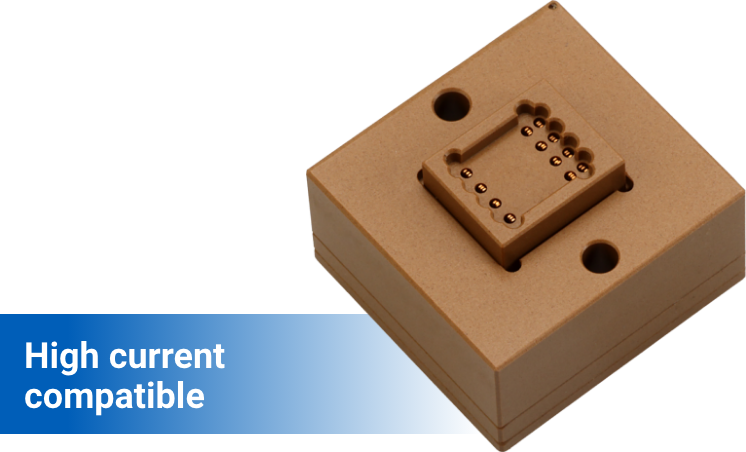

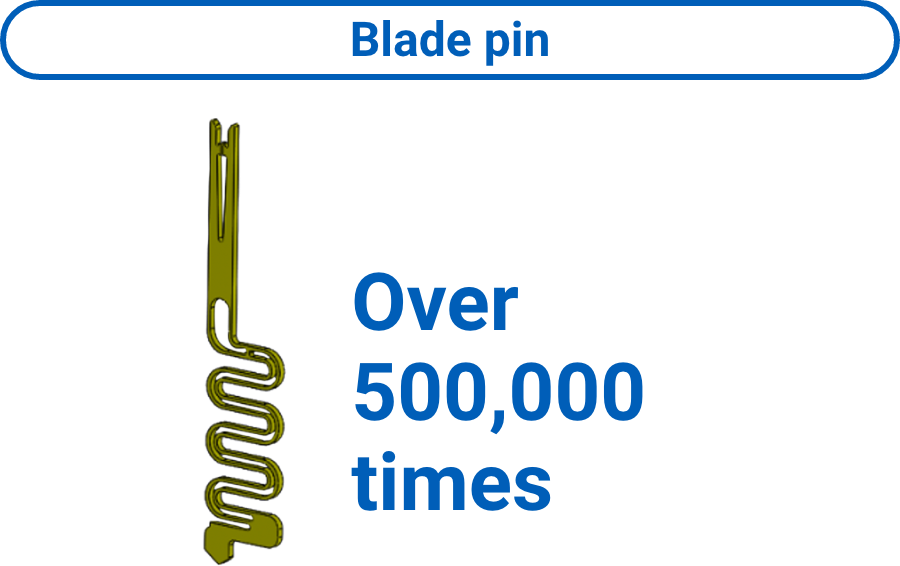

The need for high-capacity equipment is steadily increasing, and the equipment that inspects the equipment is also required to handle high capacities. OMRON’s high-current compatible sockets have a long mechanical durability of 500,000 times or more and can handle high currents of 2.5A DC or higher. A wide range of variations are available to expand the scope of customer inspections.

| Item | Specification |

|---|---|

| Pitch | 0.175/0.3/0.35/0.4/0.5mm or more |

| Stroke | 0.5mm or more |

| Contact resistance | 50mΩ or less |

| Rated current | 2.5A DC or more |

| Plating | Au |

*Specifications are for reference only and may vary depending on the customized product.

We can custom design each pin and socket to suit the actual customer application. Please contact us for details.

Bundle structure can handle up to 10A DC

Bundle structure can handle up to 10A DC

![[Cross-sectional view] Bundle structure. Bundling multiple pins (3 to 4 pins) together realizes large currents. High current pin (*Customizable)](/us-en/sites/components.omron.com.us/files/2023-05/product-efc03_02_01_en.png)

OMRON’s high-current type can handle up to 2.5A DC using a single pin, and up to 10A DC by adopting a bundle structure with multiple pins connected. It can be used for inspection of power semiconductors such as QFN (quad flat non-leaded) packages.

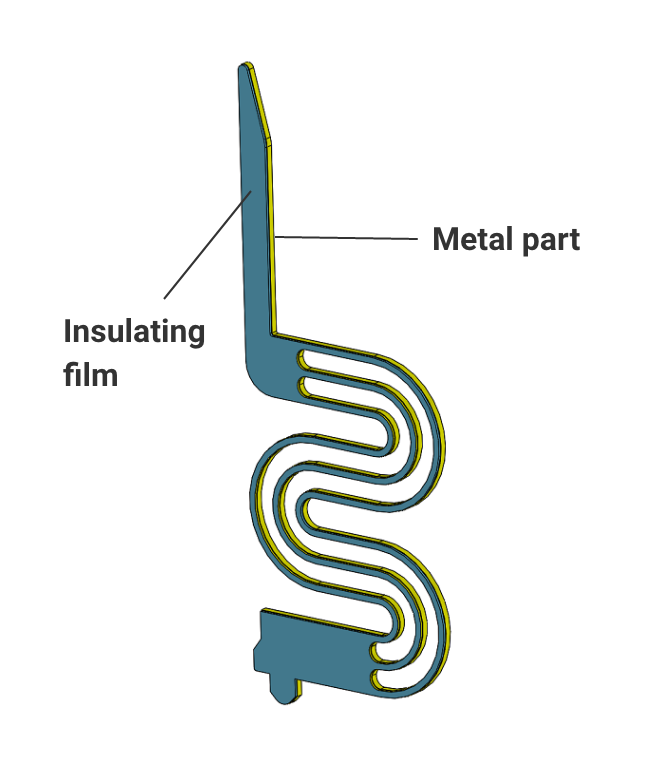

In order to achieve a large current while ensuring sufficient spring property, the high-current type uses a multiple-spring structure where multiple springs are connected using a manufacturing method unique to the EFC process technology. Larger and thicker pins can handle larger current, but this will result in poor spring property, leading to reduced contact accuracy and durability. The multiple-spring structure provides the same conduction area as a single-spring, and the design of providing space allows for flexible movement inside the pin while accommodating large currents.

![[Multiple-spring structure] The multiple-spring structure is realized by a manufacturing method unique to the EFC process technology. Sufficient spring property is maintained while keeping large current characteristics.](/us-en/sites/components.omron.com.us/files/2023-05/product-efc03_02_02_en.png)

![[Single-spring structure] Brittle and fragile because of the movement of wide and hard pins. Poor spring property reduces contact accuracy.](/us-en/sites/components.omron.com.us/files/2023-05/product-efc03_02_03_en.png)

Handling ultra-high current range under low duty ratio (actual value)

Handling ultra-high current range under low duty ratio (actual value)

OMRON conducts duty ratio tests on high current sockets to evaluate their performance. OMRON’s high-current type has the ability to handle even larger currents under a low duty ratio (when the current flow time is short). Semiconductor testing is only used to check for continuity and is not used in such a way that a large current is applied for a long period of time. Under low duty ratio, OMRON’s high-current type can also be used to inspect power semiconductors with specifications of several tens of amperes, which is considered to be in the ultra-high current range in the semiconductor industry. Please consider adopting OMRON’s high-current type.

![Duty ratio[%] / Current[A]](/us-en/sites/components.omron.com.us/files/2023-05/product-efc03_03_01.png)

*Actual values, not guaranteed values

Kelvin connection compatible

Kelvin connection compatible

High-density terminal arrangement with minimized insulation distance to

handle large currents

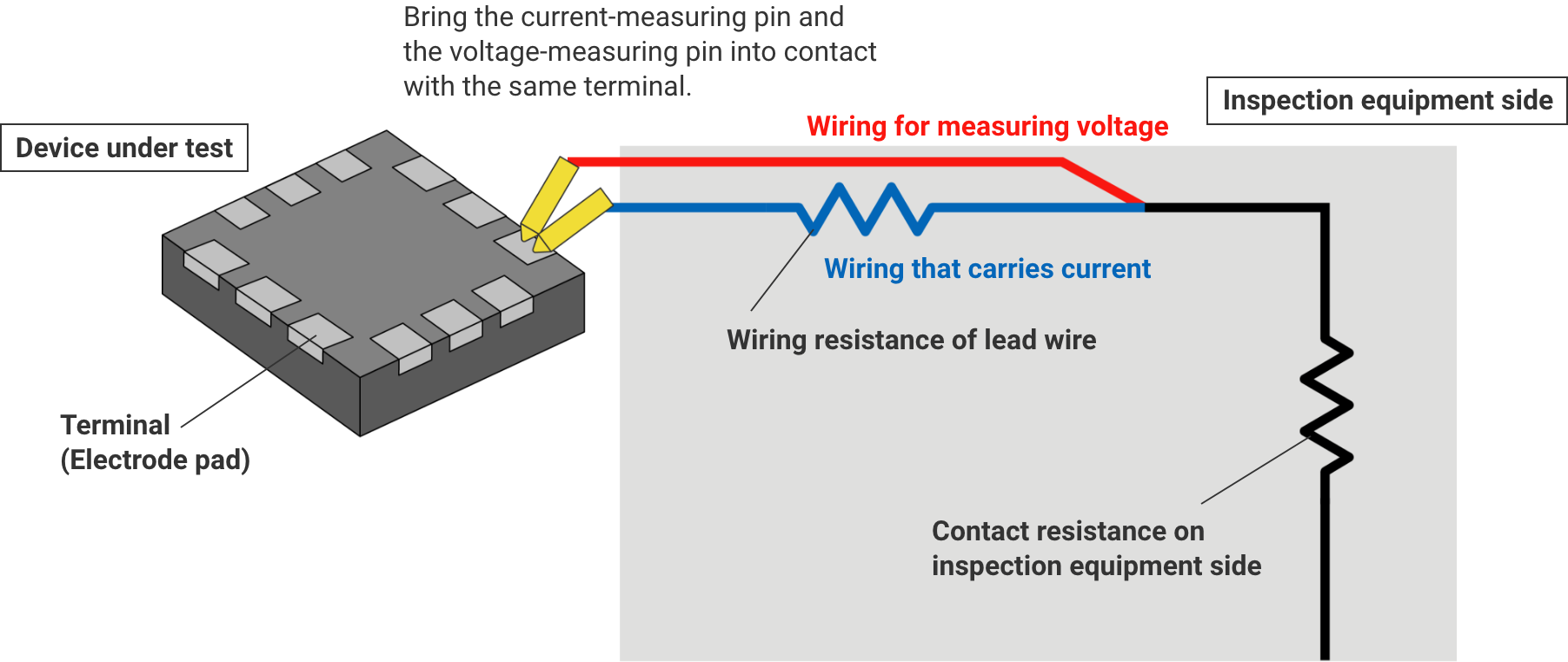

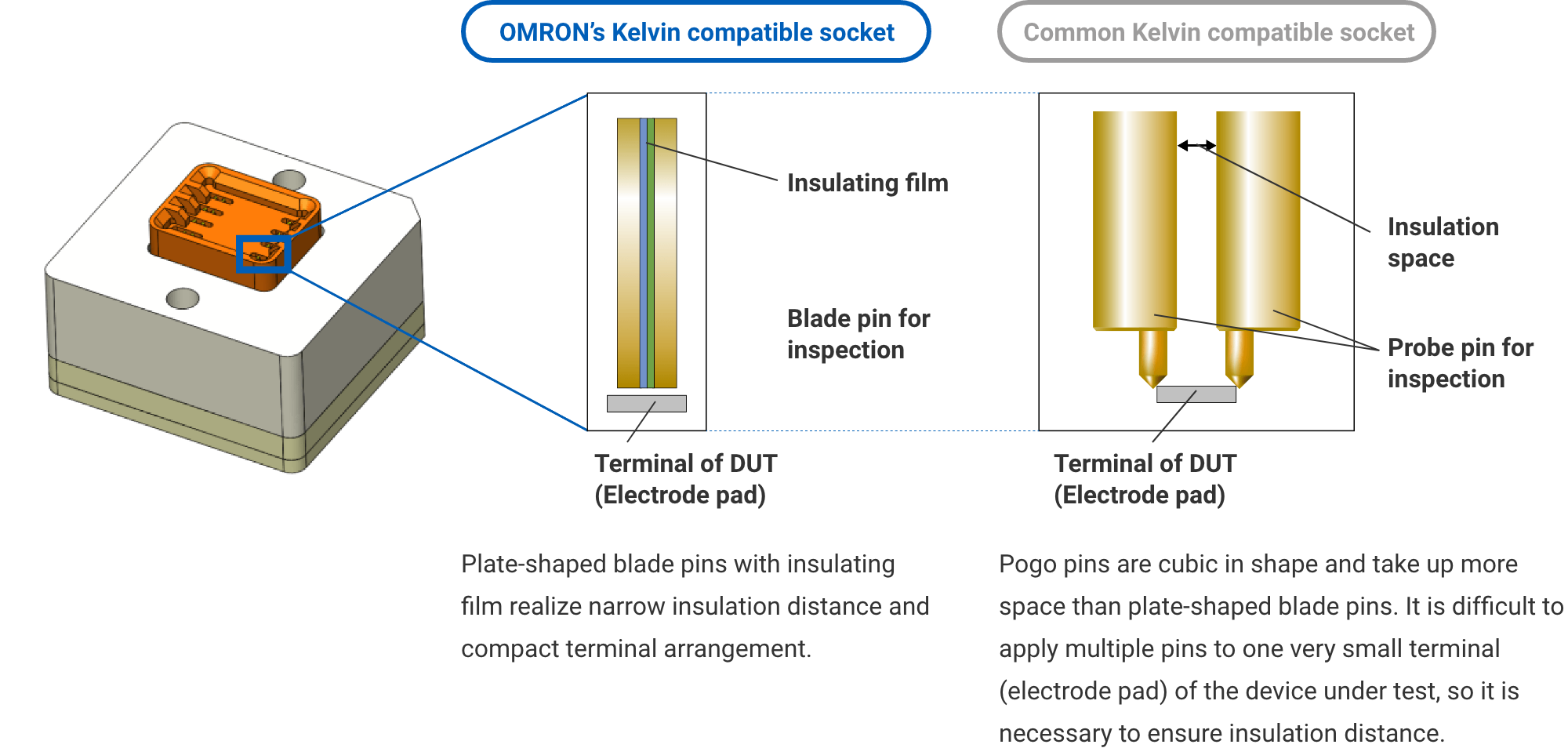

There are probably many customers who use Kelvin connection measurement (four-terminal measurement) for the inspection of power semiconductor products that handle large currents. The larger the current, the higher the contact resistance, and the more difficult it is to accurately measure the specifications of the device under test. The Kelvin connection separates the terminals for current measurement from those for voltage measurement, allowing accurate measurement of the resistance of the device under test without being affected by lead resistance or contact resistance.

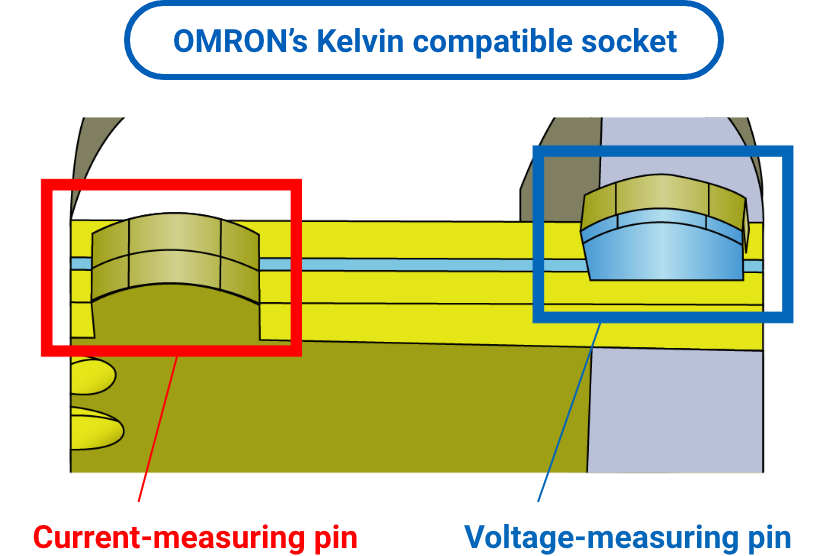

Since Kelvin measurement requires that the current-measuring pin and the voltage-measuring pin are in contact with the same terminal, it is important that both pins are properly insulated to ensure safe use. OMRON’s high-current compatible type also offers sockets with pins equipped with insulating films.

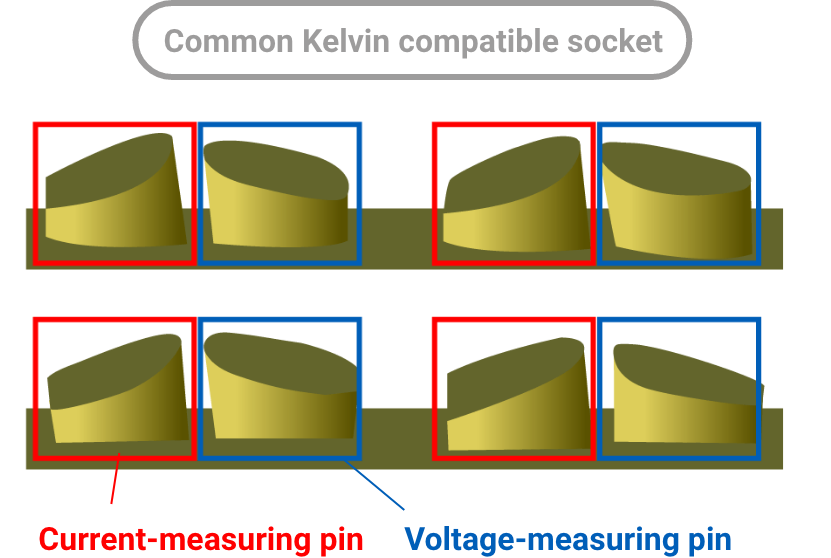

In general, as the number of pins available for measurement increases, it becomes possible for larger currents to be measured and inspected. Pogo pins are cubic in shape, so they require more mounting space than plate-shaped pins. This makes it difficult to press multiple pins against a very small terminal (electrode pad) for inspection.

In addition, the isolation distance must be secured to allow larger currents to flow. Therefore, with typical Kelvin compatible sockets, the challenge is how to apply multiple pins to a high-current, small-package device under test.

OMRON’s high temperature compatible type blade pins are plate-shaped and very slim. Since more test pins can be applied to one terminal (electrode pad), it is possible to handle larger currents than with common Kelvin compatible sockets. Furthermore, the blade pins have an insulating film, which allows space-saving design without taking up a large insulating space, even when used at high currents.

Conventional Kelvin compatible sockets require the current and voltage pins to be placed separately in some cases affects the design of the device under test and measurement equipment, such as the layout of terminals. However, OMRON’s Kelvin compatible sockets allow the current and voltage pins to be placed separately within the same bundle by simply flipping the pins. This can contribute to a reduction in the customer’s design and manufacturing man-hours.

High durability and reduced maintenance

High durability and reduced maintenance

Custom design recommendations that best suit the customer’s application and OMRON’s original material blend* make our sockets more than five times more durable than pogo-pin sockets. This greatly reduces the frequency of testing socket replacement at the inspection site, contributing to improved production efficiency.

**Patent No. 5077479

*An example of B-to-B connector inspection