How to minimize power consumption for the circuit using Photomicrosensors (photointerrupters)?

ID: FAQE40018E

update:

Answer

In order to reduce the power consumption of the built-in type Photomicrosensors(photointerrupter), an LED pulse light emitter can be used.

Explanation

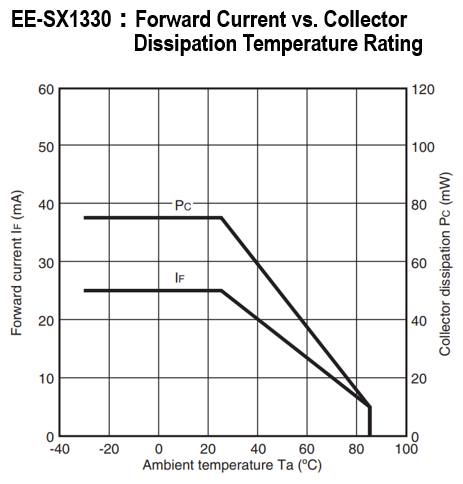

In recent years, the number of battery-powered devices has increased due to the advancement of mobility. Photomicrosensors have a large power distribution of LED light emission, and we recommend LED forward current (IF) of about 15 to 20 mA for normal power supply (see temperature rating chart). By changing the DC lighting of LED to pulse lighting, the power consumption of the Photomicrosensors can be greatly reduced.

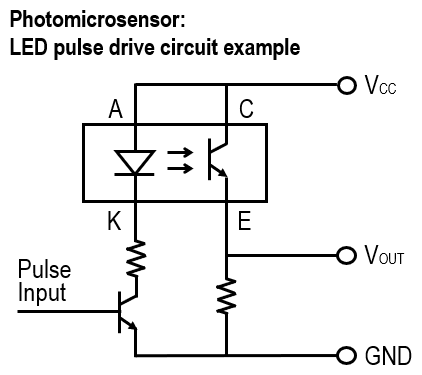

As an example, suppose that the LED is turned on by pulse signal input as shown below. In this case, the duty ratio of LED lighting is determined from the application and power consumption target value. Important measurements are 1) LED pulse current value (IFP) and 2) pulse width (PW). For stable LED lighting, it is recommended that the IFP be set to 5 mA or more. When the IFP is decreased, the light current (IL) is decreased and the load resistance must be increased. Increasing the load resistance slows down the response time. Keep this relationship in mind when designing your circuit. In addition, take the following variations into account when evaluating the product: the specified range of the light current, the aging of the LED, and changes in the light current due to temperature fluctuations. The pulse width is affected by the rise time of the phototransistor, so PW: 100 μs or more is recommended. Consider a photo IC output type with high sensitivity (fixed threshold) and high-speed response performance.

Quick tips

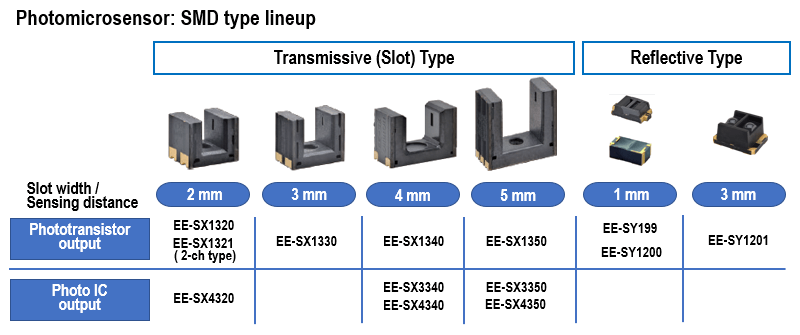

As devices become more mobile, demands for further downsizing are increasing. Consider the following SMD type Photomicrosensors that are useful for these applications:

| Product category | Sensors Photomicro Sensors |

|---|---|

| Classification | Usage, Applications |

| Related keywords |

|