Setting detection switches as the standard for operation switches for mouses

Interview with the developer of OMRON's switches for mouses

Since its founding, OMRON has developed microswitches for use in a wide variety of applications. Microswitches are used for opening and closing doors, detecting the position of objects, among others.

Today, OMRON's microswitches have established a firm position as global operating switches for mouses. Originally, it started around 1988, when a mouse manufacturer liked the operational feeling of OMRON's detection switches. At that time, there were various obstacles that hampered improvements to the microswitch for mouses. We interviewed the developer at the time about the path of OMRON's switches for mouses.

Contents

- D2F, microswitch adopted for its operational feeling as the first step in switches for mouses

- "Unparalleled long life", which had not been required for detection applications

- Providing a stable click feeling; OMRON's commitment to quality

- Not only "feeling" but also "sound" is an important factor

- Difficulty in maintaining "what is ordinary" for customers

- New challenges for even higher quality

- Developer Makino's desire to be close to customers through "customer value creation"

D2F, microswitch adopted for its operational feeling as the first step in switches for mouses

Did you know that decades ago reception rooms had electronic lighters for cigars? The D2F, the first switch for mouses, was used as the ignition switch for the electronic lighter.

By following the path of the mouses, the D2F achieved rapid growth within a few years, reaching five times the size of its business at the time.

OMRON’s best-selling D2FC series, originally introduced as an ultra-compact, long-life product, has maintained annual sales of more than 70 million units* in the mouse switch market for nearly 20 years. OMRON's switches for mouses have a 40-year history, starting with the D2F series.

* As of October 2022

Osamu Makino

Business Management Division HQ Development Division

Device and Module Solution Company

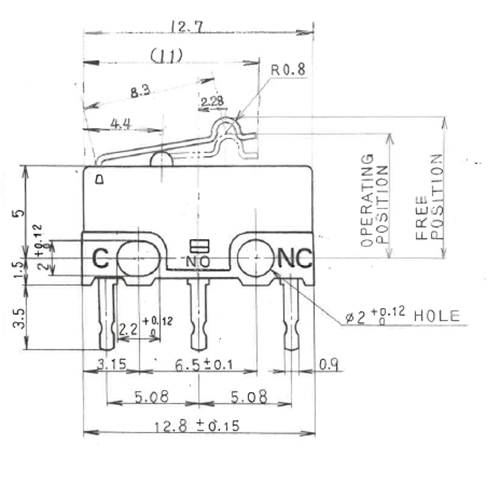

D2F at that time (1988)

* Due to the specifications at that time, they differ from the current D2F specifications.

At that time (1988), personal computers were still rare, and it was difficult to imagine how switches for mouses could be a viable business. There was also confusion surrounding the market for mouses with many different types of switches in use, and it was difficult to tell which switch would dominate the market.

In this era of mouse switch wars, OMRON's D2F detection switch caught the eye of a well-known mouse manufacturer. While there were tactile and other operating switches that focused on the operational feeling, it was the "after stroke" function of the detection switch that caught the customer's attention. The D2F with "after-stroke" allows for further push-in from the push-in position, thus minimizing the burden on the fingers. In a mouse that performs repeated clicking movements, the finger-friendly D2F detection switch happened to be the perfect product for the customer's needs.

Furthermore, in response to the trend toward lighter, thinner, and smaller products in the detection switch market, the D2F, whose value lies in its compact size, was perfect as a switch for a mouse. We therefore embarked on the modification of the D2F to satisfy the customer's request.

This was the first step for microswitches to be used not for detection but for operation switches.

"Unparalleled long life", which had not been required for detection applications

When we started modifying the D2F for use in mouses, the biggest obstacle was "mechanical durability performance = service life". For applications such as a mouse where the switch is turned on and off repeatedly, the required number of guaranteed operations is one million, whereas the mechanical durability performance of the D2F, which was designed for detection applications, was only 300,000 operations. Microswitches were overwhelmingly insufficient in number of operations.

At that time, there were no CAE analysis tools, and it was not easy to perform stress analysis, stress amplitude analysis, and operating characteristic analysis, which are now commonplace. With little knowledge to significantly improve contact welding and service life, we repeated experiments and hand calculations to predict improvements. After repeated trials and errors, including changing the shape and material of levers and movable pieces, we were able to provide a modified product that satisfied the customer's requirement of one million operations.

The part shapes and other features studied at the time were later incorporated into mouse switches such as the D2FC, and products with a guaranteed service life of up to 60 million operations, 60 times longer than at the time, were also released.

Providing a stable click feeling; OMRON's commitment to quality

As the D2F was adopted for mouses, we gradually received inquiries from other companies, and the mouse business grew at an accelerated pace. At the time, the "operational feeling" and "long life" were highly supported by our customers, but another highly appreciated feature was "process quality".

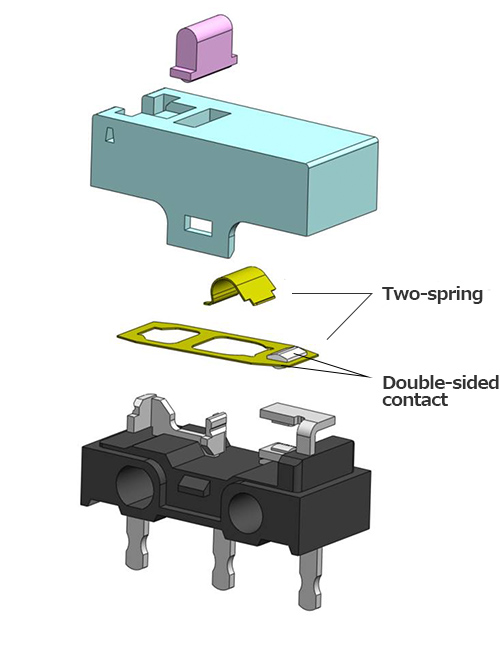

Applications such as mouses, which require high frequency switch operation and the same left and right click feeling, are extremely sensitive to variations in quality. Therefore, in order to minimize the variation of the click feeling, OMRON introduced a moving piece assembly machine with two-spring mechanism, which was the first of its kind for OMRON in those days. By taking measures against foreign matter and load variation through automated machine production, we are now able to provide products that are stable and highly reproducible. As a result, "OMRON quality" was recognized for mouse switches, and sales volume grew to about eight times that of the start-up.

Not only "feeling" but also "sound" is an important factor

Along with the expansion of the mouse business, the D2FC mouse-specific switch was born in 1999. It was a product optimized for the needs of mouses, but this was the first time we received complaints from our customers about the "sound" of the product.

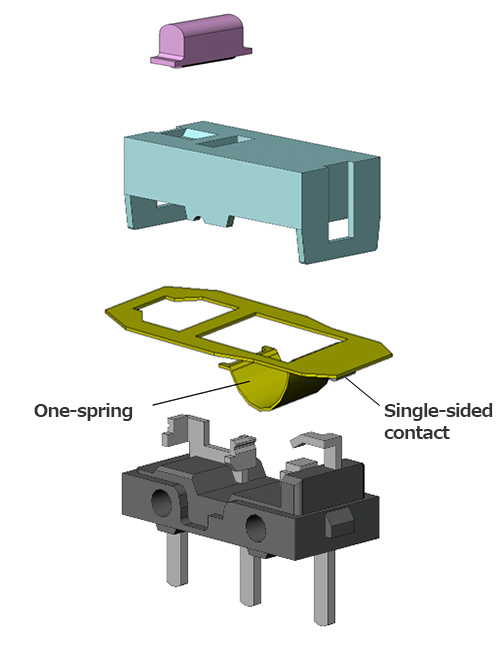

The function of a mouse does not require the use of switching between two circuits. Therefore, the D2FC has been improved from a two-spring, double-sided contact structure to one-spring, single-sided contact structure as a mouse-specific switch. This structural change resulted in a subtle change in the contact opening/closing sound. For customers accustomed to the sound of the D2F, however, the contact opening/closing sound of the D2FC was disconcerting. The sound of the D2F had become the de facto standard.

Structure of D2F

Structure of D2FC

Naturally, we had proceeded with the design while being conscious of the operating characteristics and the click feeling. However, there is no sound generation or resonance as a function of the switch. At the time, when our experience with switches for mouses was still limited, we had no idea that we would receive complaints about the "sound". In order to respond to this situation, we collected a lot of sound data, compared them, and showed our customers the similarities in sound quality.

Difficulty in maintaining "what is ordinary" for customers

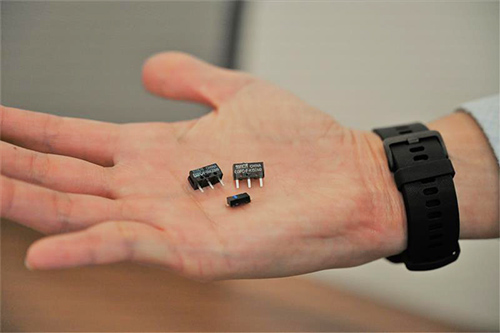

OMRON's switches for mouses

It may seem easier to "maintain without changing" than to "create new value". In fact, from the perspective of the field, however, "maintaining without changing" is extremely difficult. With many factors that cannot be easily changed, such as feeling, sound, and size, the demands of our customers are becoming higher and higher. If materials and shapes of parts are changed to further enhance mechanical durability, the click feeling will change slightly. The "difficulty of maintaining what is ordinary" is how to bring them closer to their original state with other elements.

New challenges for even higher quality

As high-performance mouses and other devices for gaming applications continue to expand in scale, the demand for click precision of switches is further increasing. It is practically impossible to produce switches with exactly the same load without any error. However, due to the characteristics of the mouse, the less difference there is in the click feeling (load) between the left and right buttons of the mouse, the more comfortable it is for the customer to operate. One of the factors contributing to load changes is the material. Even in the materials we purchase, there are variations in hardness, thickness, among others at levels that are not normally apparent. Differences in materials also cause miniscule differences in the way the spring bends and returns, which leads to minute changes in load.

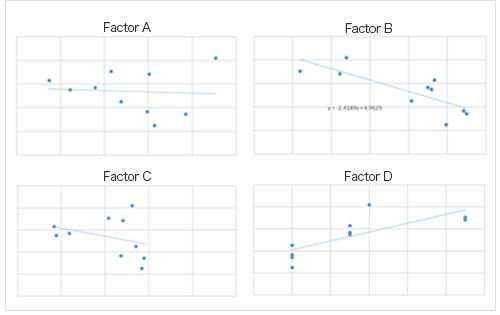

Therefore, we are currently utilizing statistical methods to provide products that satisfy our customers.

We are analyzing the correlation among various factors that are assumed to affect load, based on accumulated on-site data, and examining new process control methods. In order to provide products that satisfy our customers, we are working together with our on-site members to take on new challenges and achieve a higher level of production system and finer load control.

The correlation of dozens of complex factors is being verified, and the effects of the factors on loading errors and the need for factor control are being discussed among the members.

Developer Makino's desire to be close to customers through "customer value creation"

Osamu Makino

Business Management Division HQ Development Division

Device and Module Solution Company

Looking back on my long life with switches, I realize once again that OMRON's switches for mouses are what they are today thanks to the support of all the people who have been involved in the development of switches for mouses.

The sales members were very close to the customer and made sure that the customer's voice was heard. In order to provide our customers with stable, high-quality mass-produced products, our production members devised a variety of quality control measures. Planning members worked to coordinate delivery dates to ensure products were delivered to customers. All the members involved in the business worked together to support OMRON's business for mouses.

I am proud to say that OMRON is a manufacturer that can create business together with its customers. In the spirit of "creating customer value", we will continue to contribute to the expansion of OMRON's switch business by creating products in line with customer applications.