vol.258 July 2022

"Shortcut Maintenance" for efficient maintenance and servicing

To reduce the time required for maintenance and servicing, it is important to identify abnormalities at an early stage, determine the cause instantly, and replace or repair them in the shortest possible time.

To facilitate these three processes, OMRON has focused on "shortcut maintenance", which reduces the workload itself. The electronic mechanical components that make this possible contribute to efficient maintenance and servicing.

Reducing the workload allows for more efficient maintenance and servicing.

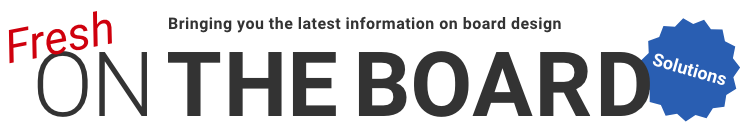

Shortcut the time and effort required to check the control unit during sensor installation and maintenance

[ NEW ] |  |

|---|

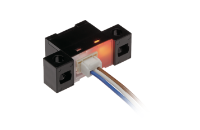

Shortcut the time required to open equipment in case of trouble

Built-In Resistor Sealed Ultra Subminiature Basic Switch D2AW-R |  |

|---|

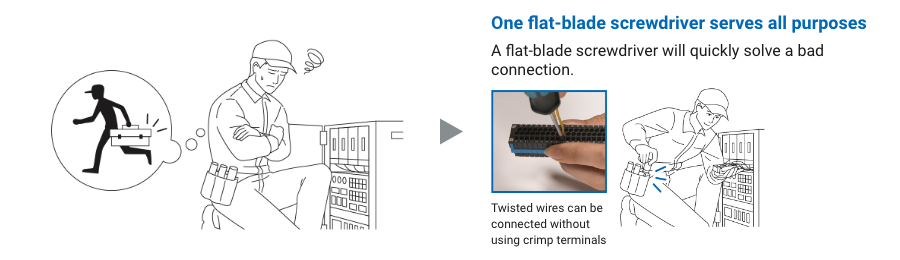

Shortcut the time and effort to pick up special tools for connection and adjustment

XW4M/XW4N 3.5 mm-Pitch Push-In Terminal Block PCB Connector |  |

|---|

* Contents as of June 2022.

In the interest of product improvement, specifications are subject to change without notice