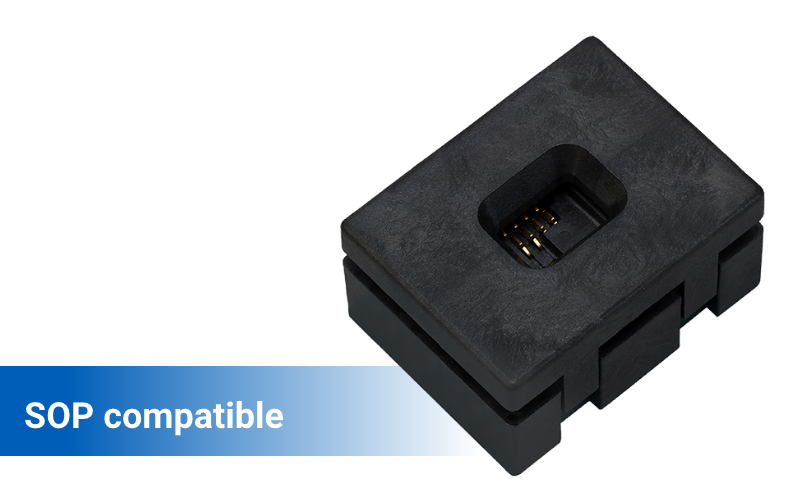

High measurement accuracy is achieved even for small sized SOP (small outline package) without damaging the device under test.

| Item | Specification |

|---|---|

| Pitch | 1.27/0.65mm or less |

| Stroke | 0.5mm or more |

| Plating | Au |

*Specifications are for reference only and may vary depending on the customized product.

We can custom design each pin and socket to suit the actual customer application. Please contact us for details.

No damage to customer’s products

No damage to customer’s products

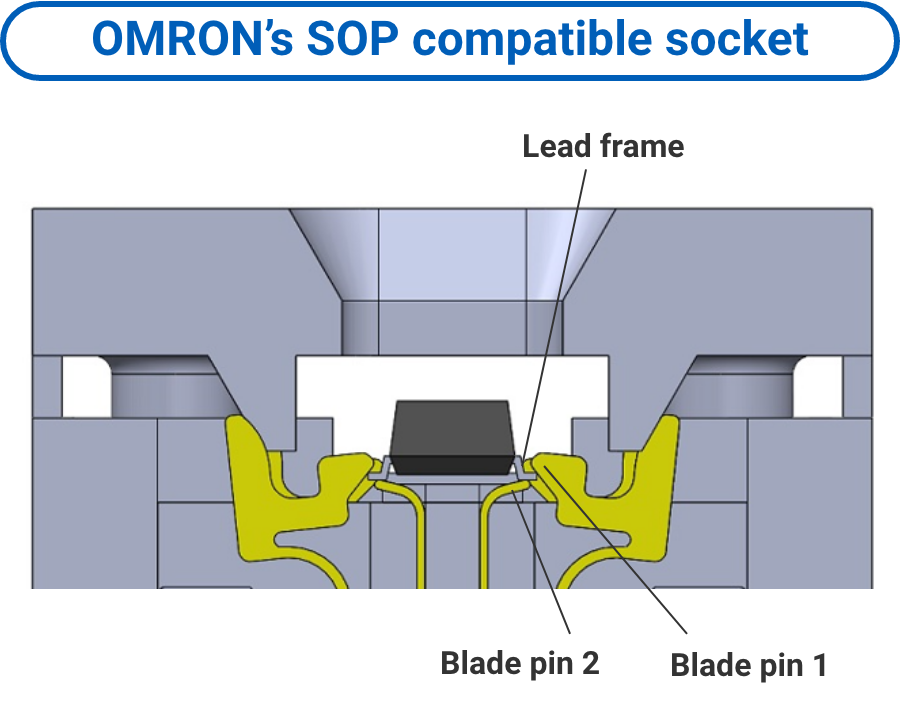

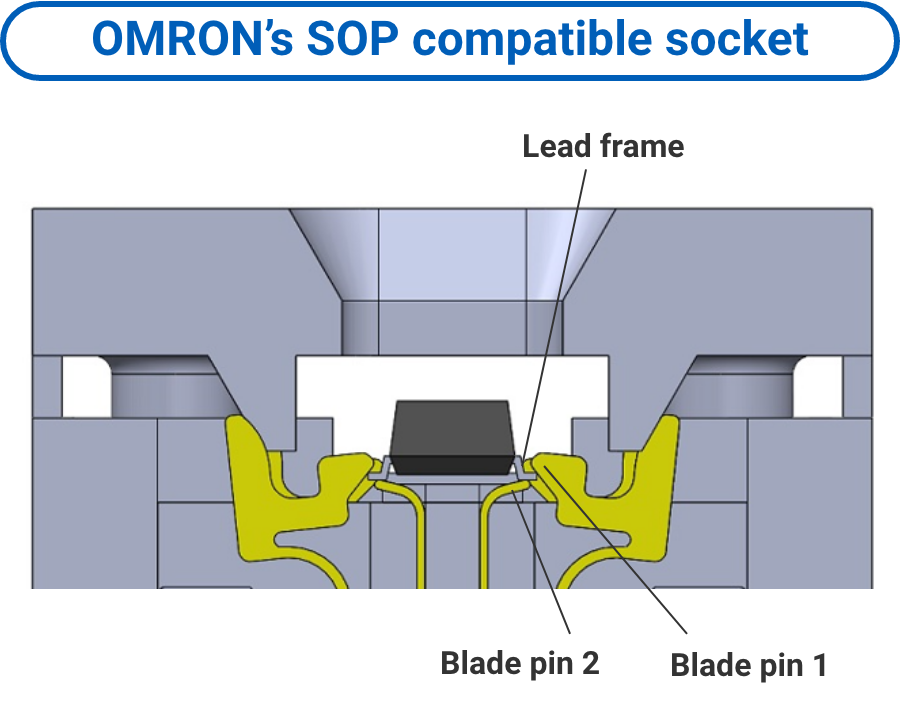

When measuring small devices under test, such as SOPs, frame deformation caused by the contact of testing pins is a challenge due to the fragility of the lead frame. OMRON’s SOP compatible sockets use blade pins that are structured to clamp the lead frame of the device under test from both sides.

Stress is hard to be applied, preventing deformation and damage of the lead frame during inspection.

Gently clamp the lead frame of the device under test from both sides with blade pins to prevent deformation and damage to the lead frame.

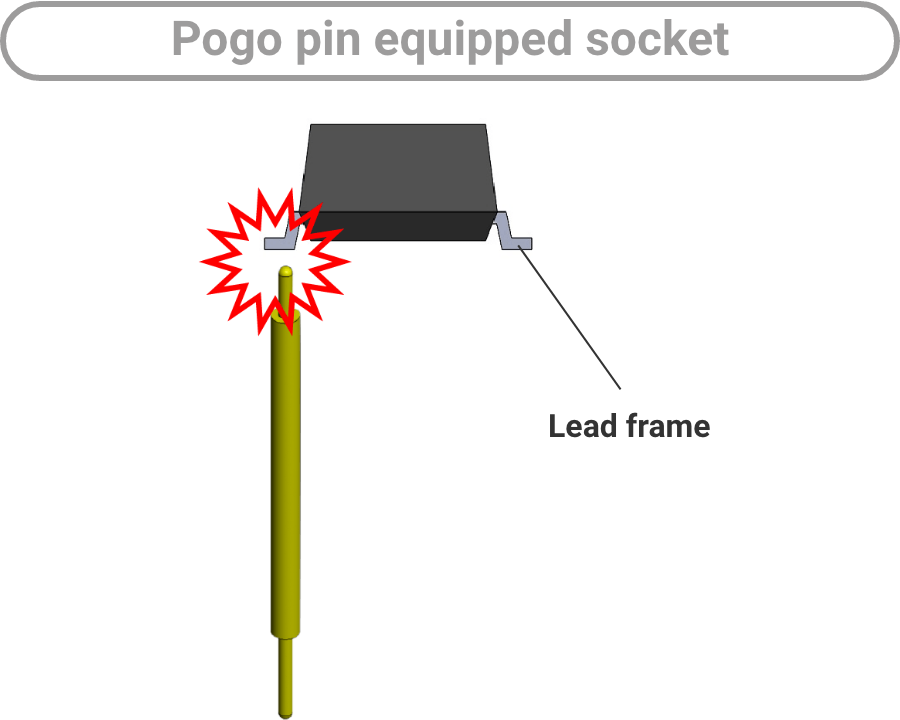

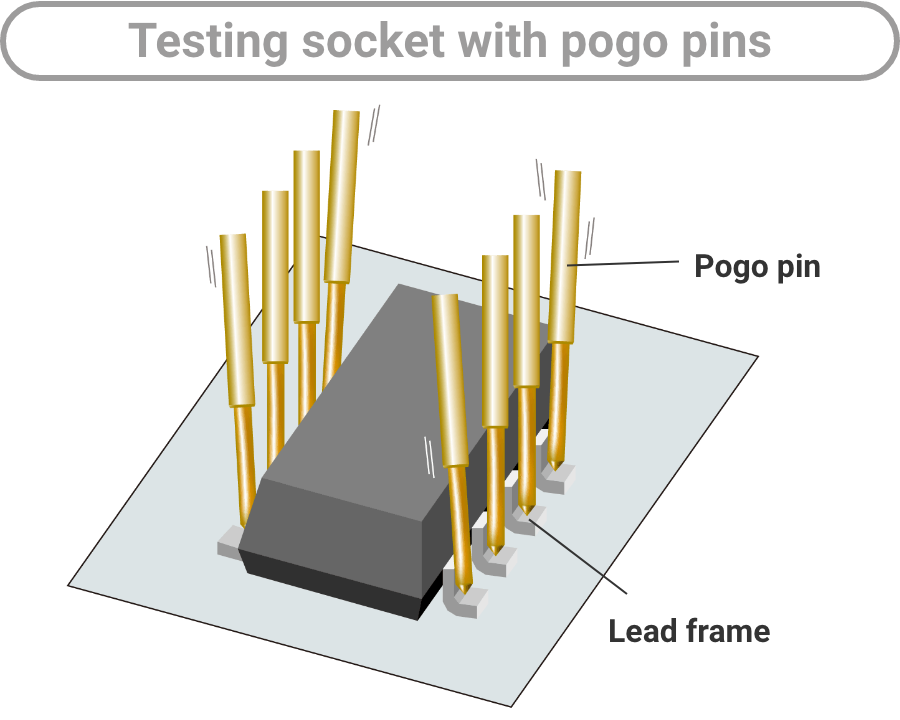

The lead frame is deformed because the rod-shaped hard testing pin is pressed against the fragile lead frame.

Accurate measurements even in a small package

Accurate measurements even in a small package

In the case of small and wobbly devices under test, such as an SOP package, it is difficult to accurately inspect each terminal by pressing a rod-shaped pogo pin against the terminal. OMRON’s SOP compatible type contacts the lead frame in such a way as to clamp it from both sides, enabling the testing pin to be pressed with accurate and sufficient contact force even for an SOP sized device under test. The SOP compatible type provides stable electrical contact and highly accurate measurements.

Stable contact is achieved by clamping the lead frame of the device under test from both sides with blade pins.

The terminal on the inspection side is rod-shaped and makes point contact, so it is difficult to accurately bring into contact the terminal to the lead frame of the small and wobbly device under test.

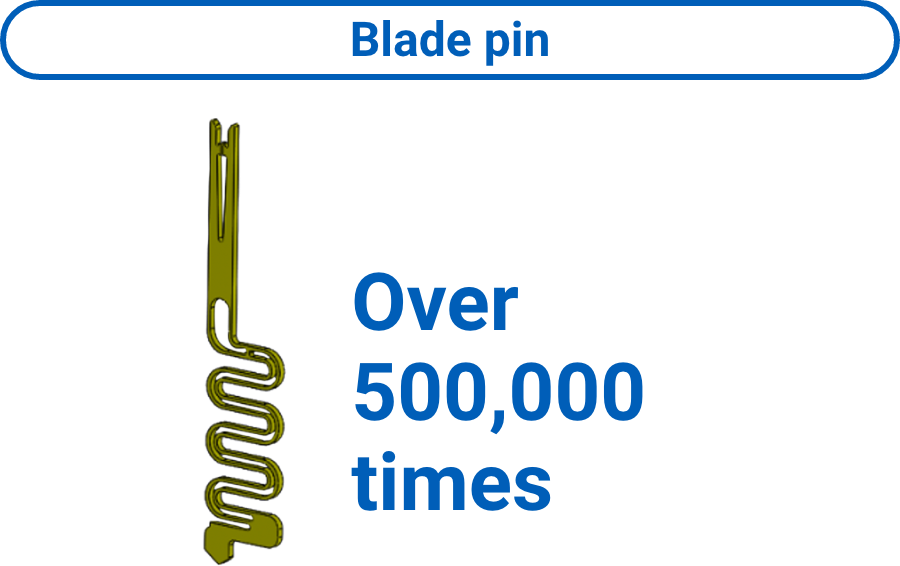

High durability and reduced maintenance

High durability and reduced maintenance

OMRON’s SOP-compatible sockets are five times more durable than pogo-pin sockets, due to OMRON’s original material blend* and custom design proposals that are suitable for customers’ applications. This greatly reduces the frequency of testing socket replacement at the inspection site, contributing to improved production efficiency.

*Patent No. 5077479

*An example of B-to-B connector inspection