What are the preheating and soldering temperature conditions for automatic soldering on PCBs?

ID: FAQE10056E

update:

Answer

The conditions are different for through-hole flow and surface-mount reflow. Refer to Explanation for details.

Explanation

Through-hole mounting type

[1-1 Preheating process]

Preheating: 110°C max. / Duration: Within 40 seconds

- Caution

- Be sure to preheat to improve the solderability.

- Preheat under the above conditions.

- Do not use a relay that has been left in high temperature for a long time due to equipment failure which may cause a change in initial characteristics.

- Availability of preheating

- Closed type: Not applicable

- Flux-resistant type: Applicable

- Plastic-sealed type: Applicable

[1-2 Soldering]

Solder temperature: ca. 260°C / Soldering time: Within about 5 seconds

- Caution

- The flow solder type is recommended for uniformity of quality.

- Adjust the fluid level so that the solder does not overflow on the PCB.

- Availability of automatic soldering

- Closed type: Not applicable

- Flux-resistant type: Applicable

- Plastic-sealed type: Applicable

Surface-mount type

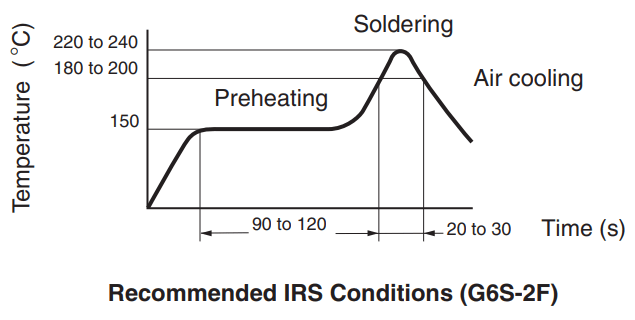

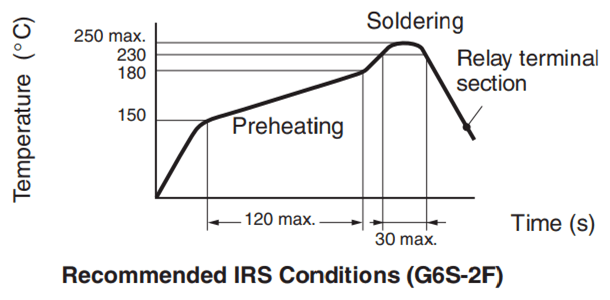

Examples of recommended soldering conditions for the IRS (infrared reflow soldering) are shown in the following temperature profile (PCB surface).

- Recommended soldering conditions may differ for each relay. Please check individual specifications before use (refer to the Precautions for each model).

- Do not soak the product in cold liquid such as cleaning solution immediately after soldering. Doing so may damage the seal.

- Do not soak the relay in the solder bath. Doing so may cause malfunction due to resin deformation.

[Solder for mounting: Lead-free solder]

[Solder for mounting: Lead solder]

For more information, see Safty Precautions for All Relays: 6-10 Automatic Mounting of Relays for PCBs.

Quick tips

- After automatic soldering, immediately blow air to cool the relay and other components so that they do not deteriorate due to the heat of soldering.

- You may clean the plastic-sealed type but do not soak it in cold liquid such as cleaning solution immediately after soldering.

Doing so may damage the seal.

*Precautions: Cooling is required for flux-resistant and plastic-sealed relays.

We have prepared a technical support page dedicated to high-capacity relays that explains in detail "I don't know" when using high-current, high-voltage PCB power relays, such as back EMF voltage (Zener diode and varistor) of the coil, holding voltage application circuit, recommended conditions for high-current substrate flow solder, the influence of magnetic fields, and precautions when connecting in series and parallel. Please also use this as well.

Click here for the high-capacity power relay technical support page.

| Product category | Relays Signal Relays Power Relays |

|---|---|

| Classification | Mounting, Storage |

| Related keywords |

|