MEMS Flow Sensors Selection

Feature of MEMS Flow Sensors

Realizing a highly accurate flow measurement, sensing even a single flap of a butterfly’s wings

Omron’s MEMS flow sensor accurately detects minute airflow so much as a single flap of a butterfly’s wings.

A gas flow sensor capable of “measuring mass flow” independent of temperature and pressure.

Mass Flow Measurement

-

QThere are two balloons; each having different volumes. But these balloons have the same mass. Why is that?

- A

The volume increases/decreases according to the pressure and temperature changes. The mass, on the other hand, remains constant regardless of the environmental changes. The mass flow measurement allows measurement performance that is not affected by the changes in the environment.

-

QWhy is mass flow measurement required?

- A

An accurate measurement of the flow is required especially for combustion control. Omron’s flow sensor enables measuring the gas flow based on the mass flow measurement.

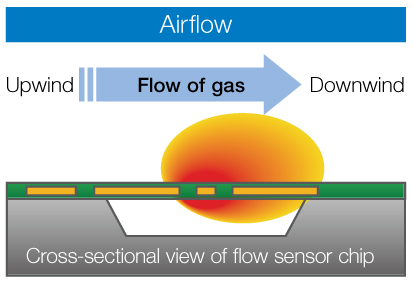

Principles of MEMS Flow Sensor Measurement

D6F Series

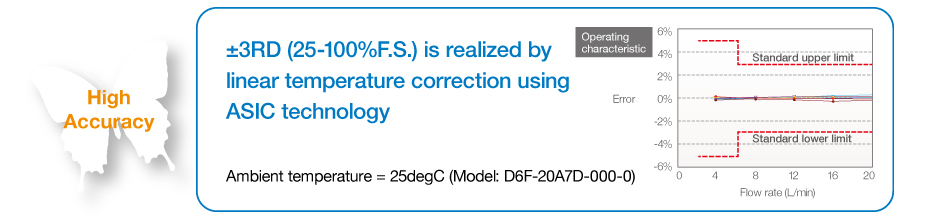

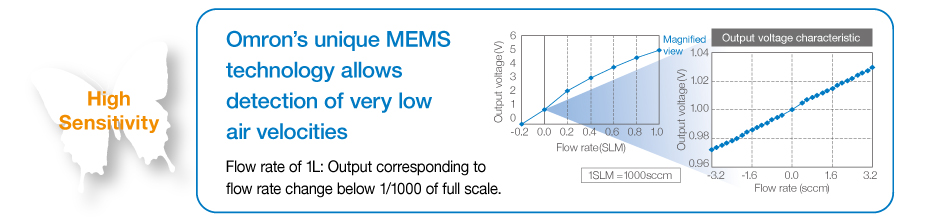

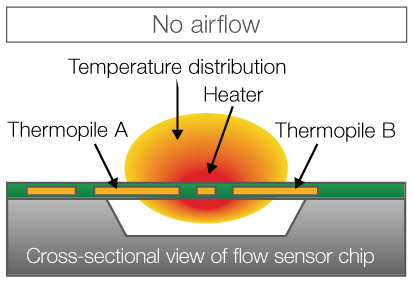

During the absence of airflow, the temperature distribution around the heater is symmetrical. When there is airflow, the temperature of the upwind side cools down and the temperature of the downwind side warms up, disrupting the symmetry of the temperature distribution.

By detecting this temperature difference appearing as a difference in the electromotive forces developed by the thermopiles, it allows the mass flow rate and mass flow velocity to be measured without the influence of temperature and pressure. Since the thermopile generates the thermo-electromotive force, the power consumption is much lower than when using the resistivity method.

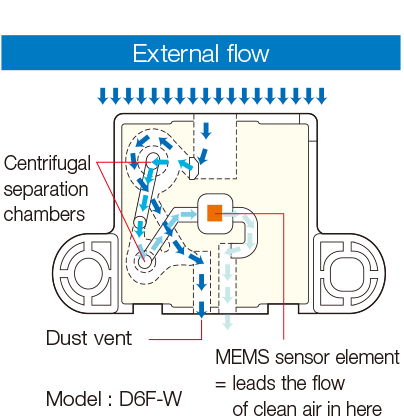

MEMS Air & Gas Flow Sensors are Highly Resistant to Dust

Built-in Dust Segregation System (cyclonic)

D6F-W/-V/-P

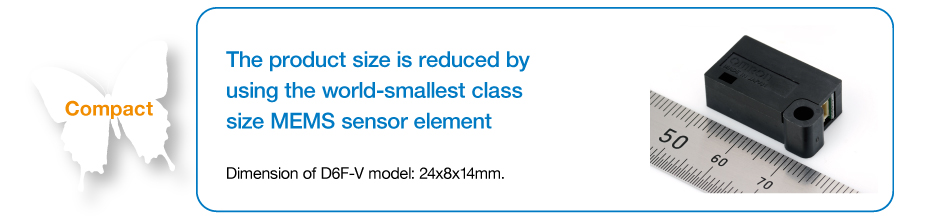

The sensor can be placed anywhere thanks to its dust-resistant structure. Omron’s unique design of 3D flow path provides a high level of reliability by separating dust particles to reduce its effect on the sensor chip. Additionally, Omron succeeded in reducing the sensor size, allowing it to be used in wider range of applications.

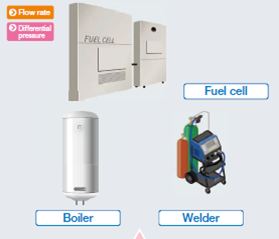

Application Examples

Combustion

For optimal control of the amount of gas

by measuring the mass flow rate.

Optimizing combustion efficiency.

HVAC

For feedback control of air conditioning

by measuring the amount of air and amount of ventilation.

Controlling the amount of air at the required level and monitoring the amount of ventilation.

Measurement

For optimal control of pumps by measuring the flow rate.

For management of positive pressure and negative pressure by measuring the differential pressure.

Accurately detecting gas concentrations.

Monitoring the positive/negative pressure in a room.

Clogging Detection

For monitoring the flow of the cooling air to optimize the cooling efficiency and avoid malfunctions.

Quiet, low maintenance cost.

Contact us

Contact us