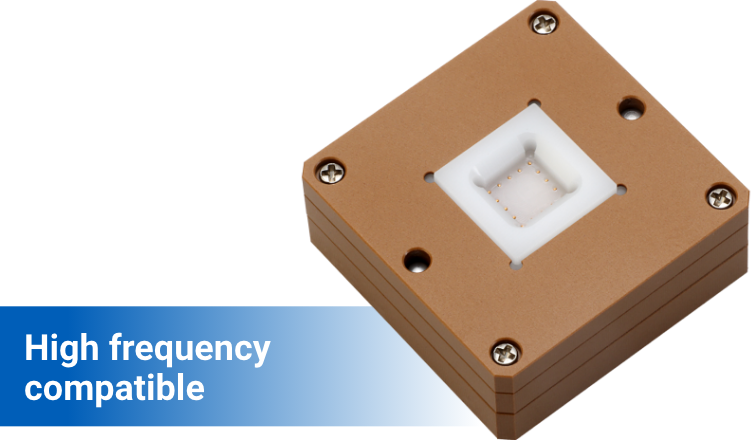

High frequency is one of the most important technologies in the mobile communication field. Electronic equipment all around us such as wireless LANs, cellular phones, and GPS are full of high-frequency circuits. Naturally, the equipment used to inspect them is also required to have excellent high-frequency characteristics. OMRON’s high frequency compatible sockets can handle up to 43.5GHz frequency band.

We propose a path length that has sufficient stroke length.

| Item | Specification |

|---|---|

| Pitch | 0.175/0.3/0.35/0.4/0.5mm or more |

| Stroke | 0.2mm or more |

| Contact resistance | 100mΩ or less |

| RF | 50GHz or less |

| Plating | Au |

*Specifications are for reference only and may vary depending on the customized product.

We can custom design each pin and socket to suit the actual customer application. Please contact us for details.

Handling high frequencies up to 43.5GHz

Handling high frequencies up to 43.5GHz

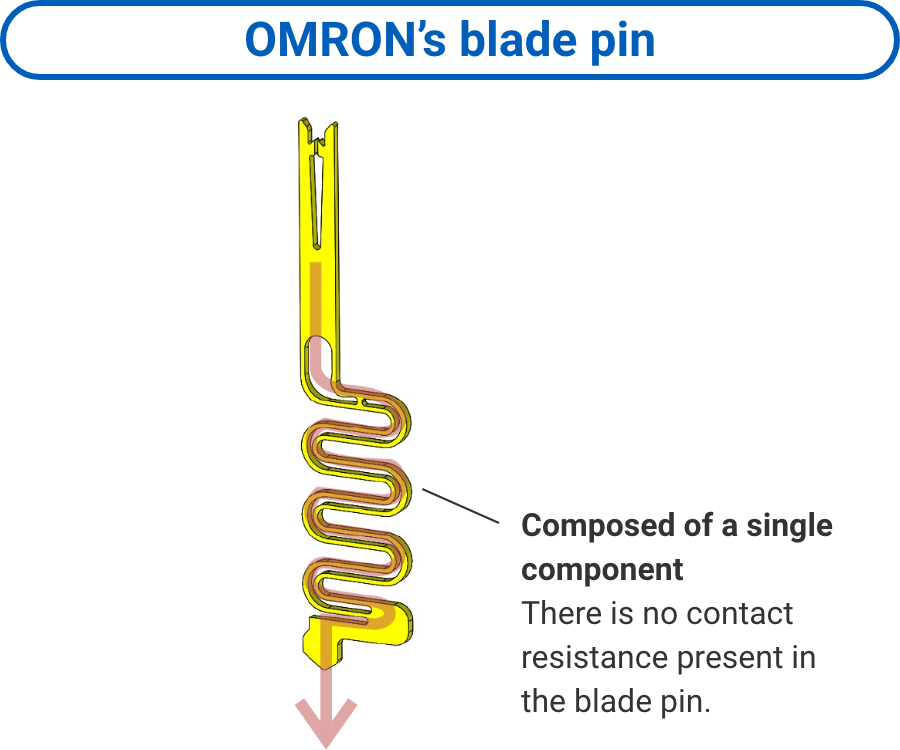

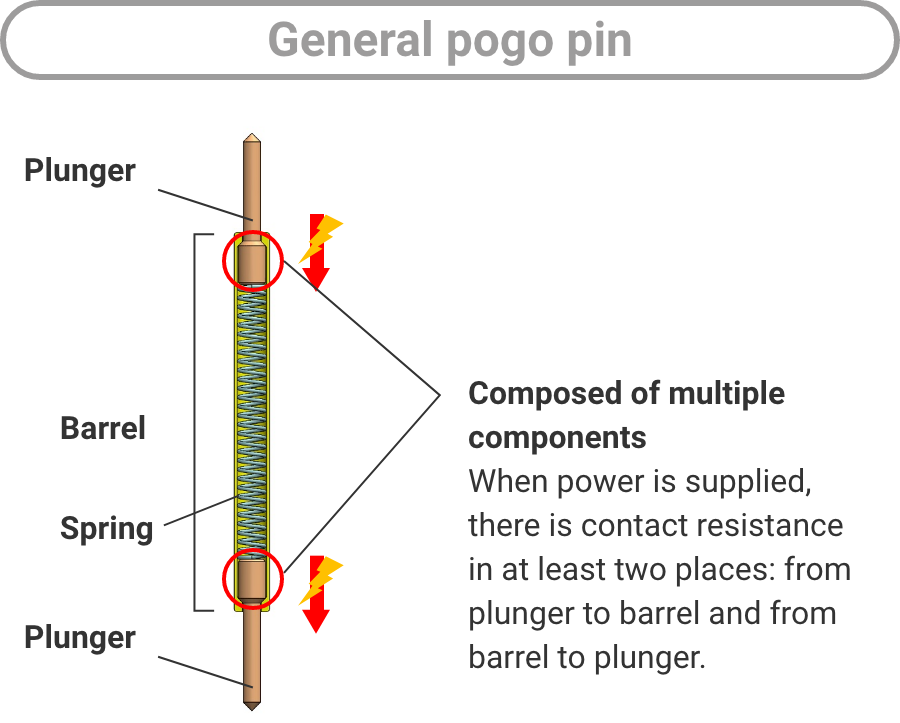

OMRON’s high-frequency compatible sockets can handle up to 43.5GHz frequency band. The key to enhancing high-frequency characteristics is to eliminate contact resistance as much as possible. Since general pogo pins are composed of multiple parts, they tend to have high internal resistance and poor high-frequency characteristics. However, OMRON’s high-frequency pins can be manufactured in a single component using a processing method unique to the EFC process technology. Excellent high-frequency characteristics can be achieved because there is no contact resistance between the contacting parts of the components.

High durability and reduced maintenance

High durability and reduced maintenance

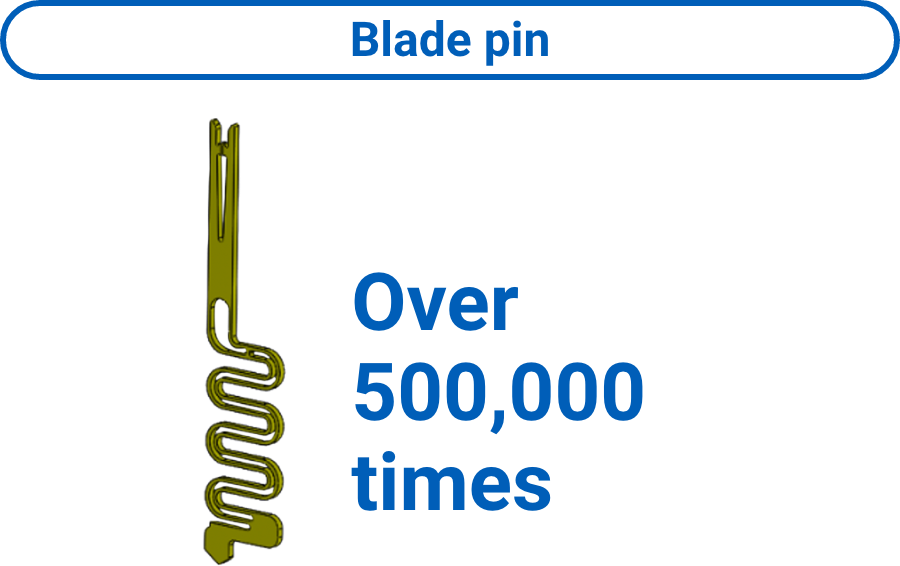

Custom design recommendations that best suit the customer’s application and OMRON’s original material blend* make our sockets more than five times more durable than pogo-pin sockets. This greatly reduces the frequency of testing socket replacement at the inspection site, contributing to improved production efficiency.

*Patent No. 5077479

*An example of B-to-B connector inspection