Photomicrosensor

Application Guide ~Solution proposal for user’s challenges~

Summary

A built-in type Photomicrosensor, also known as a photointerrupter, is a compact optical sensor that senses objects or object positions. The best fit sensors to your applications can be chosen from a wide variety of available options.

Photomicrosensors (photointerrupters) are commonly used for object presence and absence detection, disk rotation counting, positioning of moving objects and rotating direction detection. In order to effectively use a Photomicrosensor, this Application Guide explains the principles, the types and the differences in usage of Photomicrosensors, and introduces actual application cases in detail.

What is a Photomicrosensor (photointerrupter)?

A Photomicrosensor (photointerrupter) is a compact optical sensor that senses objects or object positions with an optical beam. Photomicrosensors are used in consumer equipment (e.g. multifunction printers, IP cameras, robotic cleaners) and commercial devices (e.g. ATMs, copy machines, amusement machines, smart gas meters, machines for pharmaceutical products), which requires high reliability.

For more details, see “Fundamentals of Photomicrosensors”

Types of Photomicrosensors (photointerrupters)

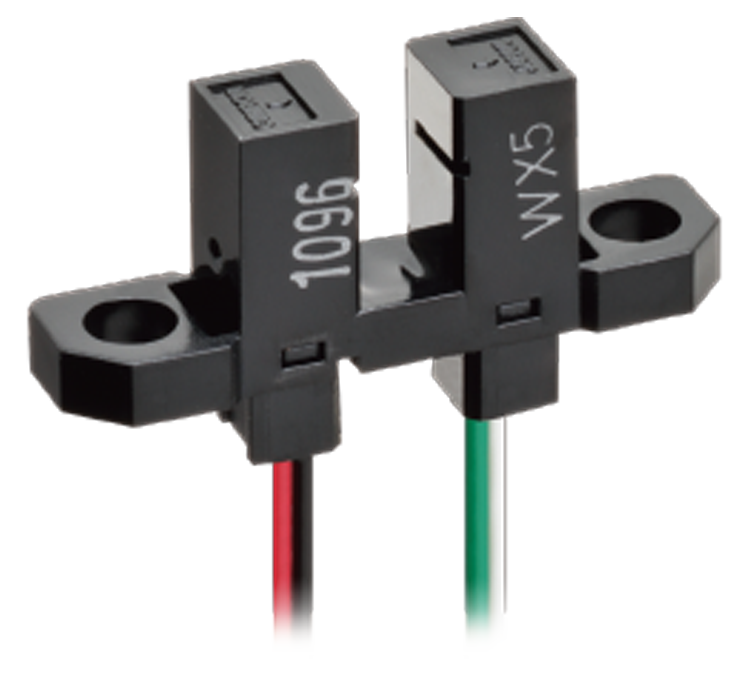

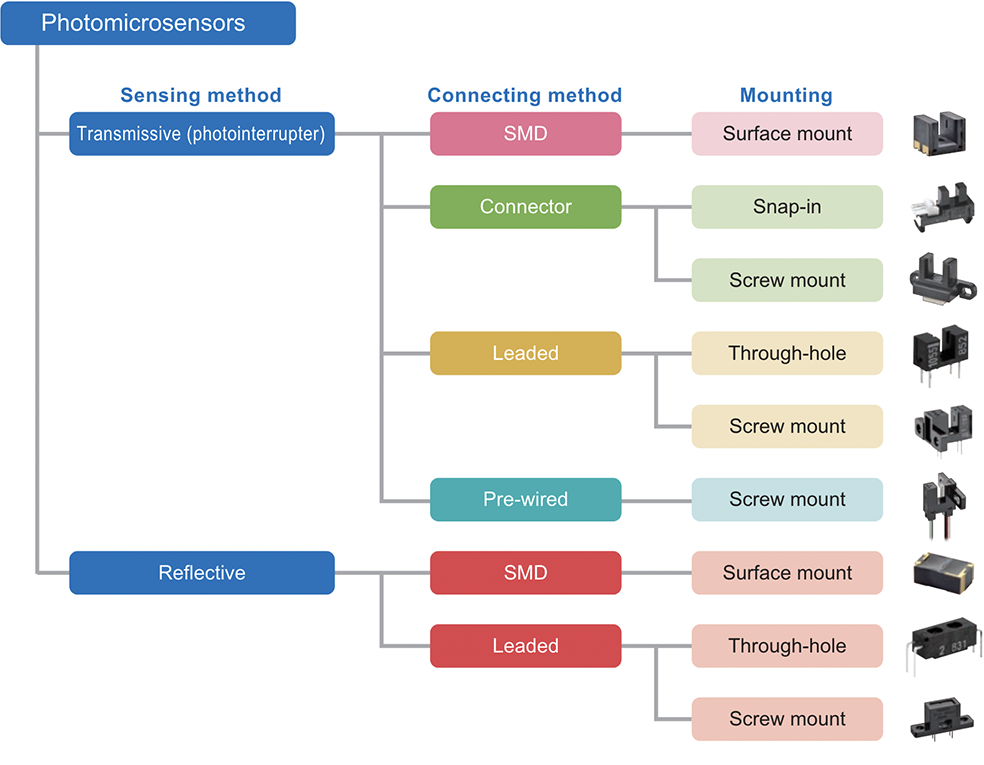

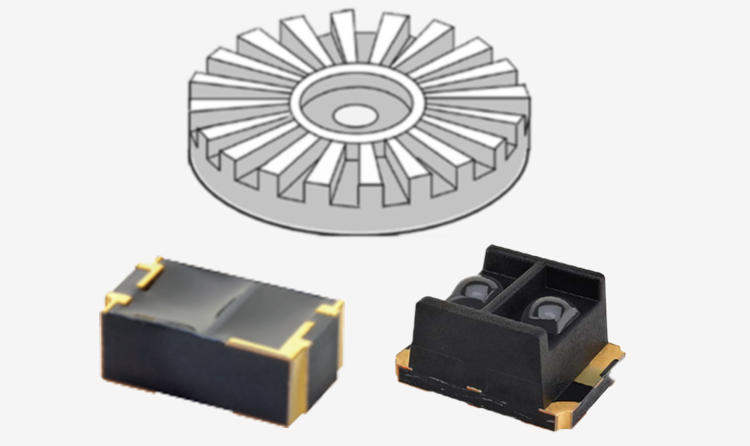

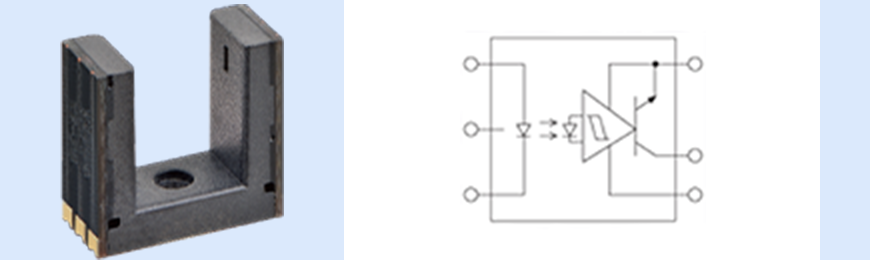

A Photomicrosensor (photointerrupter) is categorized into 2 main types. One is a transmissive (slot) type, the other is a reflective type. The illustration below is a general example of the connection/mounting method of different Photomicrosensors. PCB mounting is the most popular method of sensor attachment. Surface mount (SMD) is effective for downsizing and allows fewer man-hours of assembly. Pre-wired, or connector style is convenient for wiring and maintenance, and is ideal for detecting an object placed far from the main PCB. Omron advises users to choose a sensor that best matches the mechanical structure of the target device/equipment.

- SMD

- Connector

- Lead

- Pre-Wired

- Connection / Mounting

![[General use example]SMD:Surface mount, Connector:Screw mounting/snap-in, *Connector with cable is available by separate order, Pre-wired:*Detachable connector provided., Leaded:Through-hole](/sites/default/files/2022-04/pms_type_01_en.png)

- SMD

- Surface mount

- Connector

- Screw mounting/snap-in

*Connector with cable is available by separate order

- Lead

- Through-hole

- Pre-Wired

- *Detachable connector provided.

Photomicrosensor Types & Classifications

Typical applications of Photomicrosensors (photointerrupters)

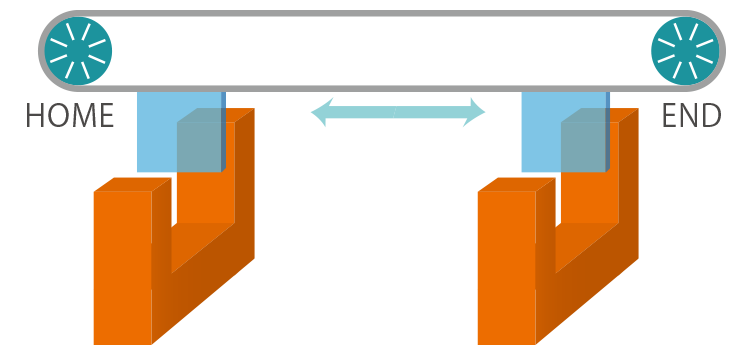

Photomicrosensors (photointerrupters) are commonly used for 1) Object presence and absence detection, 2) Disk rotation counting, 3) Positioning of moving objects and

4) Rotating direction detection (for encoder use).

Here are some examples of typical applications using each of the two types of Photomicrosensors: transmissive (slot) type and reflective type.

| Application examples | Transmissive (Slot) Type | Reflective Type |

|---|---|---|

| Presence/absence detection |

Typical application:

* Detects the shielding plate added to the door/cover that blocks the light path. |

Typical application: * Detects the object without a shielding plate. |

| Count |

Typical application:

* Photo-IC output type is effective for high-speed rotation. |

Typical application:

* Compact and suitable for space-saving designs |

| Position detection (Origin point detection) |

Typical application:

* Origin point detection for rotating disk (rotary motion) |

Typical application: * Detects the object without a shielding plate. |

| Rotating direction detection |

Typical application:

* Transmissive type is commonly used for this type of application as high accuracy is required. |

You can see all by scrolling horizontally.

The difference in usage between a Photomicrosensor (photointerrupter) and a basic switch?

A basic switch is made of open and closed contacts whereas a Photomicrosensor (photointerrupter) is non-contact switching using an optical beam. A basic switch is available for AC and DC supplies. Since a basic switch does not emit LED, it is ideally suited for applications that require low current consumption such as battery-powered equipment. A Photomicrosensor is superior in durability, sensing position accuracy and response speed.

Photomicrosensor

- Durability

There is no limit on the number of switching actions.

Degradation of the light emitting diode (LED) takes place over time. - Sensing position accuracy

± 0.25 mm or below (= slit width)

*Repeated sensing position characteristics: 0.01 mm - Response speed

3,000 times / sec. (photo-IC output type)

- Voltage specification

DC 4.5 - 16 V (photo-IC output type)

- Clicking sensation

No

- Effects of external light interference

Yes (use something like a cover to avoid exposure to ambient light)

- Applications

Non-contact switching using light eliminates the contact deterioration problem caused by wear and corrosion.

A suitable candidate for applications that require frequent switching and high reliability.

Also superior in detecting minute objects with excellent response speed and sensing position accuracy ideally suited for applications such as copy machines, ATMs (paper detection and sensing papers passing through) and cameras and robots (gear rotation detection).

Basic switch

- Durability

Mechanical durability: More than 1 million times

Electrical durability: 1 to 100,000 times or more

- Sensing position accuracy

± 0.3 - 1.5 mm or below

- Response speed

100 - 200 times / min.

- Voltage specification

DC 30 V or below

AC 125 V - 250 V or below - Clicking sensation

Yes

- Effects of external light interference

No

- Applications

A simple contact switching mechanism to open and close a circuit. Available for AC and DC supplies. Not affected by light, magnetic or noise interference.

Suitable for applications that require low current consumption such as in battery powered equipment and for devices in which a clicking sensation plays an important role (e.g. mouse, joystick). Some models are suitable for high-capacity load switching applications.

*These differences do not necessarily apply to all the available product models. Be sure to check the specification datasheet for details of each product model.

A Photomicrosensor, with its non-contact switching technique, has the advantage of high reliability, eliminating the contact deterioration problem caused by wear and corrosion.

For example, for a switch within machine internals that may remain closed for an extended period of time, the contacts may deteriorate from oxidation and sulphuration due to the surrounding atmosphere, ultimately affecting the switching performance. Using the Photomicrosensor for such applications is ideal without worrying about contact deterioration.

The difference in usage between transmissive (slot) and reflective Photomicrosensors (photointerrupters)

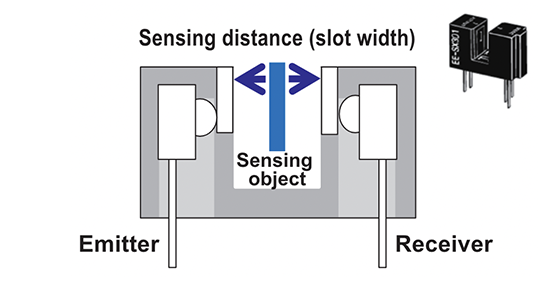

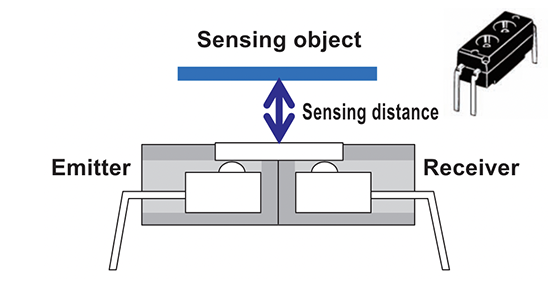

Below are the structural differences and principles of transmissive (slot type) and reflective Photomicrosensors.

Transmissive (Photointerrupter)

Objects are sensed as the light beam is blocked by an object.

- ・Stable sensing of opaque objects

- ・High accuracy in positioning

Reflective (Photoreflector)

Objects are sensed by the reflected light on the object.

A transmissive(slot) Photomicrosensor(photointerrupter) detects objects by passing the target object through the emitted light beam from the aperture. This is ideal for applications of small object detection or accurate position sensing. A reflective Photomicrosensor detects the presence and absence of objects but also detects marked objects. This type is effective for realizing a low-profile design of a device or piece of equipment.

The transmissive (slot type) Photomicrosensor provides stable detection regardless of the object’s surface condition, position or angle. It is recommended to first check if the design of your device/equipment can apply the transmissive Photomicrosensor (for sensing opaque objects). Here are the advantages and disadvantages of the transmissive (slot type) and reflective Photomicrosensors:

|

Photomicrosensor |

Transmissive (Slot Type)  |

Reflective  |

|---|---|---|

| Advantage |

|

|

| Disadvantage |

|

|

You can see all by scrolling horizontally.

The difference in usage between a phototransistor output and Phot IC output for Photomicrosensors (photointerrupters)

With a phototransistor output, the threshold level to turn the sensor on or off is adjusted using an external circuit, whereas with photo IC output, the threshold level is fixed at an internal circuit board. Phototransistor outputs enable users to set an optimum threshold level according to the application. Photo IC output is ideal for applications requiring a fast response time.

The following table explains the differences between phototransistor output and photo IC output. Please use this as a guide when selecting your sensor and check the specification datasheet for product details.

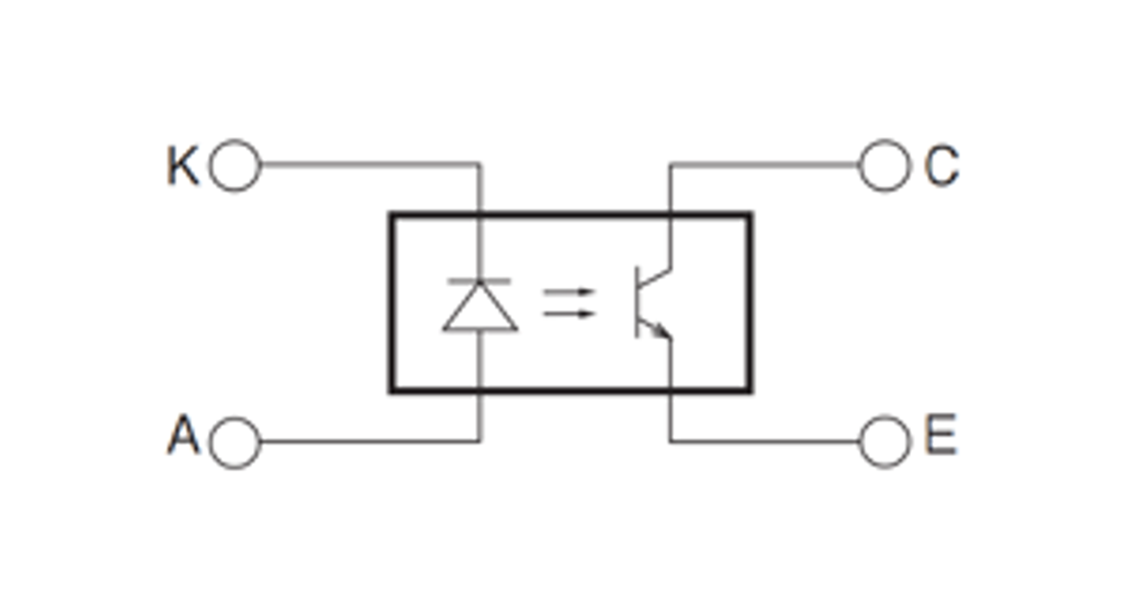

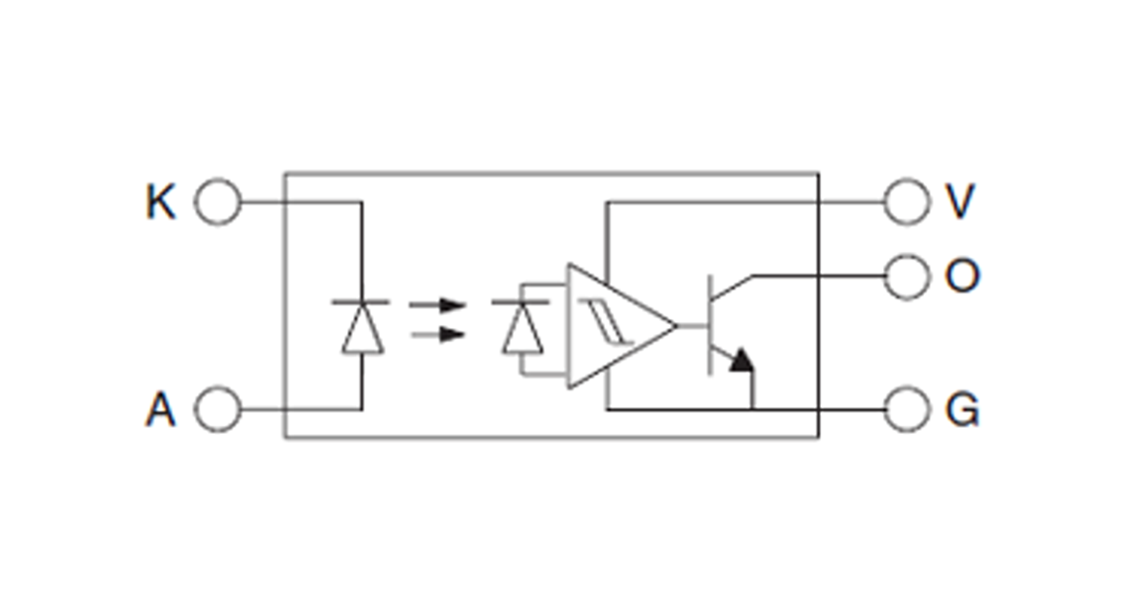

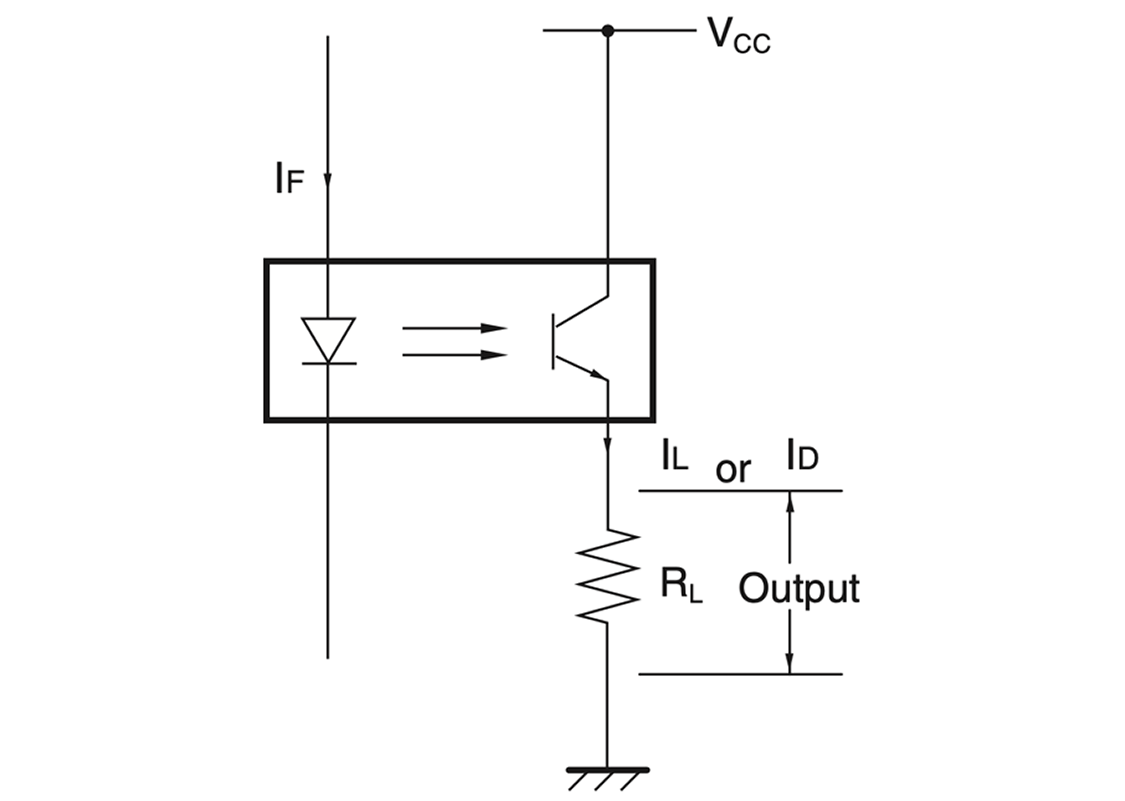

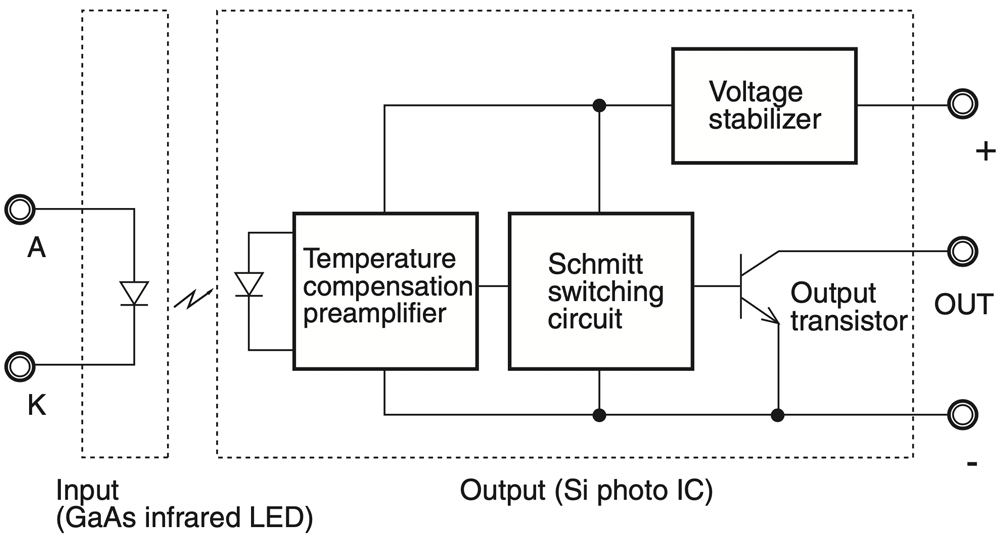

| Photomicrosensor | Phototransistor output | Photo IC output |

|---|---|---|

| Internal circuit |  |

|

| Circuit configuration |

The presence or absence of the sensing object is determined by comparing the light current IL (A) and IL (B) flowing through the phototransistor with (A) and without (B) the sensing object.

The threshold for judgment is set on the external circuit. |

Shown below is the circuit configurations of photo IC output type.

Thus the threshold for output ON/OFF is fixed. |

| Differentiation |

When the ratio of the light current IL (A) to the light current IL (B) is not sufficiently large in actual equipment, setting the optimum threshold value is the key to stable detection. In such a case, select the phototransistor output type for which the threshold can be set. |

When the ratio of the light current IL (A) to the light current IL (B) is sufficiently large in actual equipment, photo IC type is recommended to make circuit design easier. It is also ideal for applications requiring high-speed response (3 kHz min.), such as the detection of the number of revolutions of a disk with slits.  |

You can see all by scrolling horizontally.