vol.280 May 2024

What can relay protection structuring do?

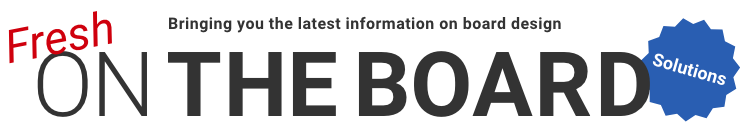

Electronic components, especially relays, need to satisfy many environmental requirements of the market, such as environmental performance, explosion-proof performance, and long life. These requirements ensure the diversification of equipment usage environments.

In response to these requirements, OMRON supports product development that is compatible with each usage environment by providing customers with components that employ several types of protective structures.

OMRON's relays respond to the diversification of usage environments with their protective structures.

PCB Cleaning

Sealed with resin to allow cleaning, contributing to equipment maintenance.

Application example

The PCB is cleaned during maintenance to prevent electrical leakage.

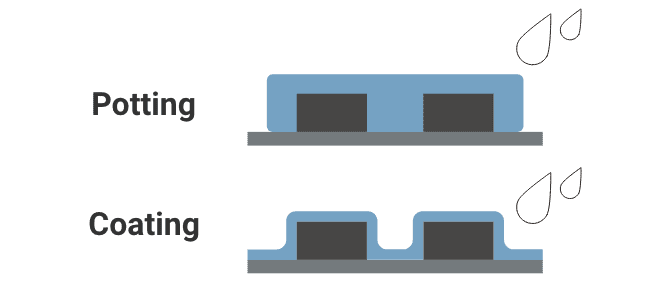

Water-proof / Moisture-proof

Sealed with resin to prevent water from entering.

Application example

Used in high temperature and high humidity, or in environments subject to water.

Note: Potting and coating are not within the scope of the warranty, so please consult your OMRON representative.

Searching for products that meet your needs

Parametric search

![Scan the QR code. Parametric search => Press [Open filters]. => Select 'Sealed' from 'Enclosure' to display the corresponding products.](/us-en/sites/components.omron.com.us/files/2024-05/onboard_280_1_08_en.png)

Explosion-proof Standard Certification

The structure is designed so that the contact will not trigger ignition. *1

Application example

Used when a refrigerant that can easily ignite is used.

*1. Based on the test results of explosion-proof standard (IEC/EN) 60079-15.

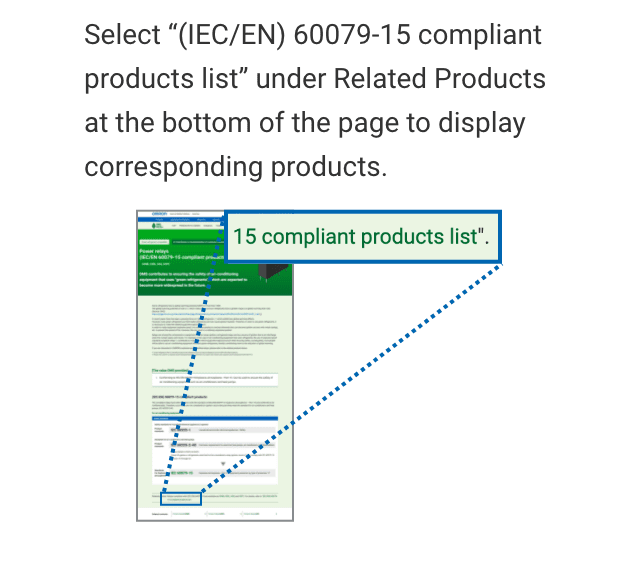

Checking products that meet your needs

Power relay

(explosion-proof certified product)

* Contents as of April 2024.

In the interest of product improvement, specifications are subject to change without notice