CAE※ Analysis Technology

Simulation technology that enables manufacturing with theoretical backing and supports production process design

※computer-aided engineering

Features

Analysis of Contact Swaging Process

Manufacturing Optimization

Parts machining conditions are optimized by simulation

Stable Quality

Equipment design with sufficient rigidity ensures stable quality even in mass production

Effective Utilization of Energy

Optimized air-blow dust removal design helps reduce power consumption and realize environmentally friendly manufacturing

Application Examples

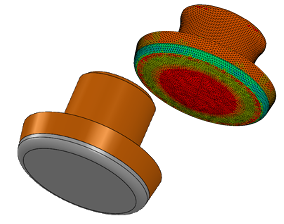

Manufacturing Optimization: Dynamic Analysis of Contact Swaging Process

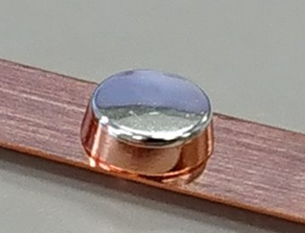

Electric Contact

Stress Analysis of Contact Swaging Process

Mass production of high-quality products has been realized by using CAE analysis to visualize invisible stress distribution and deformation during machining and by setting effective machining conditions to ensure quality.

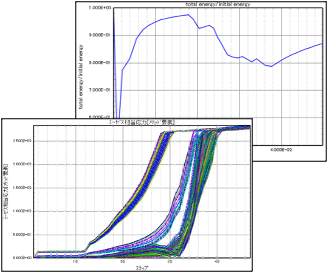

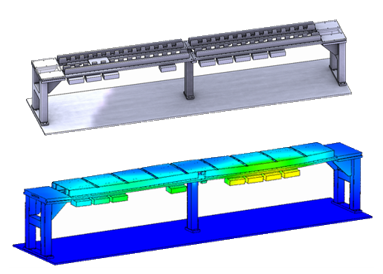

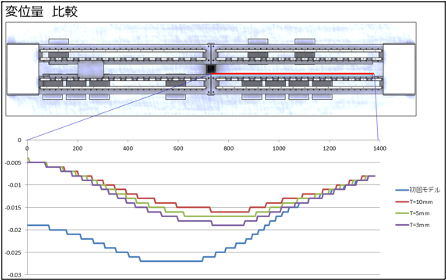

Stable Quality: Structural Analysis of Equipment Frame Deflection

Analysis of Equipment Frame Deflection

Since high-precision assembly is performed in the order of 1/100mm, it is necessary to predict and take countermeasures against mechanical fluctuations from both static and dynamic perspectives. CAE analysis is used to make predictions in advance to validate our design perfection, and verify the reproducibility on actual equipment, thereby realizing highly accurate manufacturing backed by theory.

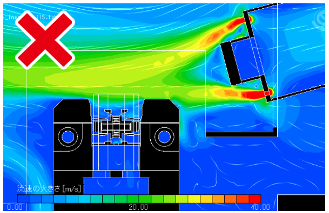

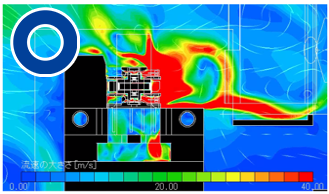

Effective Utilization of Energy: Airflow Analysis of Dust Removal Process

Air does not reach the parts.

Air has been blown to the target position.

Airflow Analysis of Air Blowing Process

Processes that can remove foreign matter with high accuracy are designed by optimizing the blow/suction nozzles' airflow through Airflow analysis. And promote environmentally friendly manufacturing by reducing compressor power consumption through wasteless use of the compressed air.