vol.250 November 2021

The maintenance effort must be reduced anyway.

Maintenance work to ensure site safety and product quality takes a lot of time and skill.

OMRON's connectors reduce maintenance man-hours both during planned and emergency maintenance with their unique structure and skill-less workability.

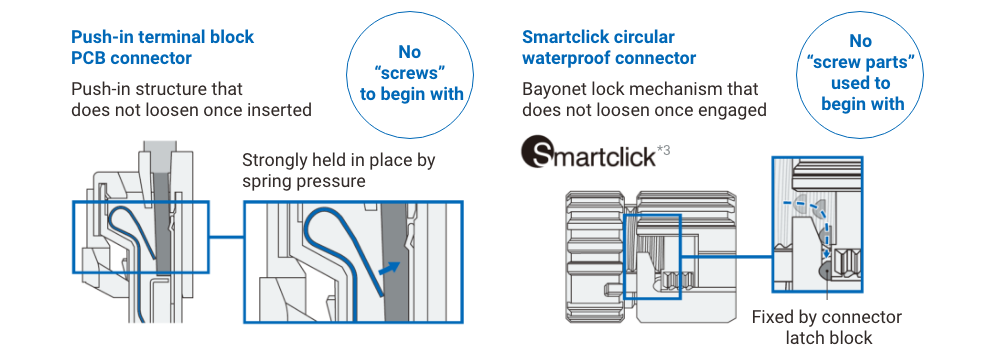

01 Zero retightening work during planned maintenance

The two screw-less structures eliminate the need for time-consuming retightening of screws before shipment, after transportation, and during periodic maintenance.

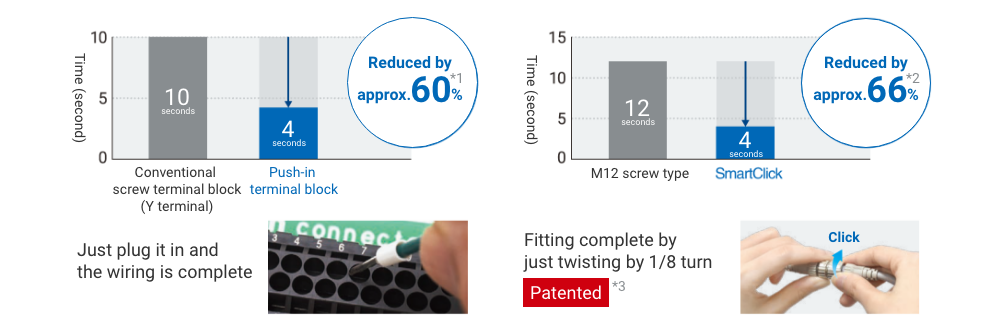

02 Reduced replacement time for emergency maintenance

Both the push-in and smartclick types do not require skilled workmanship or special tools, reducing replacement hours and downtime in the event of failure.

OMRON's connector product line that helps reduce maintenance man-hours

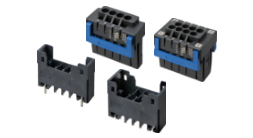

3.5 mm-Pitch Push-In Terminal Block PCB Connector |  |

|---|---|

PCB Terminal Block (Push-in type, SMT terminal 2.54 mm pitch) |  |

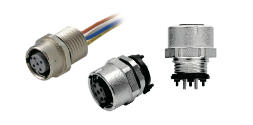

Round Water-resistant Connectors |  |

*1. According to OMRON's research in February 2021.

*2. Comparison between OMRON's M12 threaded connector and smartclick connector. Reference value based on our research.

*3. The notation "patent pending/patented" indicates that a patent is pending or has been patented in Japan. (As of October 2021) is a registered trademark of OMRON.

is a registered trademark of OMRON.

* Contents as of October 2021.

In the interest of product improvement, specifications are subject to change without notice