Electroforming Microfabrication Technology

Technology that creates parts with unprecedentedly complex shapes

Features

Microfabricated Complex Shapes

Realizing high-aspect and complex shapes that cannot be realized by conventional machining

unique materials

In-house developed original materials with both conductivity and spring characteristics

Mass Productivity

Mass replication of microfabricated parts is enabled by electroforming process with little dimensional variation

Technology Details

Microfabricated Complex Shapes (High-precision Master Processing)

With high-precision machining, three-dimensional shapes with dimensional accuracy of tens of nm and surface roughness of Ra = 3 nm can be achieved on the master. Parts with complicated shapes are fabricated by replicating the shape of this master with electroforming.

Original Materials

We are developing unique materials with good spring characteristics and good electrical conductivity that can withstand tens of thousands of bending operations.

Mass Productivity (Electroforming Process)

OMRON is the first in the world* to succeed in mass production of connectors that use electroformed contacts. (*According to in-house research, July 2011)

Applications

Device Inspection Pin, Pin Block

Customizable to inspection pin specifications tailored to the customer's device inspection process

USB-Type C inspection socket

Capable of various inspections of electronic devices equipped with Type-C connectors, such as communication inspection and high-speed charging inspection.

Battery (High-Current Device) Inspection Socket

High-current devices can be inspected by overlaying blade pins.

Technology Application Examples

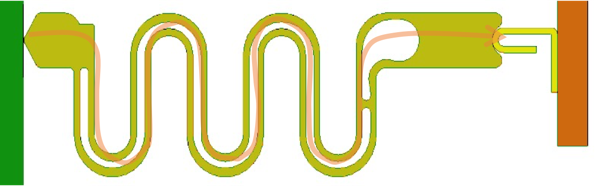

Microfabricated Spring Structure Through Single-Component Material

Supporting High-Frequency Inspection

Since OMRON's inspection pins contain only a single component, they have less loss and exhibit better high-frequency characteristics compared to conventional inspection pins.

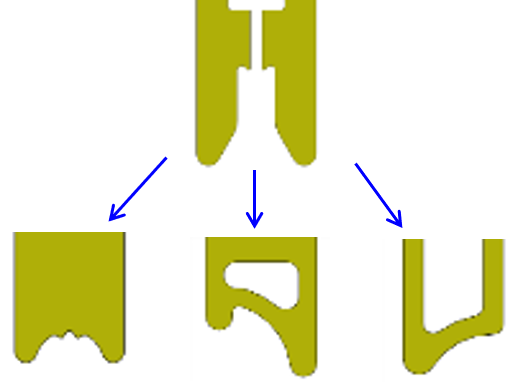

Customization of Contact Shape

High Pass-rate Inspection

OMRON's inspection pin contact part shape can be customized according to the inspection target (DUT). It ensures high inspection process pass rates.