D6T MEMS Thermal Sensors

Contactless Measurement OMRON MEMS Thermal Sensors are able to detect the slightest temperature changes

-

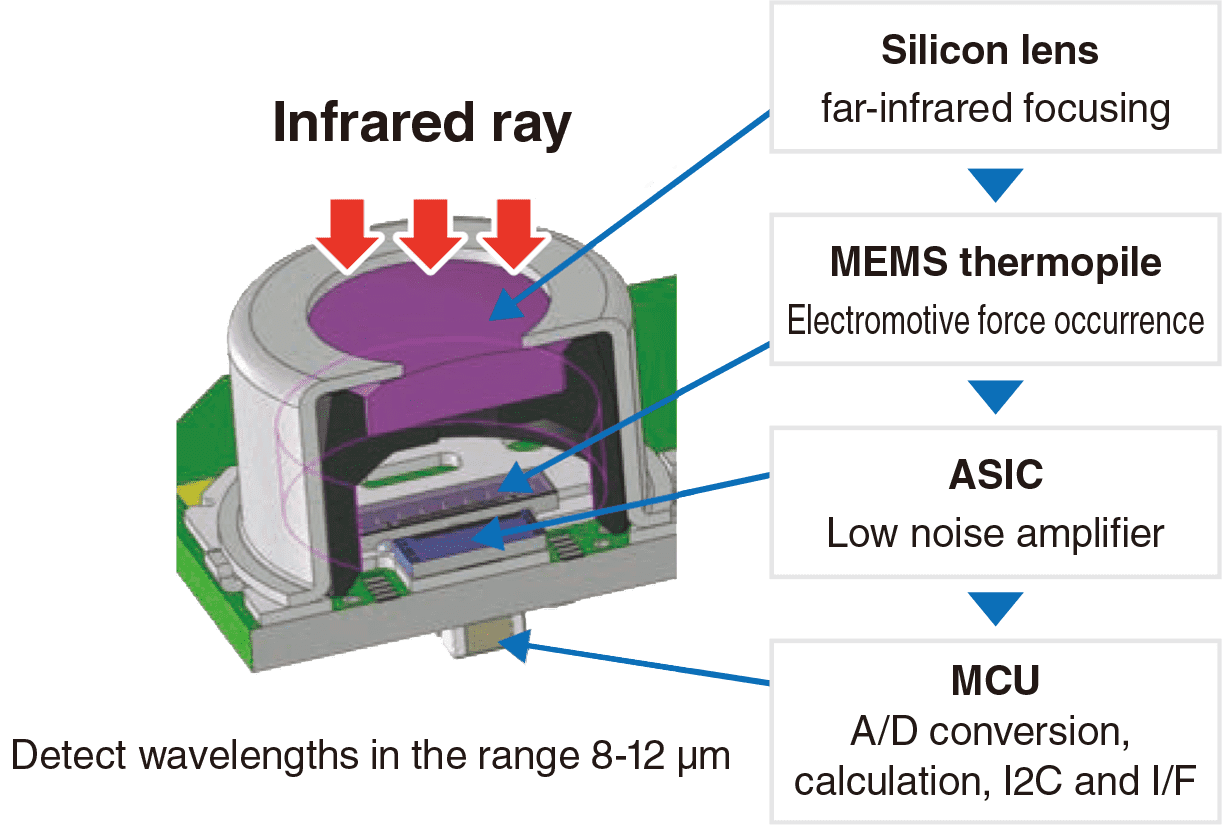

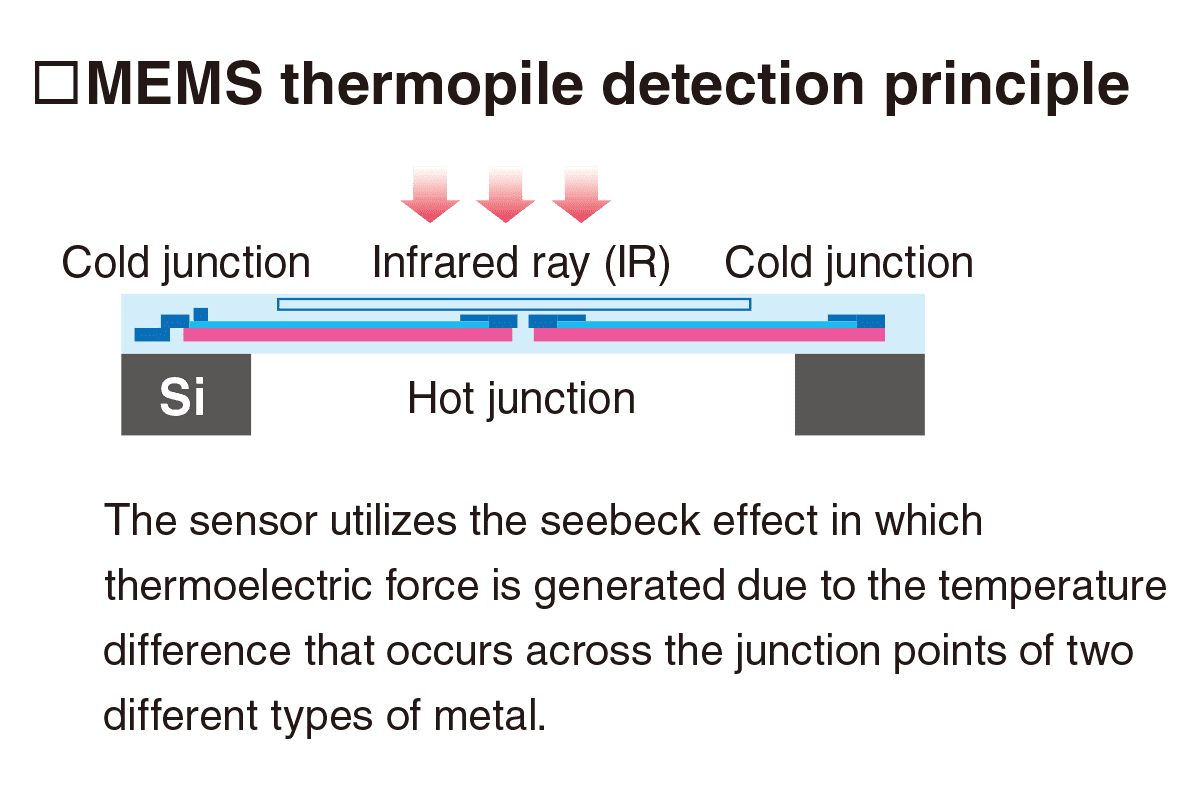

MEMS Thermal (IR sensor) measures the surface temperature of objects without touching them when the thermopile element absorbs the amount of radiant energy from the object.

- 1

-

Low noise

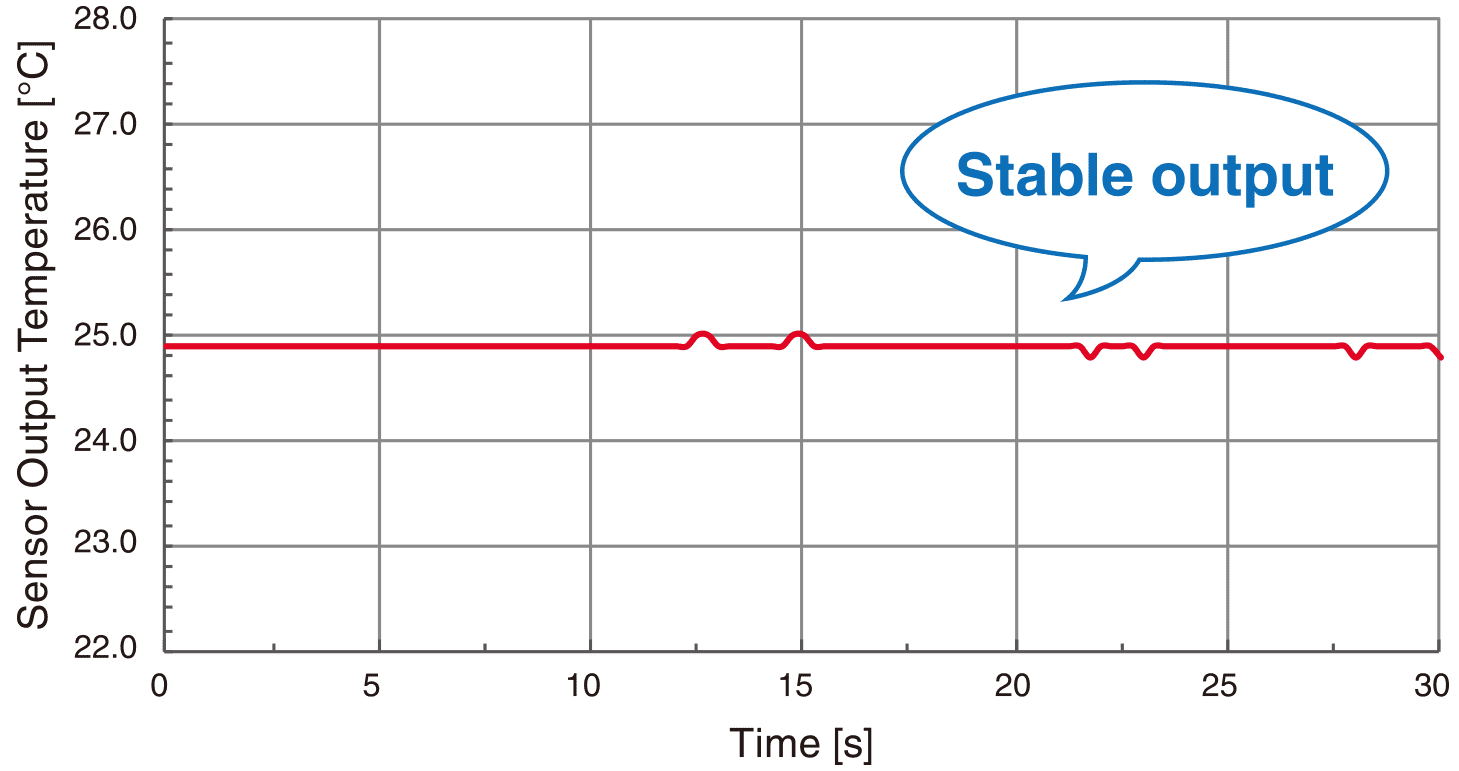

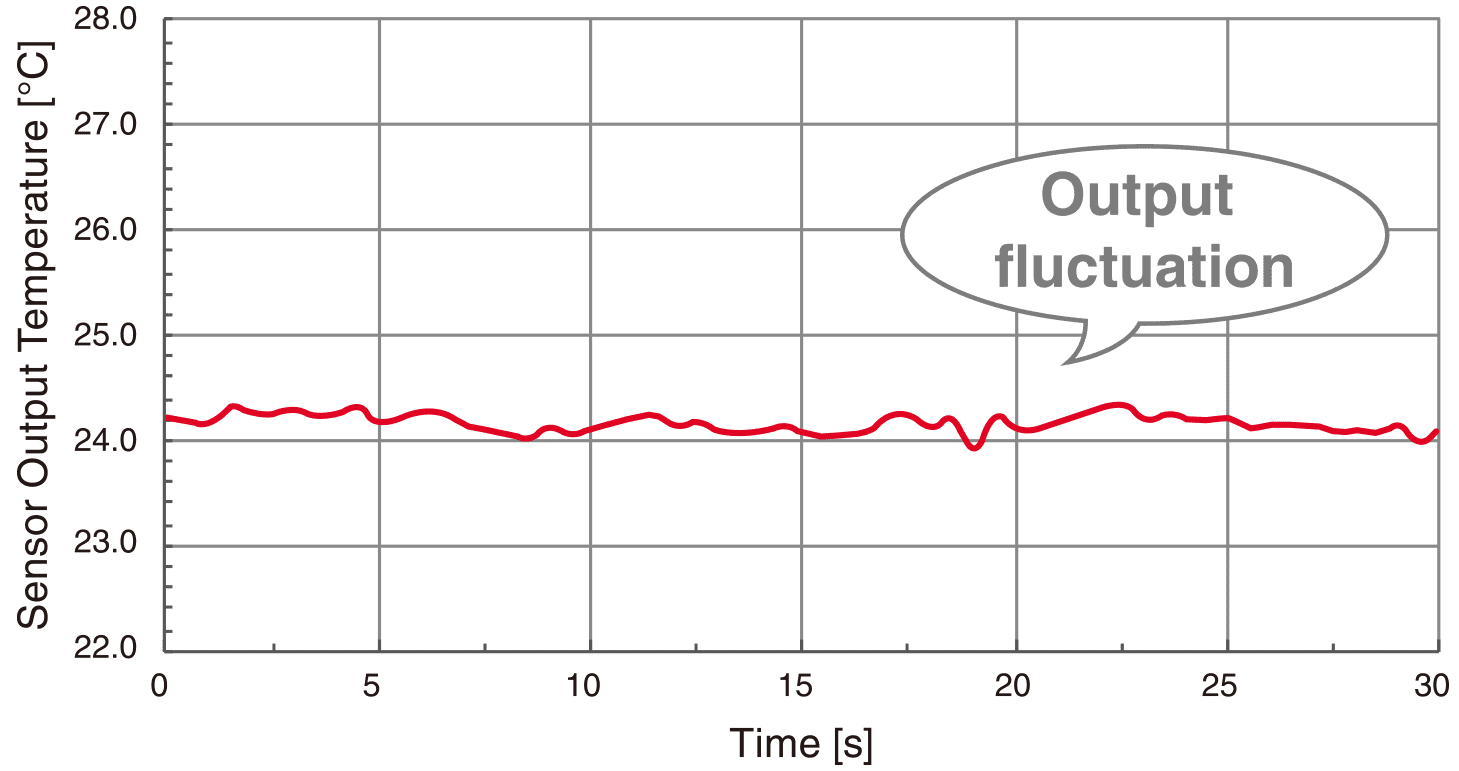

Market performance of over 6 million units*1 with a stable temperature output*2

*1: According to OMRON's research as of March 2022.

*2: Refer to the Noise Equivalent Temperature Difference (NETD) on page 12. - 2

-

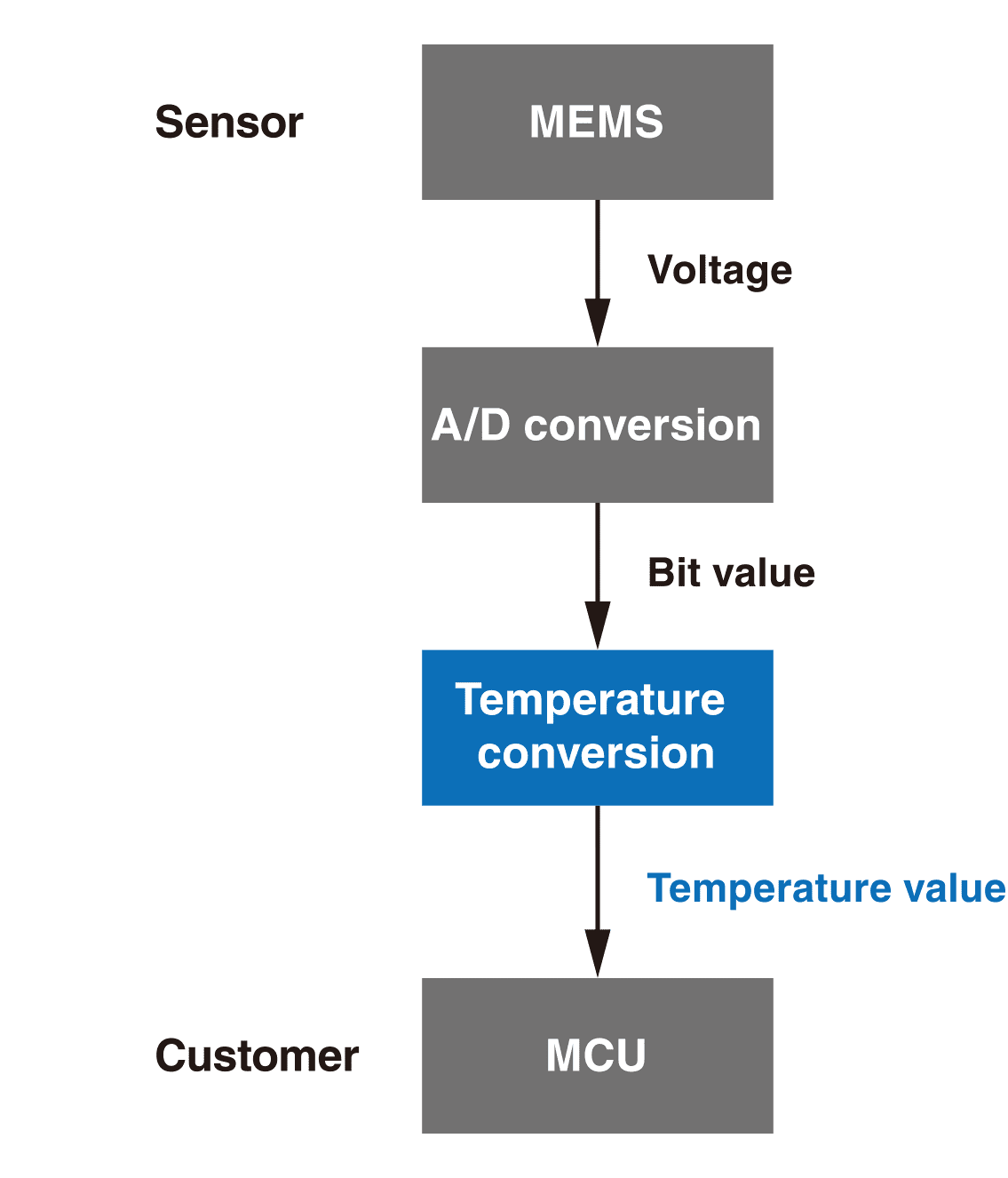

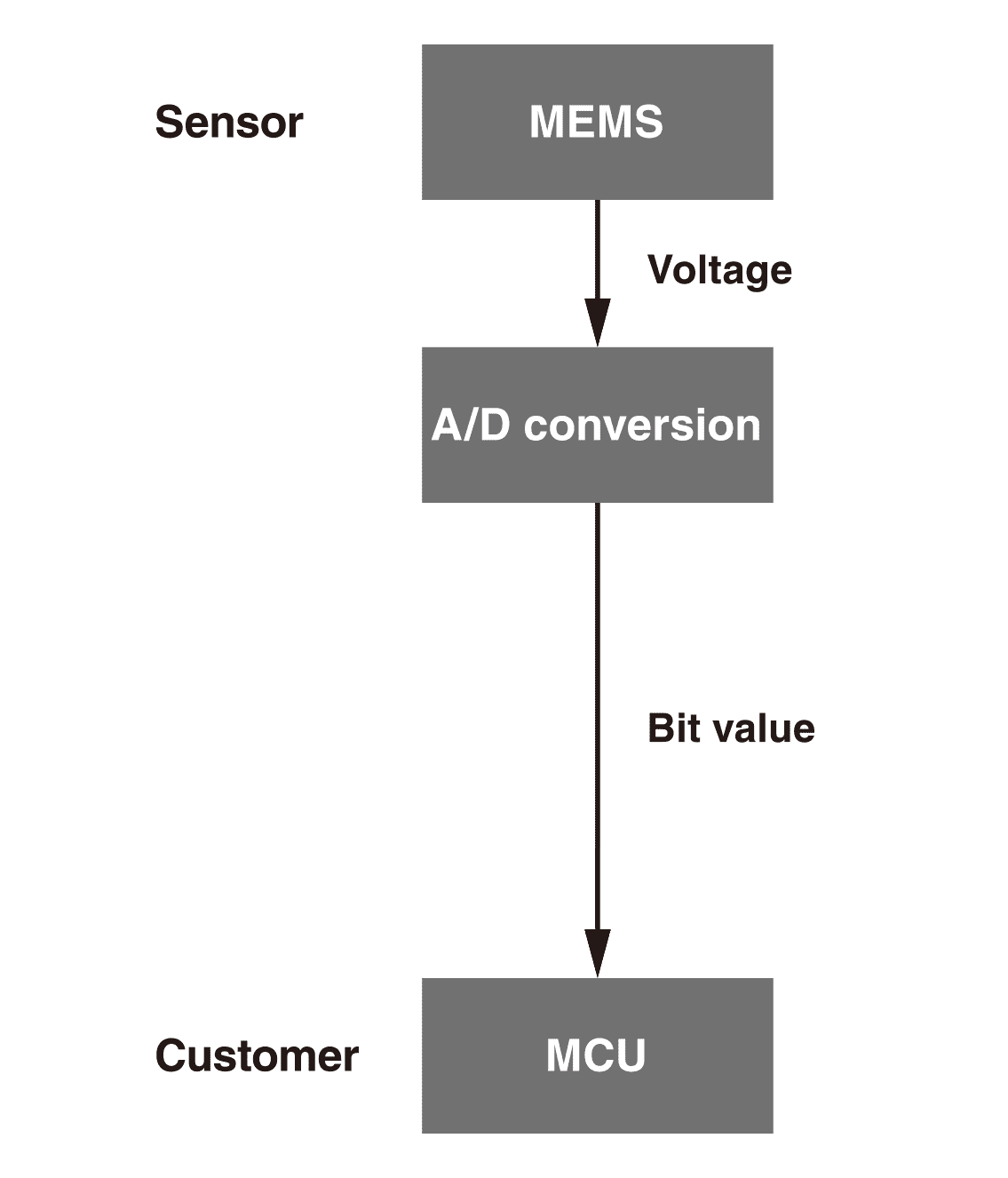

Easy connection

Direct temperature value output allows easy software design

- 3

-

Number of elements and temperature lineup

Variation of the number of elements (1 to 1024) x temperature range (-40 to 200°C)

- 1

-

High Precision

Market performance of over 6 million units*1 with a stable temperature output*2

*1: According to OMRON's research as of March 2022.

*2: Refer to the Noise Equivalent Temperature Difference (NETD) on page 12.

- Output was unstable in applications requiring high precision

- Stable temperature output

-

OMRON D6T-1A-01

Standard Equivalent Product

- Note 1. According to OMRON's evaluation method (30-second continuous measurement with a blackbody furnace at 25°C)

- Note 2. However, product specifications are not guaranteed.

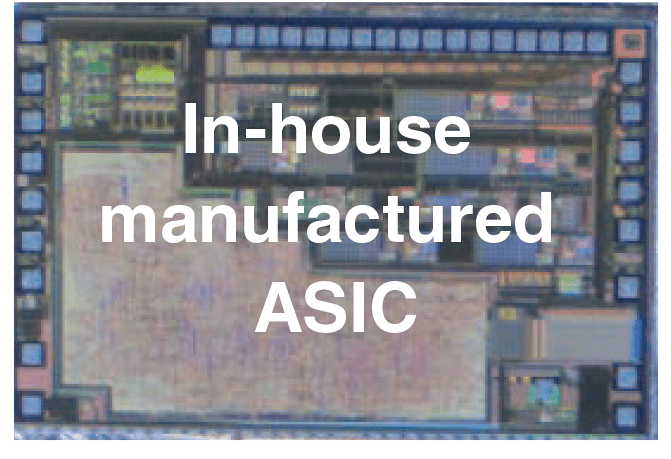

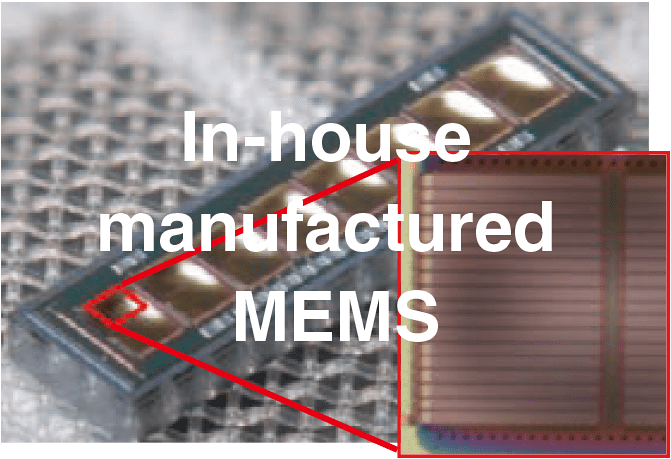

Achieves a low NETD*1 through the combination of ASIC and MEMS

reduce the noise of ASIC, thus achieving a low NETD*1.

- *1: Refer to the Noise Equivalent Temperature Difference (NETD) on page 12 of the data sheet.

OMRON's unique MEMS technology allows combining thermopile elements and ASICs into one package, resulting in ultra-compact footprint and high precision.

- 2

-

Easy connection

Direct temperature value output allows easy software design

-

OMRON D6T Temperature value output

-

CAN packaged thermal sensor from a competitor Bit value output

Evaluation of MEMS thermal sensors can be performed by connecting thermal sensor and harness to the platform.

However, please connect the communication signal voltage of the platform at 5.0 V, which is Vcc of thermal sensors.

| Sensor | Harness for Connection | Platform | Sample Code |

|---|---|---|---|

| D6T | D6T-HARNESS-02 | Raspberry Pi*1 | https://github.com/omron-devhub/d6t-2jcieev01-raspberrypi |

| Arduino*2 | https://github.com/omron-devhub/d6t-2jcieev01-arduino | ||

| ESP32 Feather*3 | https://github.com/omron-devhub/d6t-2jcieev01-arduino |

- *1. Raspberry Pi is a registered trademark of the Raspberry Pi Foundation.

- *2. Arduino is a registered trademark of Arduino LLC and Arduino SRL.

- *3. Feather is a registered trademark of Adafruit Industries LLC.

- 3

-

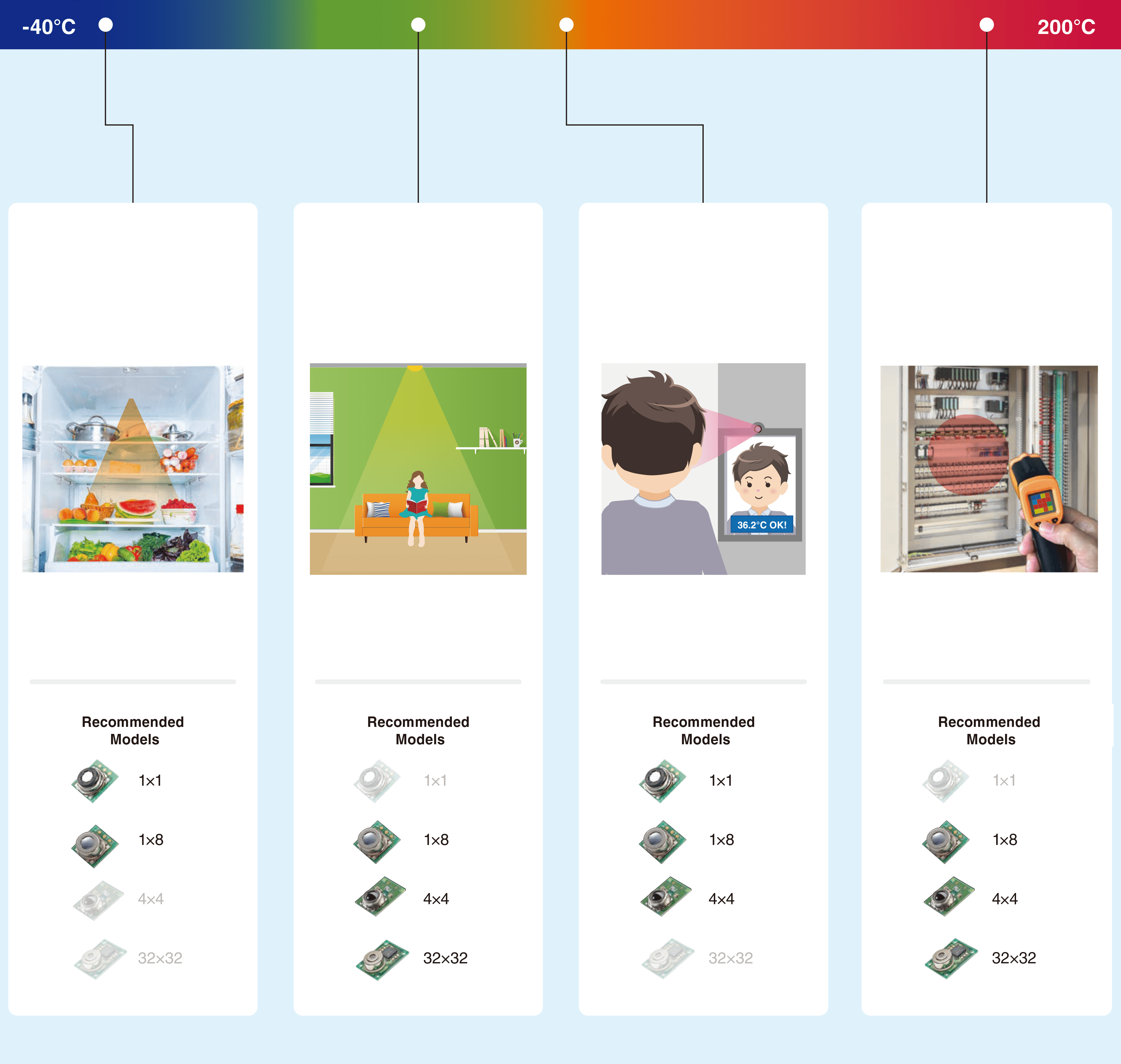

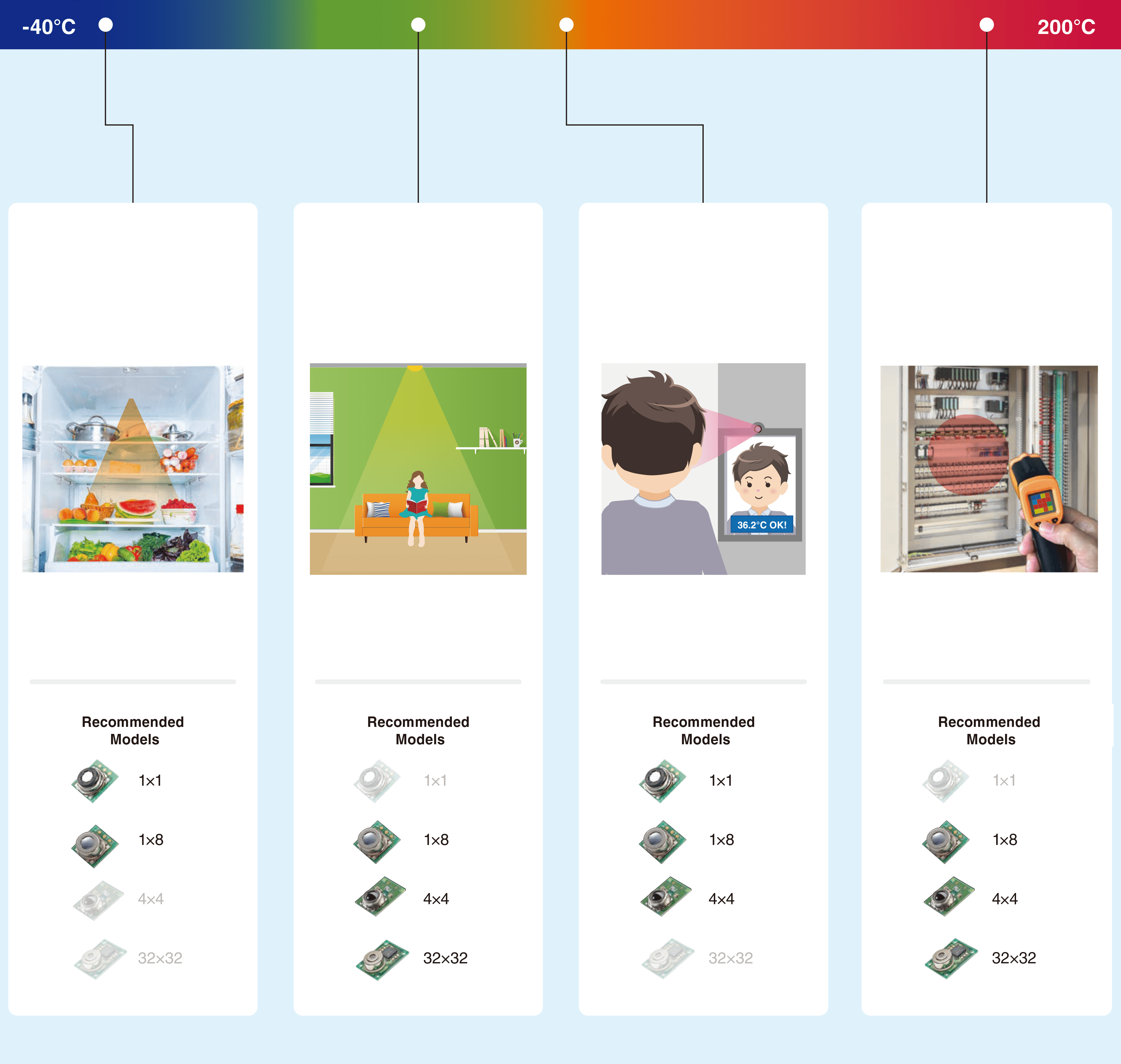

Number of elements and temperature lineup

Variation of the number of elements (1 to 1024) and the temperature range (-40 to 200°C)

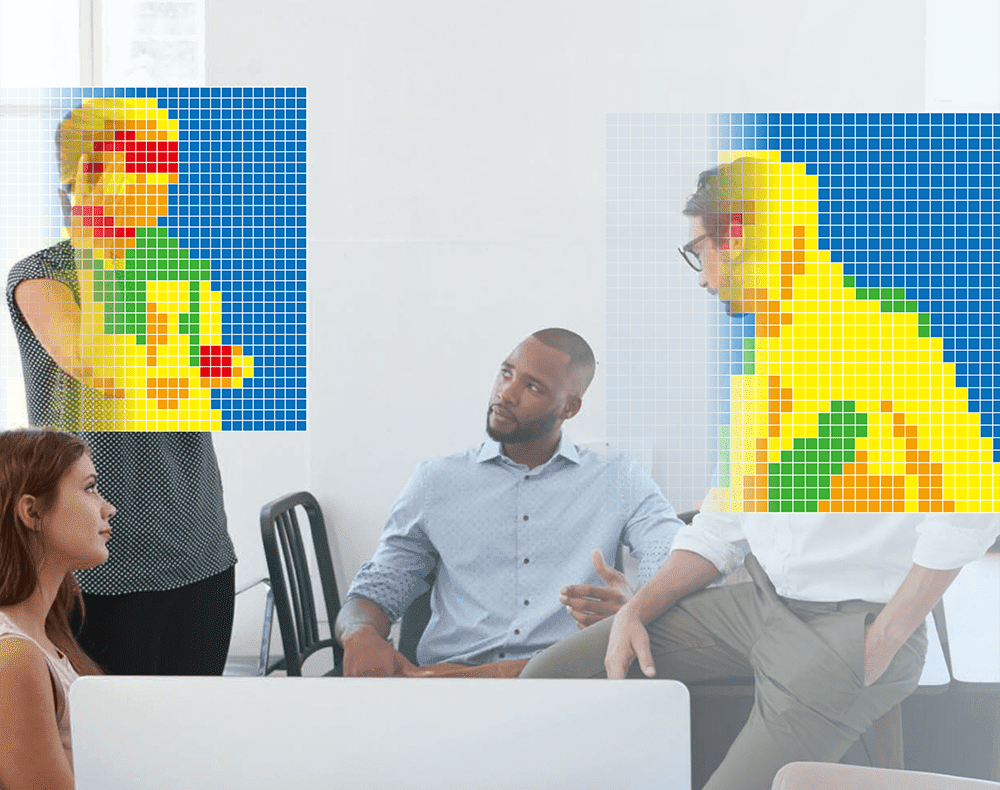

Example Applications

The sensors can be used in a wide range of applications, depending on the temperature measurement range.- Refrigerator Interior &

Room Temperature DetectionAble to detect temperature

from a long distance - Human Presence

DetectionAble to detect stationary

human presence - Screening of Humans

with FeverContributes to automated

non-contact temperature

detection - Abnormal High Temperature

MonitoringContributes to prevention

of fires due to overheating

- Home appliances

(refrigerators & air conditioners) - Air conditioners &

lighting systems - Room-Entry Management

Equipment - Transformers &

distribution boards

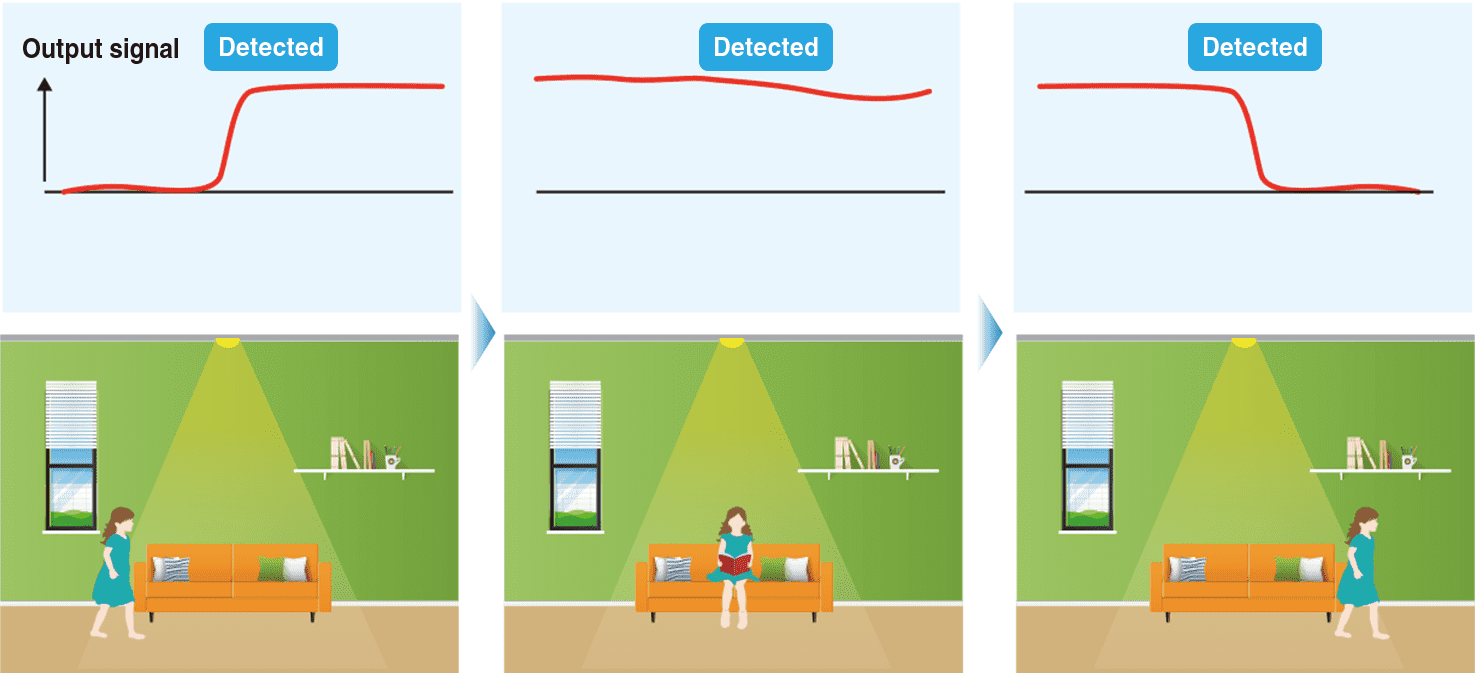

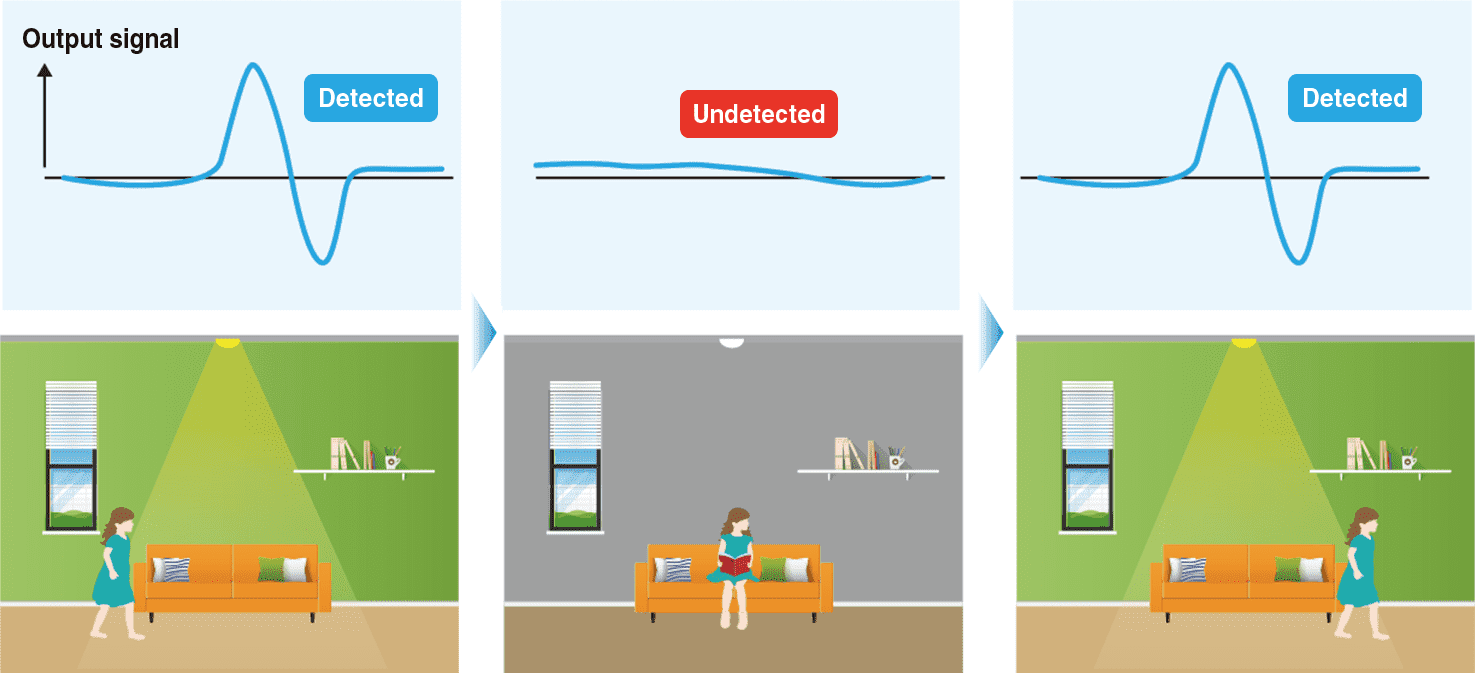

Comparison with Pyroelectric Sensor

Both the pyroelectric sensor and non-contact MEMS thermal sensor can detect even the slightest amount of radiant energy from objects such as infrared radiation and convert them into temperature readings. However, unlike pyroelectric sensor that relies on motion detection, non-contact MEMS thermal sensor is able to detect the presence of stationary humans (or objects).

- Pyroelectric sensor

- Converts temperature readings only when detecting “temperature changes in the radiant energy” in its field of view.

- MEMS thermal sensor (thermopile)

- Converts temperature readings by “continuously detecting the temperature of radiant energy” in its field of view