What is the heat-resistant temperature for a relay when manually soldering, and what are the precautions for manual soldering?

ID: FAQE10059E

update:

Answer

Please refer to Explanation about manual soladering for our relays.

Explanation

- After smoothing the iron tip, solder according to the following conditions:

- Soldering iron: 30 to 60 W

- Iron tip temperature: 350°C

- Soldering time: Within about 3 seconds

- Use non-corrosive rosin for the flux because of the compatibility with the relay components.

Use an alcohol solvent with less chemical action for flux. - When soldering the terminals, make sure that no solder, flux, or solvent adheres to any part other than the terminals. If solder, flux, and/or solvent enters the inside, it could cause insulation degradation and poor contact.

For more information, see Safty Precautions for All Relays: 6-10 Automatic Mounting of Relays for PCBs.

Quick tips

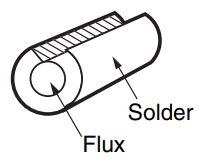

Note that, as shown in the figure below, some solders have a cut surface to prevent flux from scattering.

We have prepared a technical support page dedicated to high-capacity relays that explains in detail "I don't know" when using high-current, high-voltage PCB power relays, such as back EMF voltage (Zener diode and varistor) of the coil, holding voltage application circuit, recommended conditions for high-current substrate flow solder, the influence of magnetic fields, and precautions when connecting in series and parallel. Please also use this as well.

Click here for the high-capacity power relay technical support page.

| Product category | Relays Signal Relays Power Relays |

|---|---|

| Classification | Mounting, Storage |

| Related keywords |

|