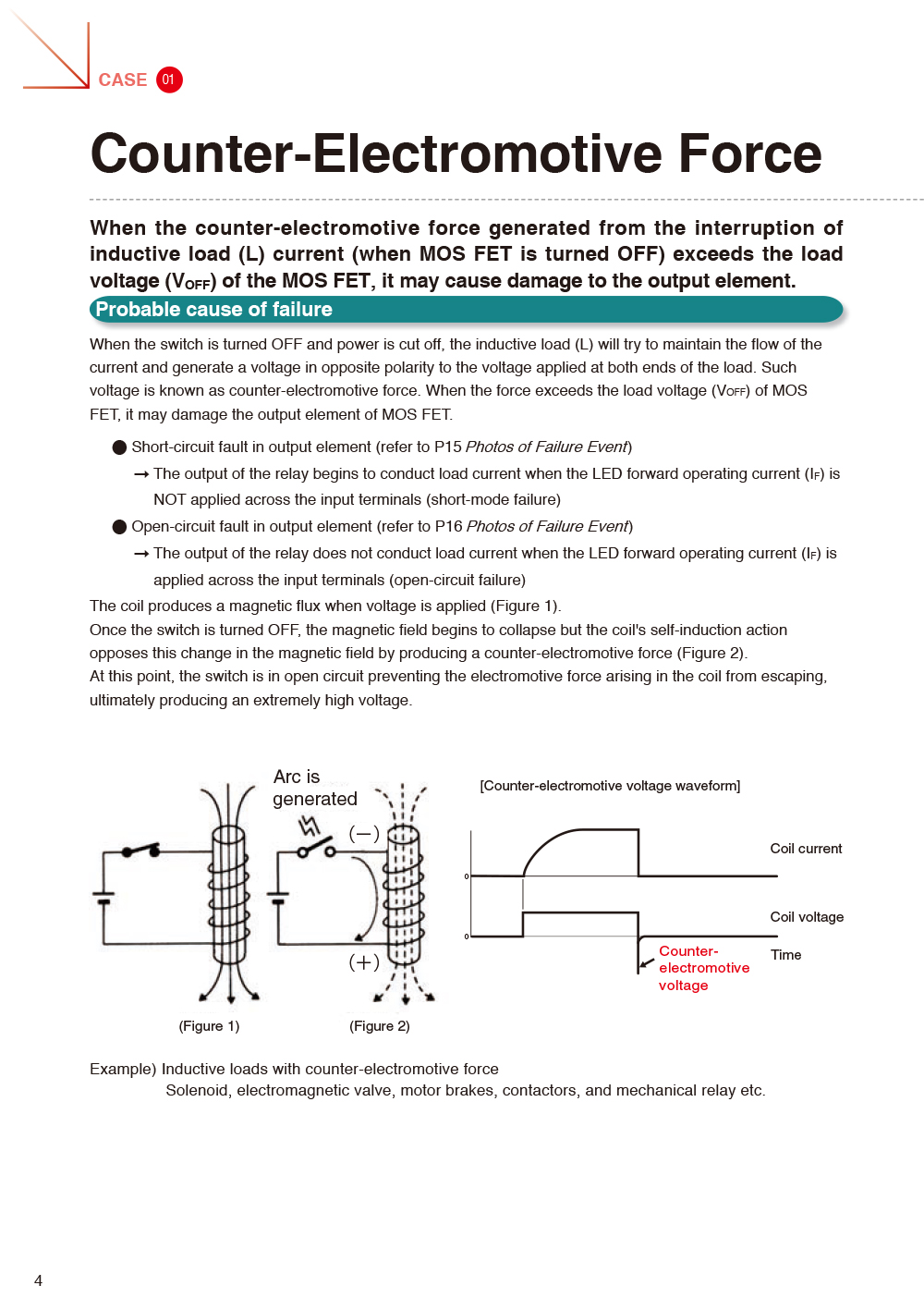

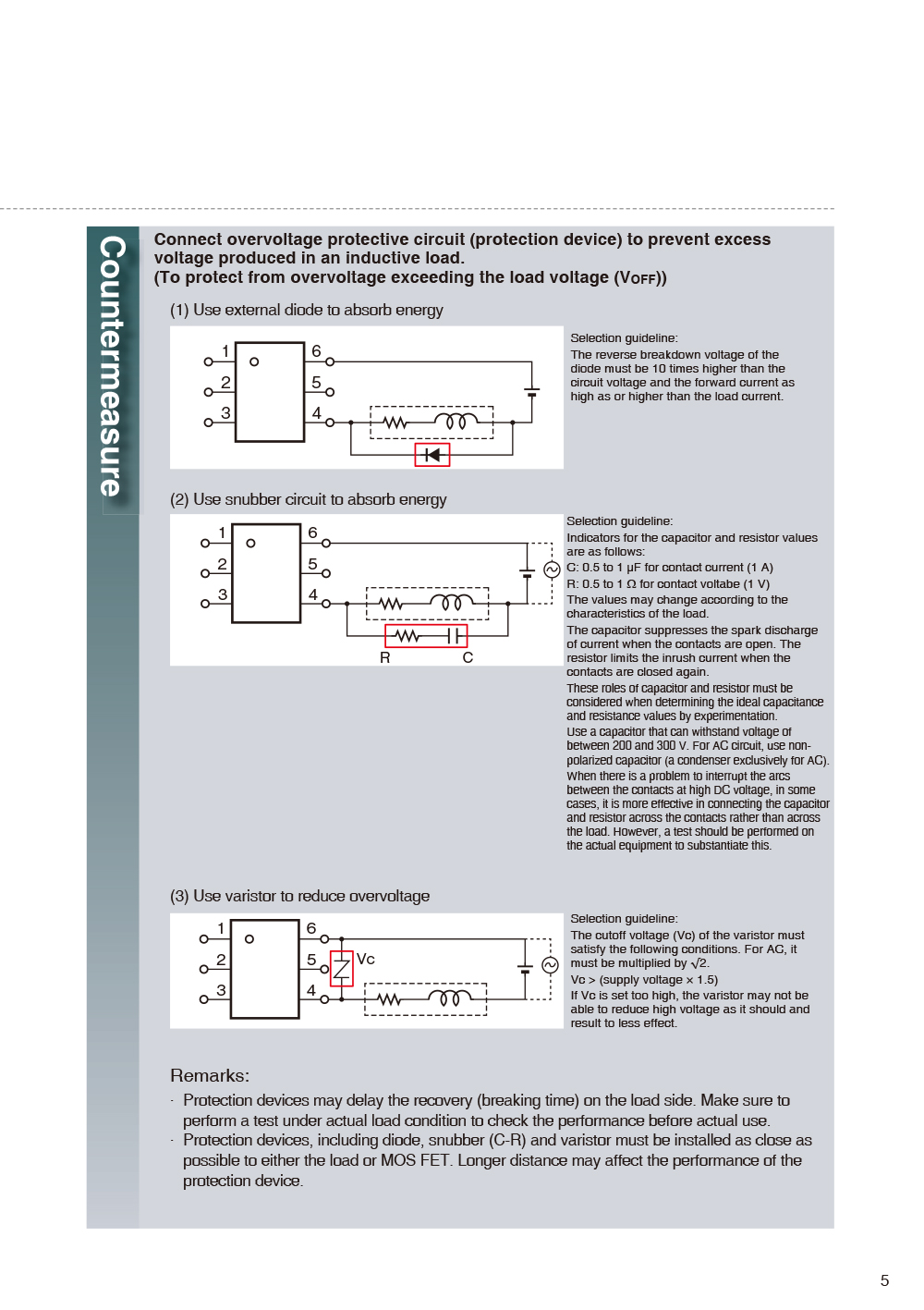

- CASE01 Counter-Electromotive Force

- CASE02 Voltage Surge (Input Side)

- CASE03 Ripple voltage

- CASE04 Inrush Current

- CASE05 Output Circuit Design Guideline

- CASE06 Input Circuit Design Guideline

- Photos of Failure Event

Mechanical PCB Relay Edition

Click to read contents

Contents

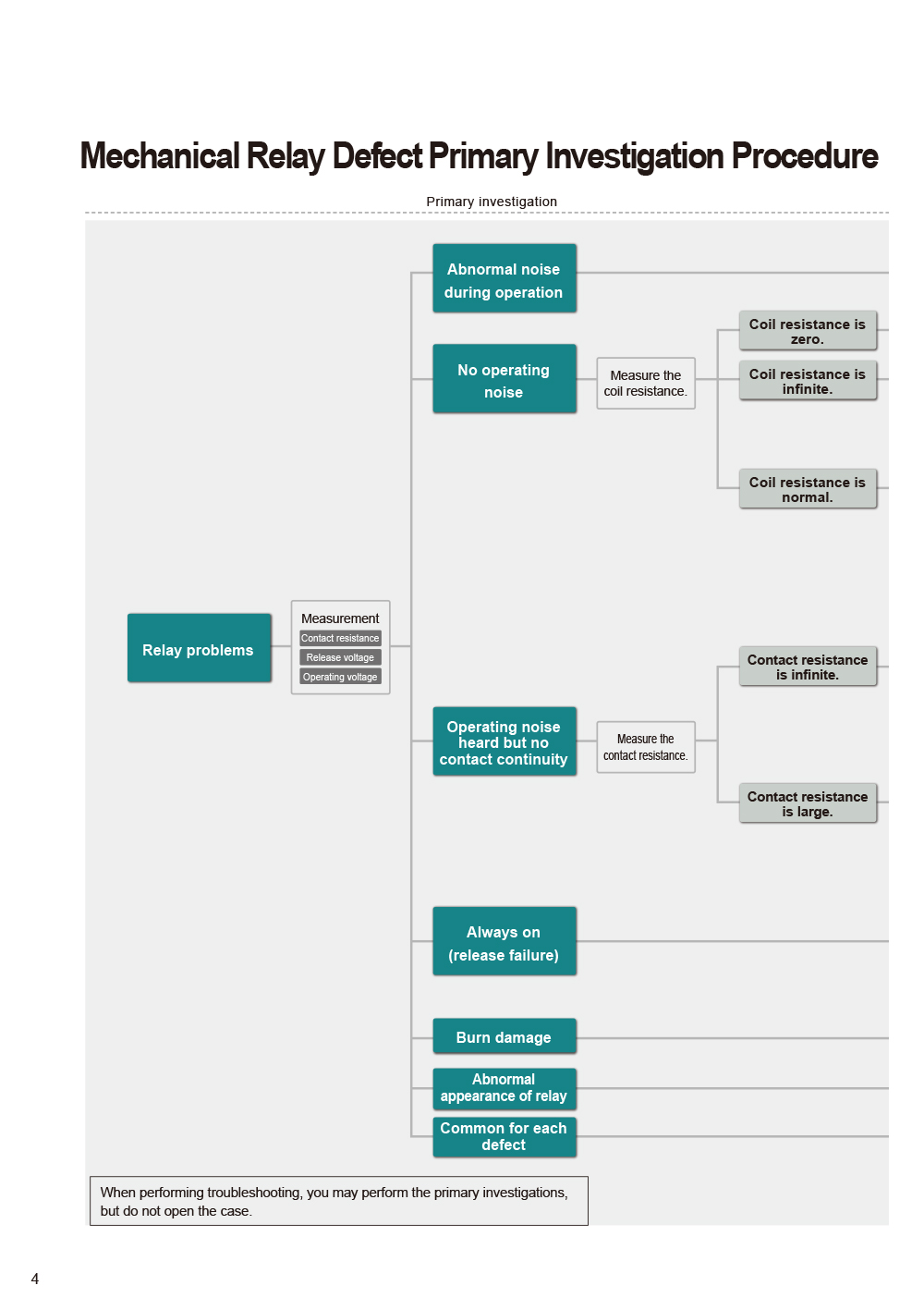

- Mechanical Relay Defect Primary Investigation Procedure

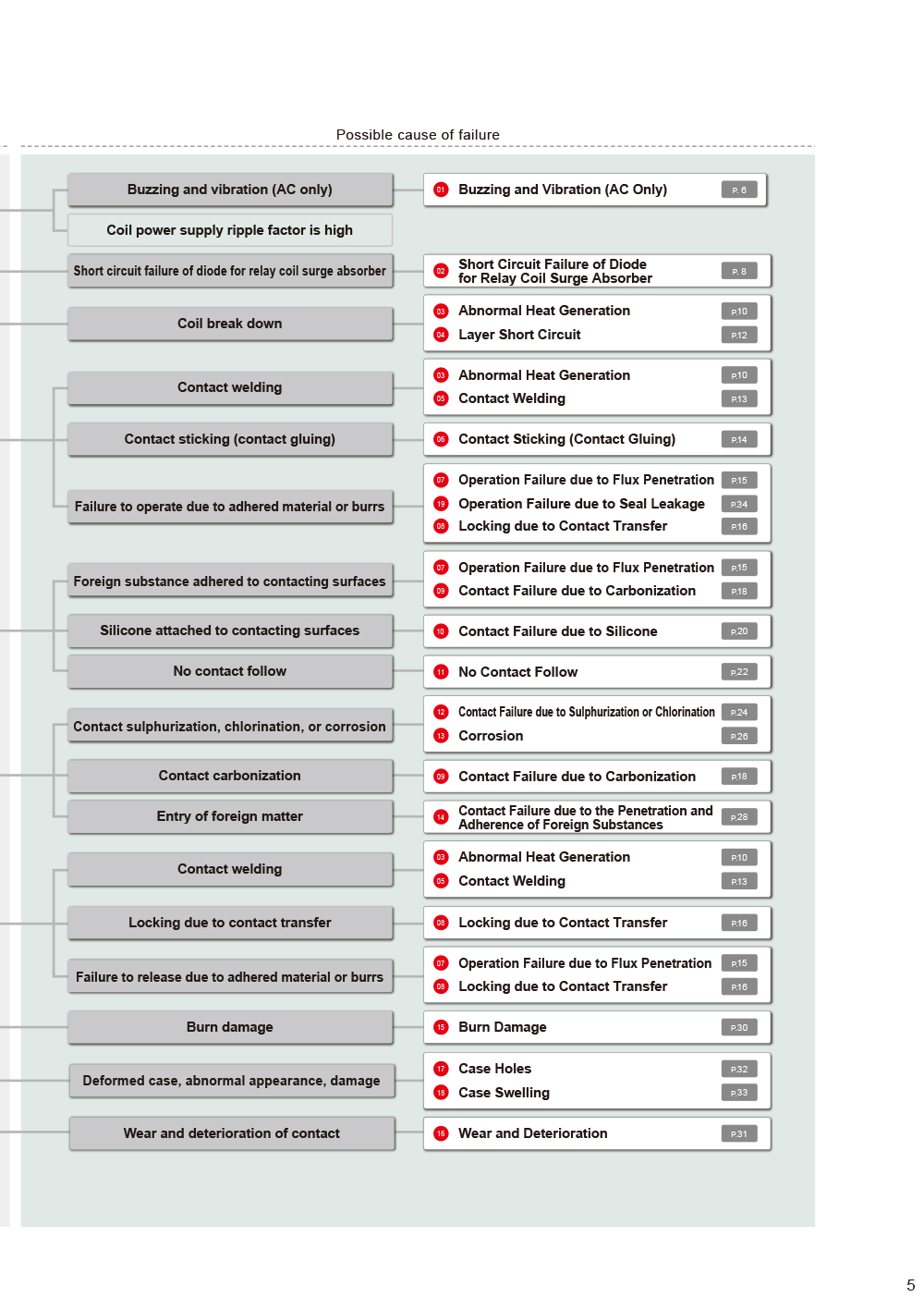

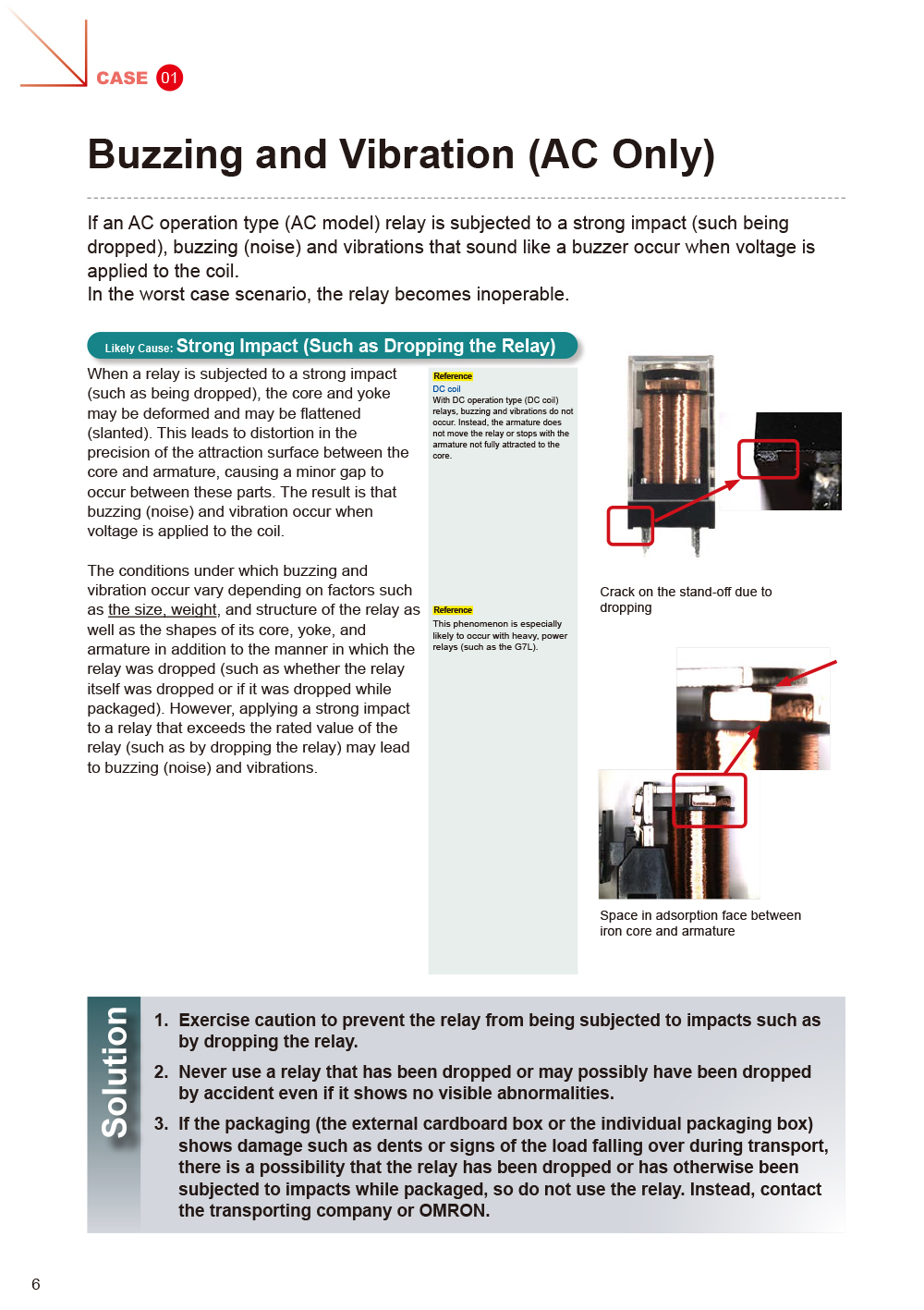

- CASE01 Buzzing and Vibration (AC Only)

- CASE02 Short Circuit Failure of Diode for Relay Coil Surge Absorber

- CASE03 Abnormal Heat Generation

- CASE04 Layer Short Circuit

- CASE05 Contact Welding

- CASE06 Contact Sticking (Contact Gluing)

- CASE07 Operation Failure due to Flux Penetration

- CASE08 Locking due to Contact Transfer

- CASE09 Contact Failure due to Carbonization

- CASE10 Contact Failure due to Silicone

- CASE11 No Contact Follow

- CASE12 Contact Failure due to Sulphurization or Chlorination

- CASE13 Corrosion

- CASE14 Contact Failure due to the Penetration and Adherence of Foreign Substances (Such as Dust and Insects)

- CASE15 Burn Damage

- CASE16 Wear and Deterioration

- CASE17 Case Holes

- CASE18 Case Swelling

- CASE19 Operation Failure due to Seal Leakage

- Relay Problem Cause Overview

Micro switch

Click to read contents

Contents

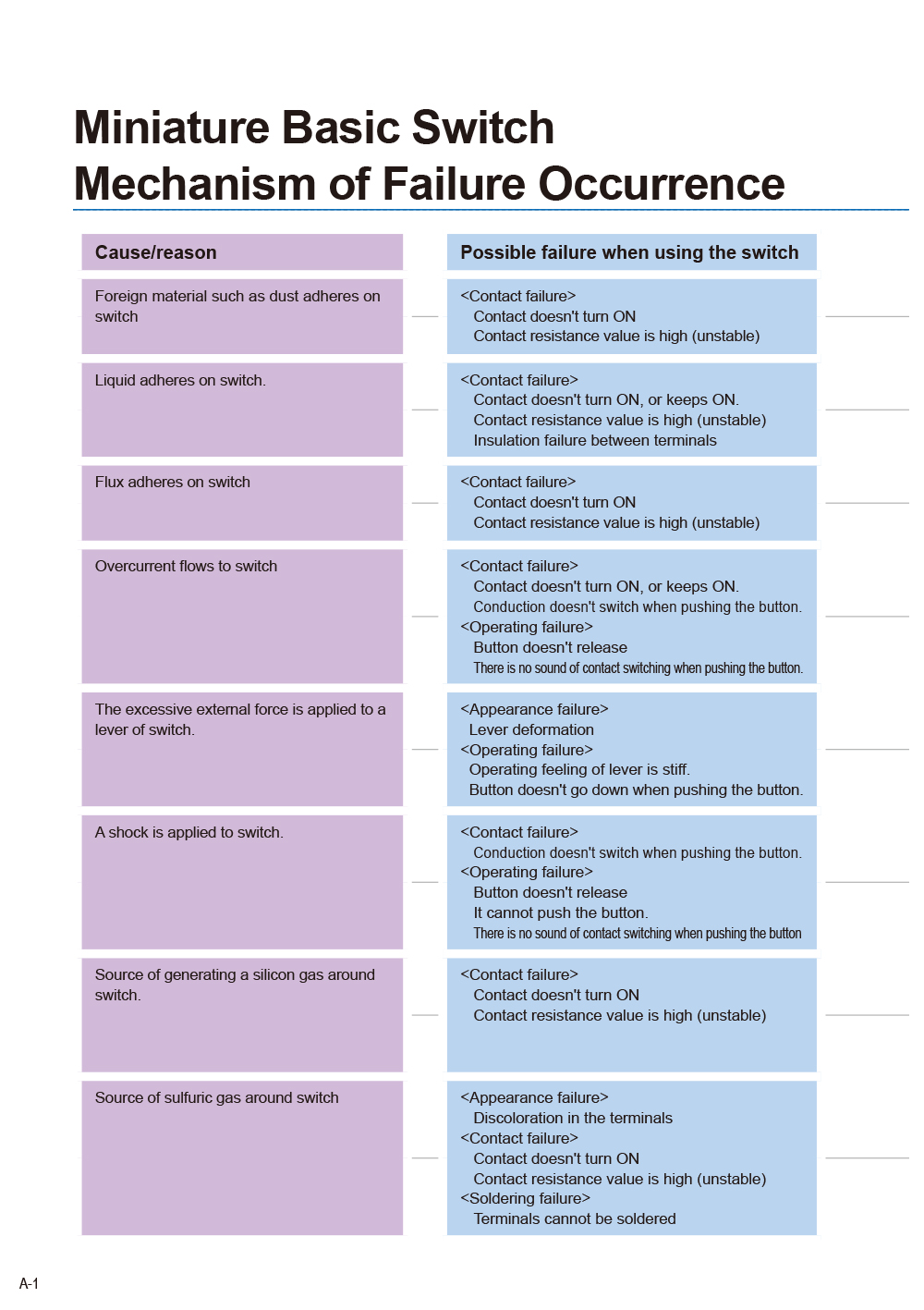

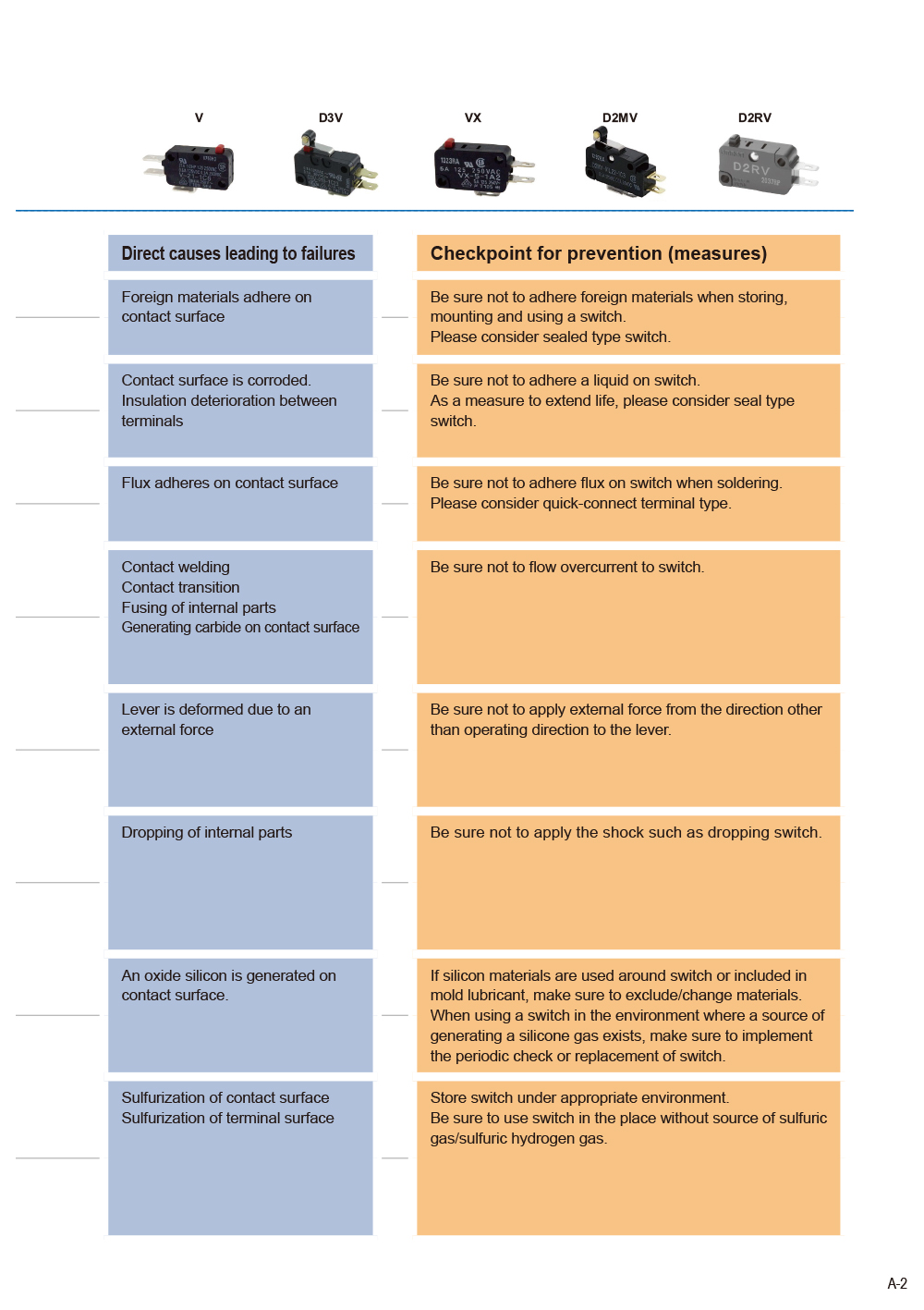

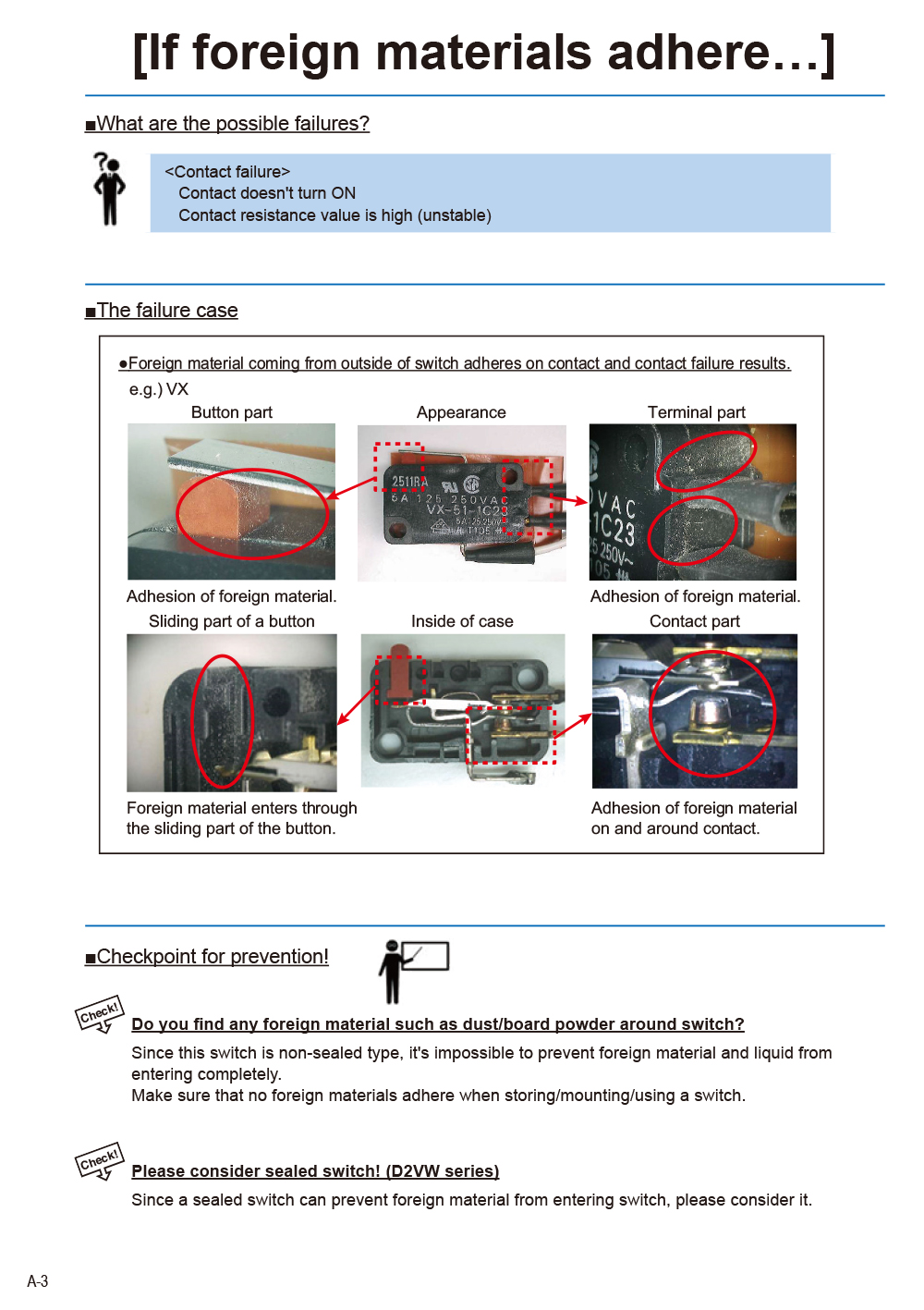

- Miniature Basic Switch

(V, D3V, VX, D2MV, D2RV) - Subminiature Basic Switch

(D3M, SS, SS-P, D2S) - Ultra Subminiature Basic Switch

(D2LS, D2FS, D2FD, D2F, D2MQ) - Sealed Basic Switch

(D2VW, D2SW, D2SW-P, D2HW, D2JW, D2QW) - Detection Switch

(D2A, D3C, D2X) - Reference document

Operation Switch

Click to read contents

Contents

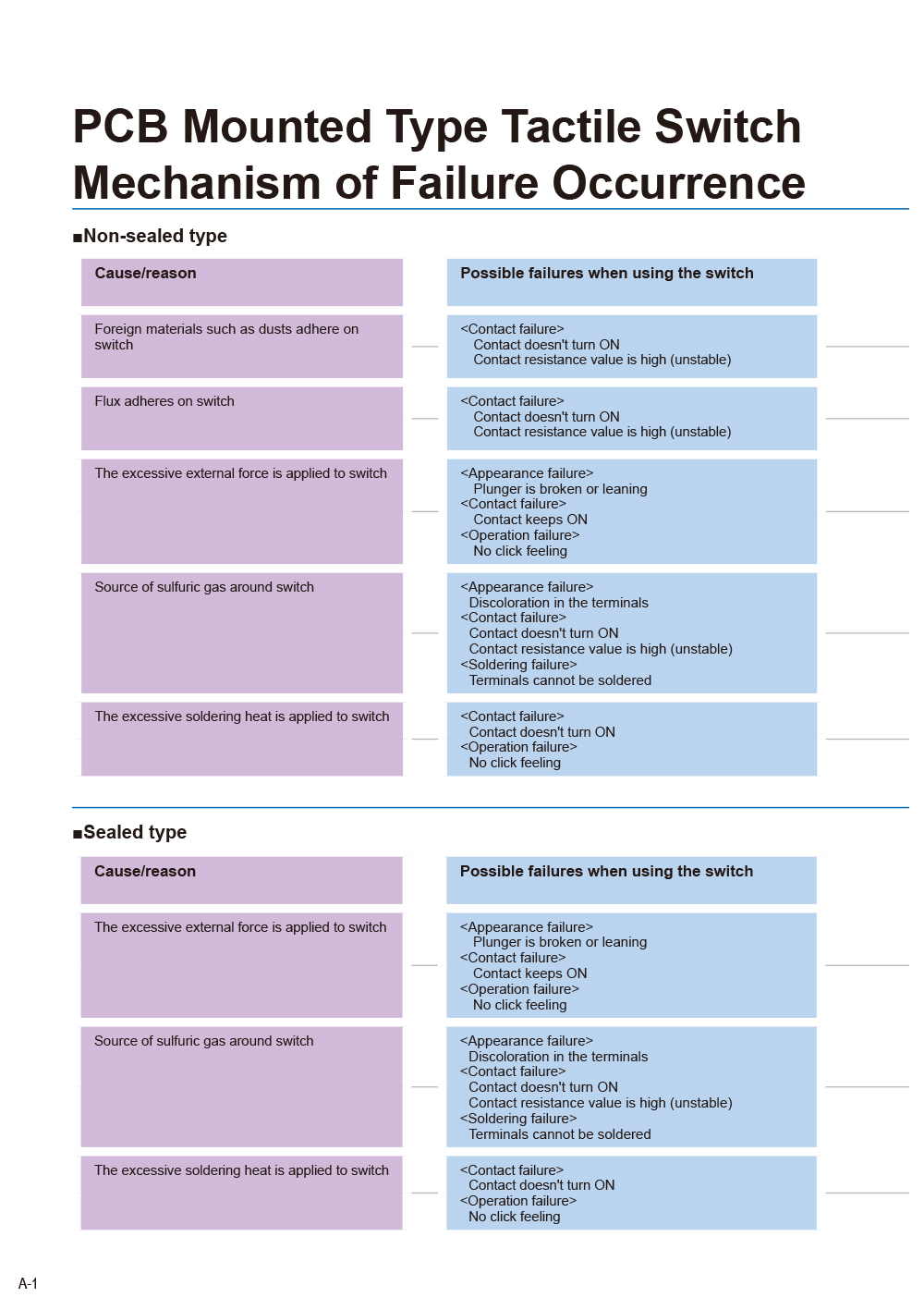

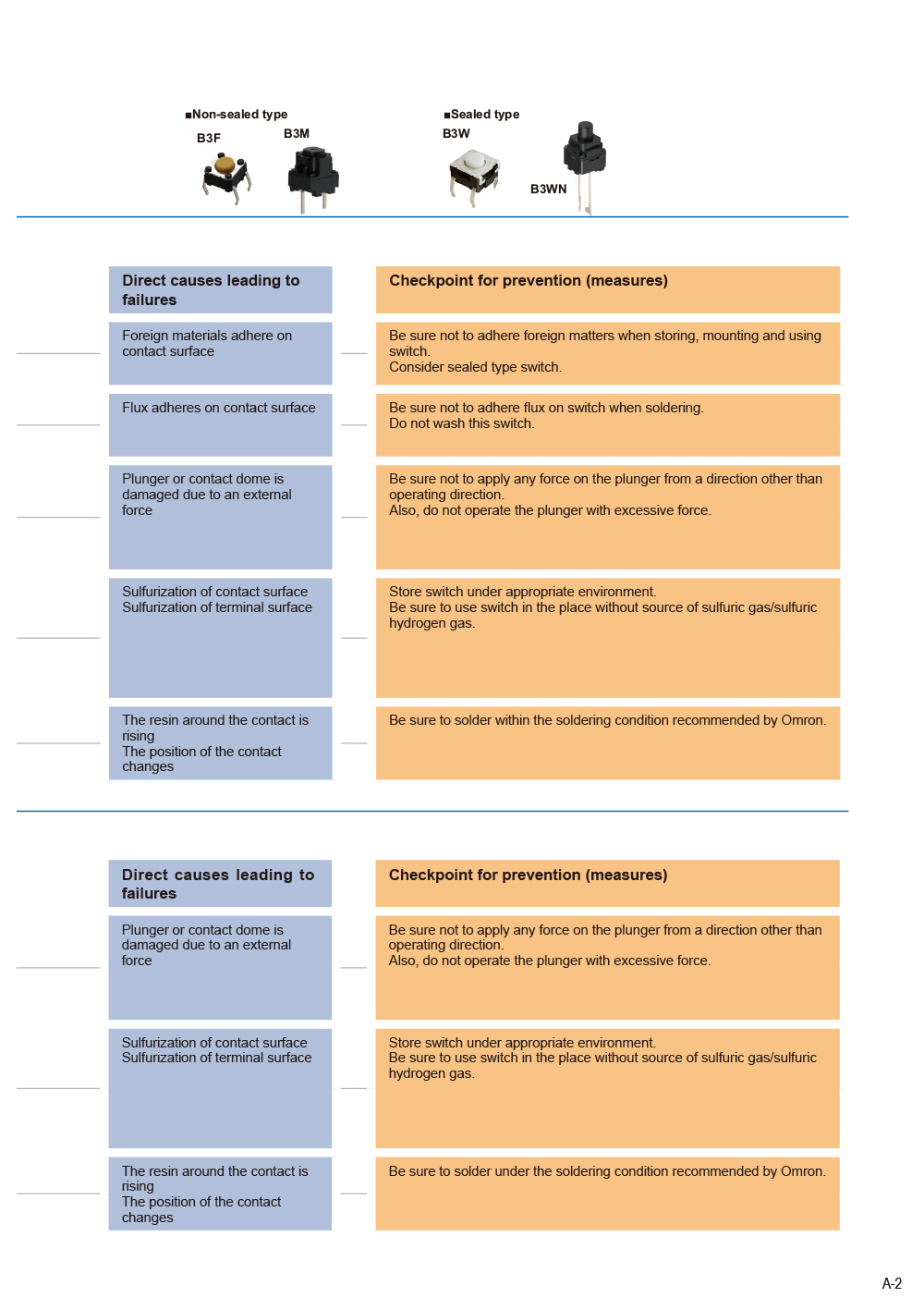

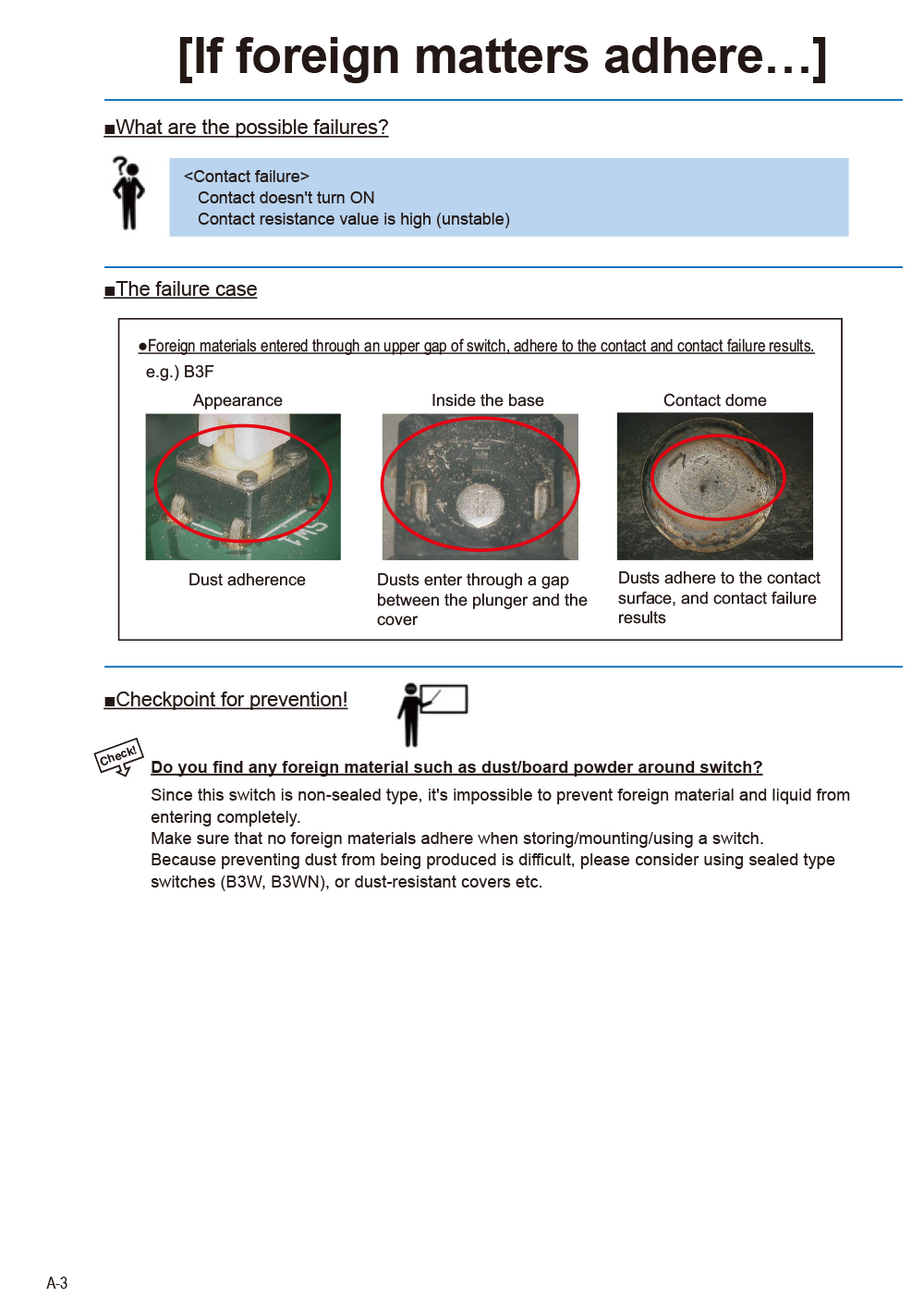

- Tactile Switch [PCB mounted type]

(B3F, B3M, B3W, B3WN) - Tactile Switch [Surface mounted type]

(B3FS, B3U, B3S, B3SN, B3SL) - Rocker Switch

(A8L, A8A, A8G, A8GS) - DIP Switch

- Slide DIP Switch

(A6H, A6HF, A6SH, A6SN, A6T, A6TN, A6D, A6E-N) - Piano DIP Switch

(A6HR, A6SR, A6TR, A6DR, A6FR) - Rotary DIP Switch

(A6K / A6K□, A6R / A6R□, A6A,

A6C / A6CV)

- Slide DIP Switch

- Reference material

Connector

Click to read contents

Contents

- Items Common to All Connectors

- If I Apply a Force to a Terminal...

- If the Electrical Contact Is Deformed...

- If I Apply an External Force After Soldering...

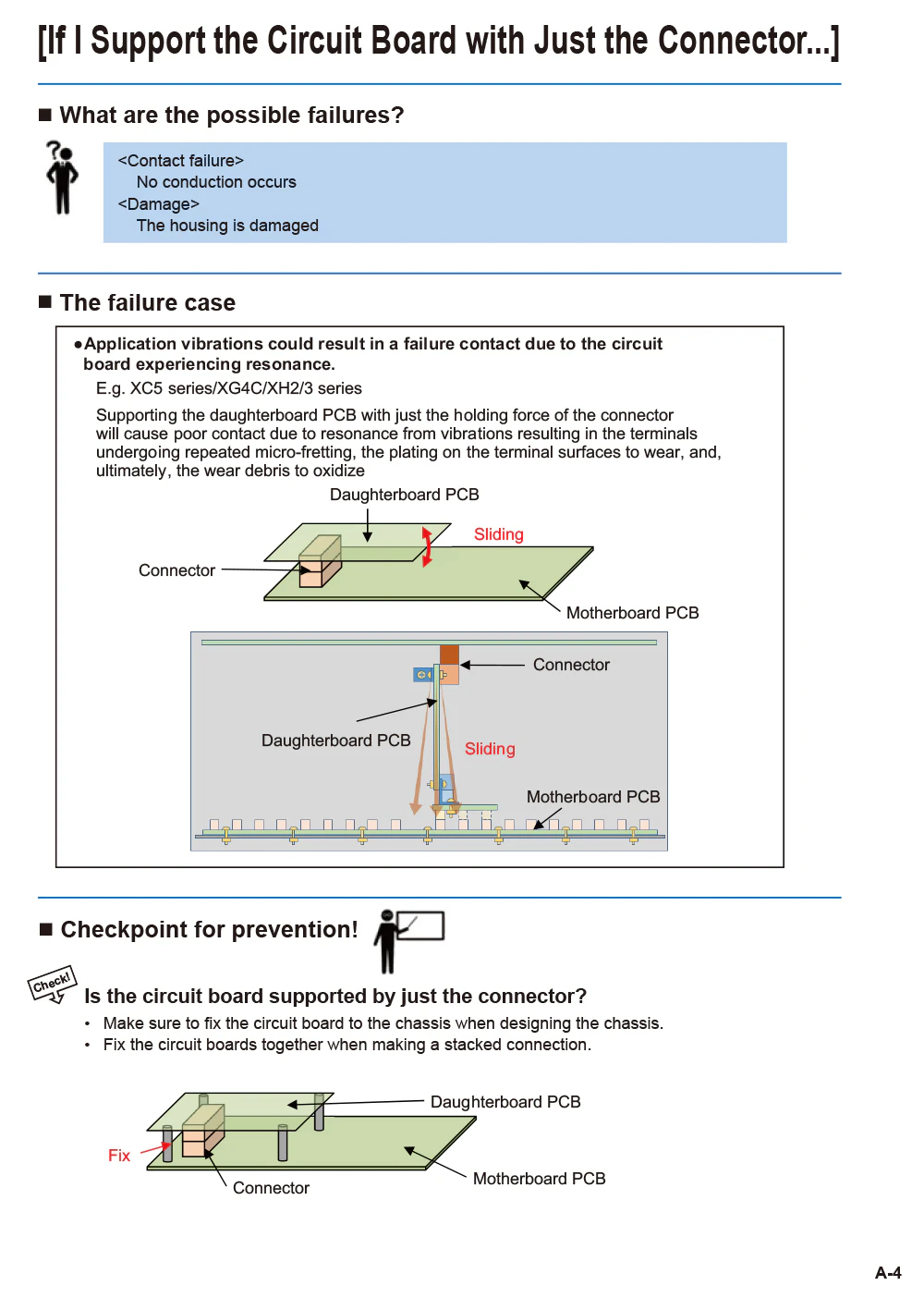

- If I Support the Circuit Board with Just the Connector...

-

FPC/FFC Connectors (XF2, XF3)

- If I Insert the Connector in a Locked State...

- If the Routing of the FPC Is Poor...

- If the Slider Is Held Down Incorrectly...

-

MIL Connectors (XG4, XG5)

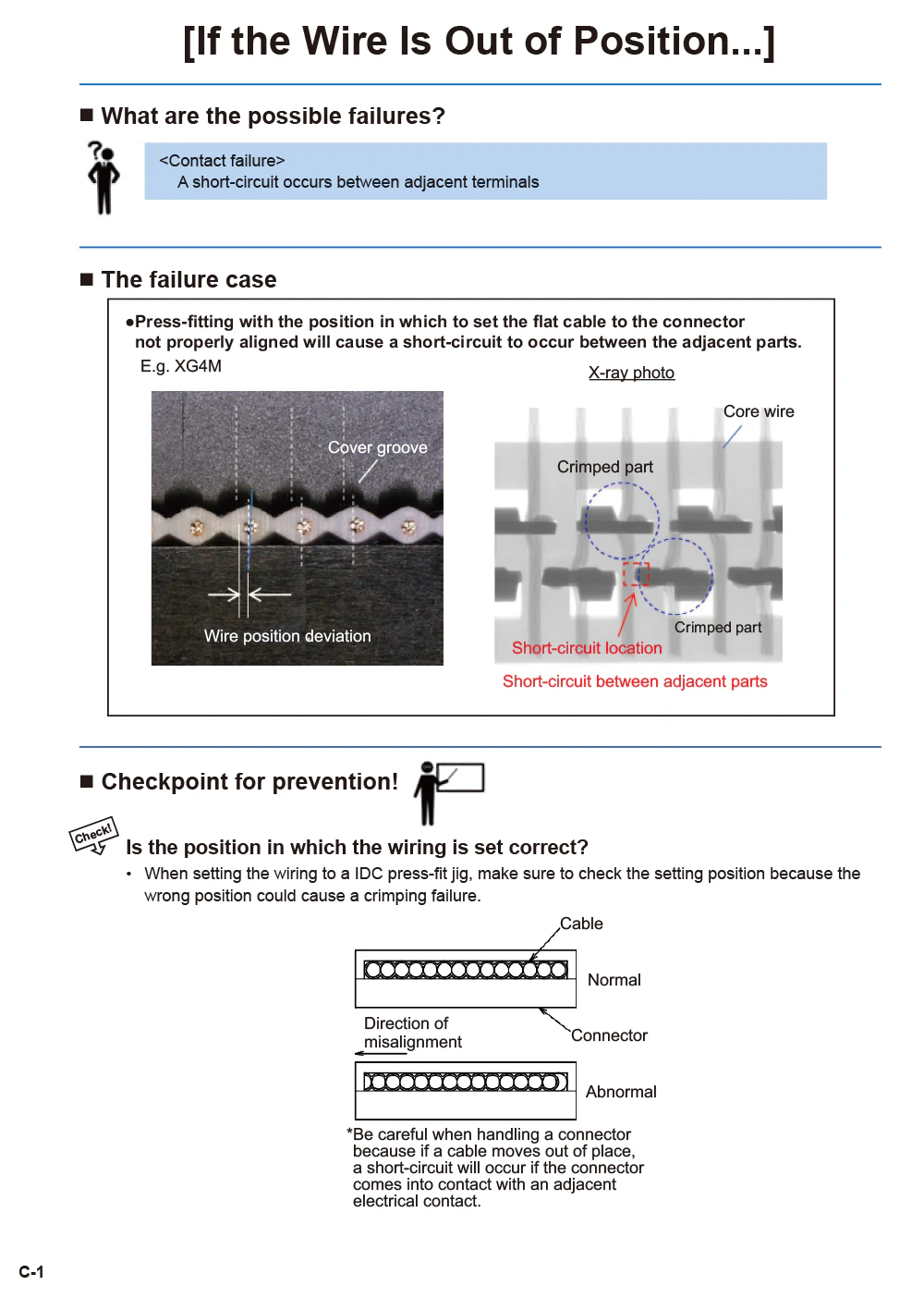

- If the Wire Is Out of Position...

- If I Crimp at an Angle...

- If I Apply an Excessive External Force...

- If I Mistake the Insertion Direction...

- If I Solder in a Half-Locked State...

-

Easy-Wire Connector (e-CON) (XN2)

- If the Wire Twisting Is Insufficient...

- If I Mistake the Wire Specifications...

-

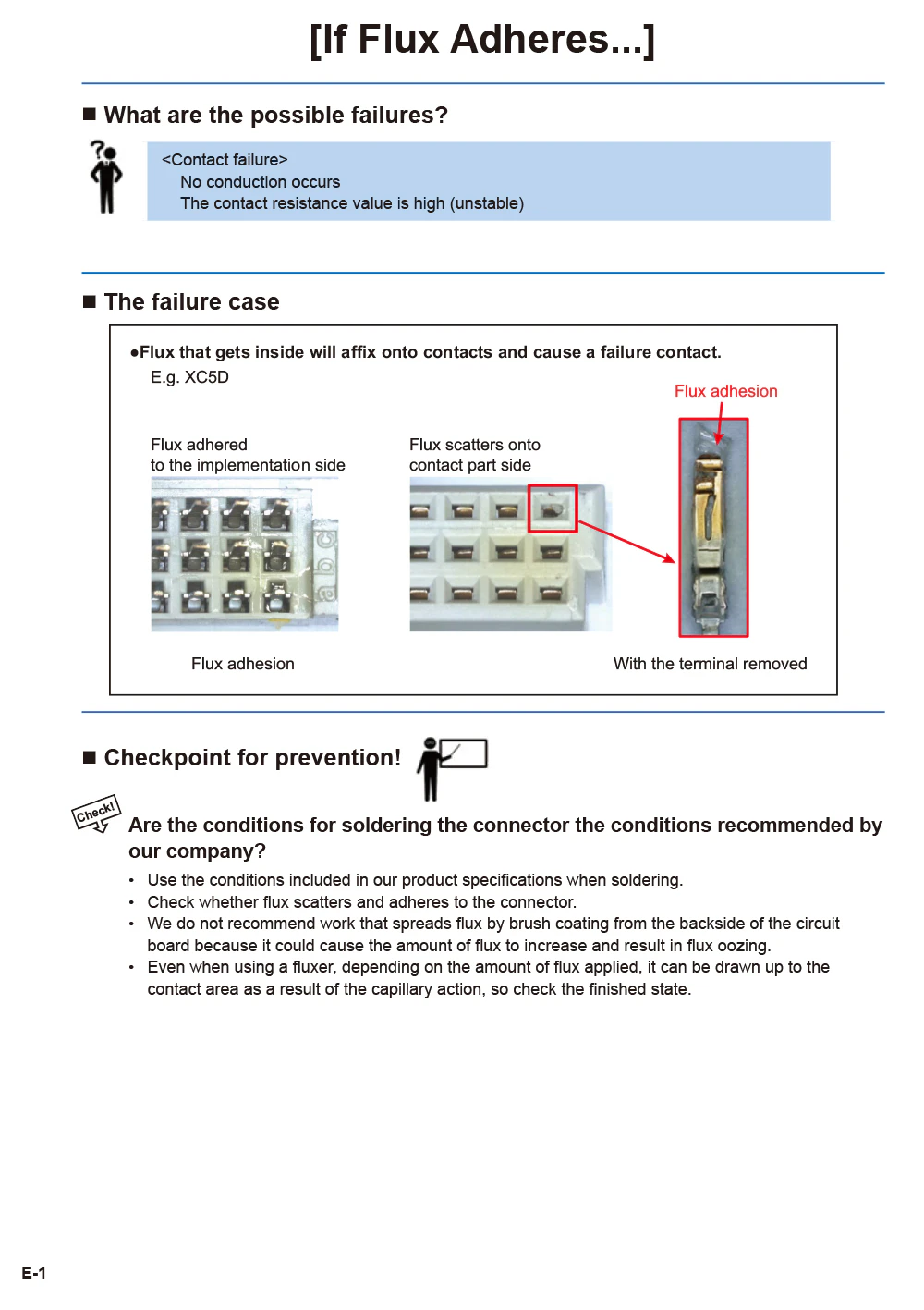

DIN Connectors (XC5, XC8)

- If Flux Adheres...

- If I Mistake the Tool Settings...

-

Interface Connectors (XM2, XM3)

- If I Process the Shield Braid Incorrectly...

- If the Screw Is Slanted...

-

Reference Materials

- Soldering Procedure

Optical Sensor

Click to read contents

Contents

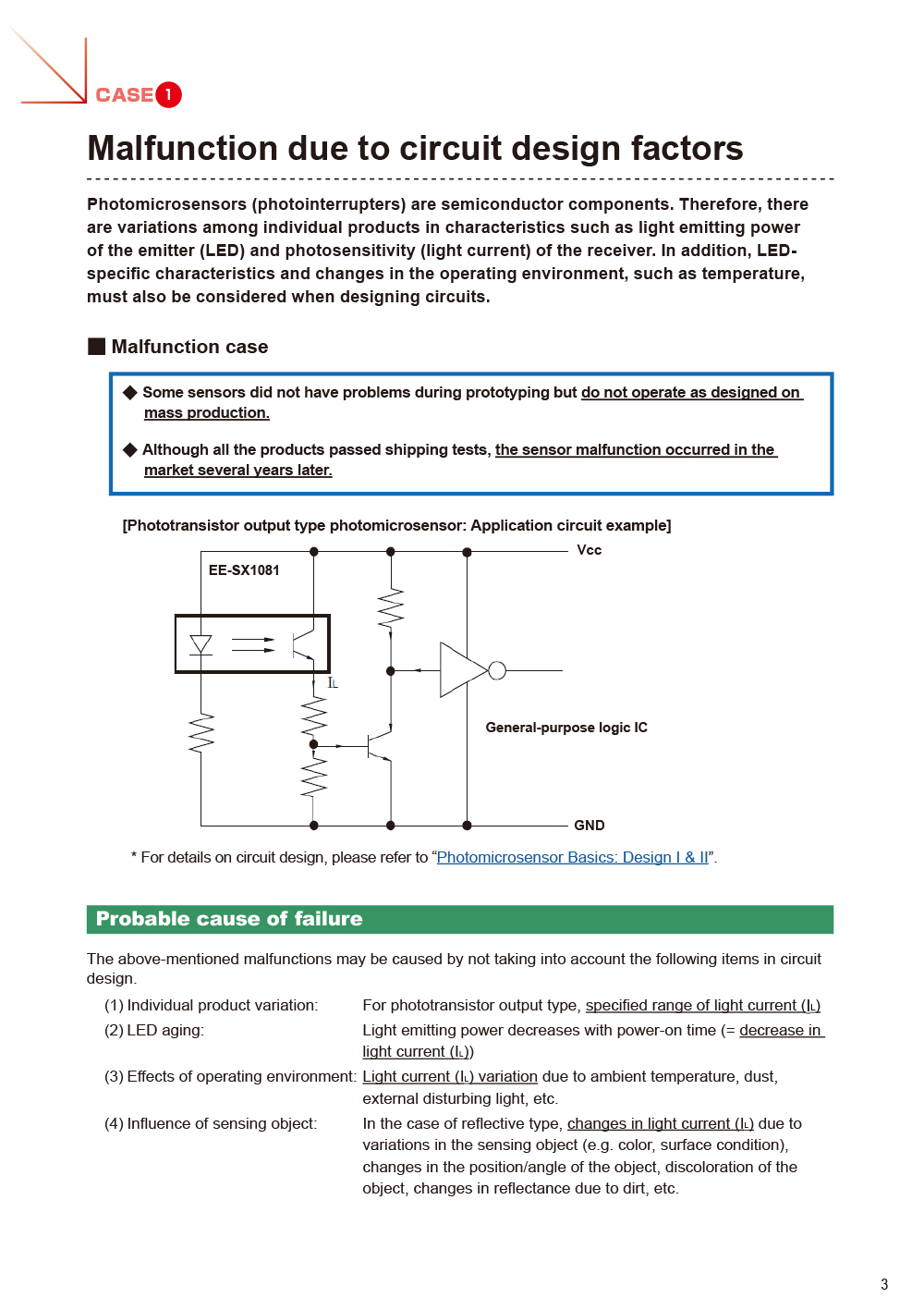

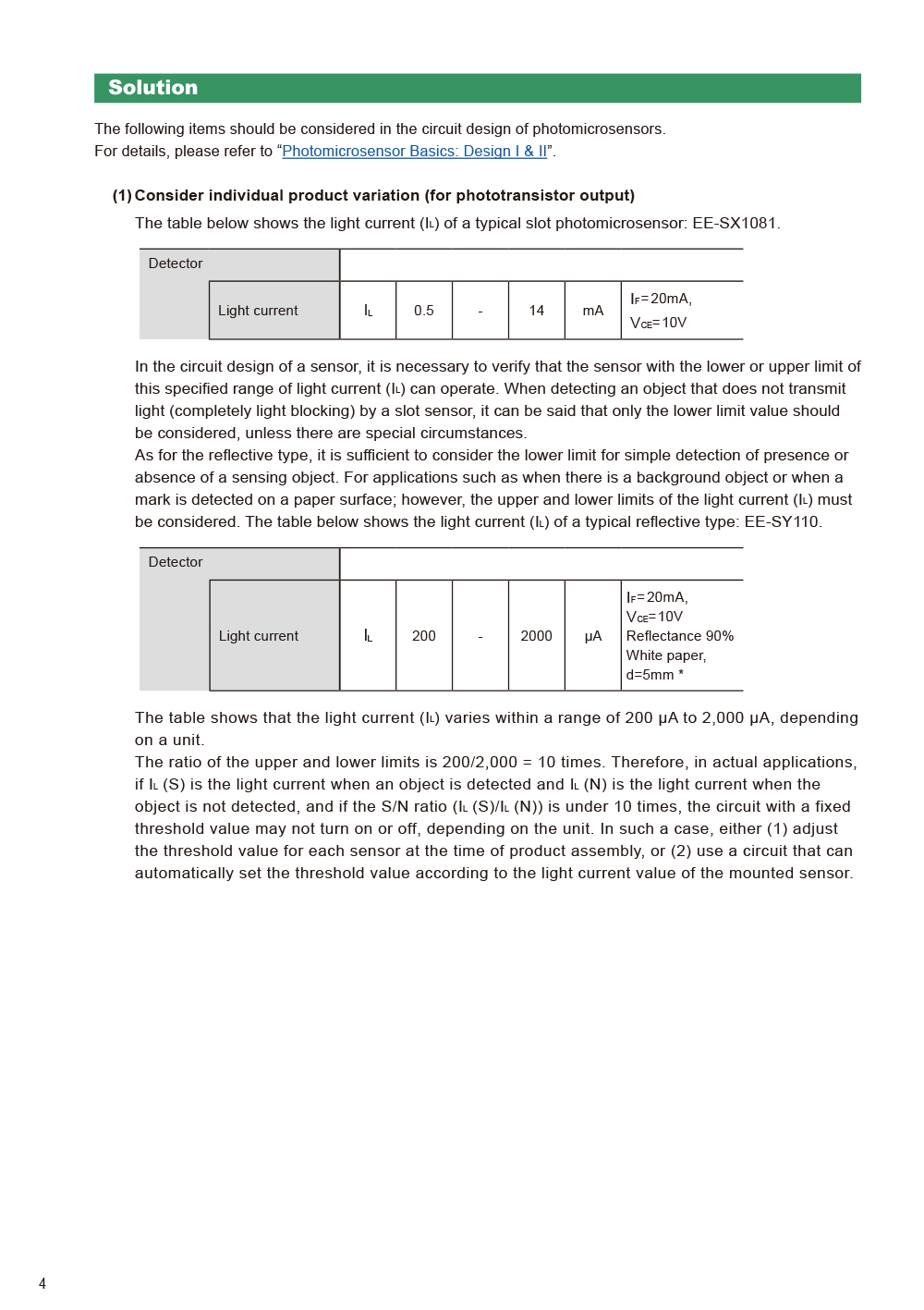

- CASE1 Malfunction due to circuit design factors

(Photomicrosensor) - CASE2 Malfunction due to LED open-circuit failure

(Photomicrosensor) - CASE3 Malfunction due to photo IC chip circuit breakage

(Photomicrosensor) - CASE4 Malfunction due to external disturbing light

(Photomicrosensor) - CASE5 Cracks or fractures in sensor case due to physical deterioration

(Photomicrosensor) - CASE6 Element disconnection due to overheating stress

(Photomicrosensor) - CASE7 Conductive error due to discoloration of lead terminals

(Photomicrosensor) - CASE8 Malfunction due to mutual interference

(Light convergent/diffuse reflective) - CASE9 Malfunction due to transparent cover

(Light convergent/diffuse reflective) - CASE10 Malfunction due to tilted shiny object

(Light convergent reflective)