Please advise possible causes and countermeasures about electrical malfunctions of Photo IC type Photomicrosensors.

ID: FAQE40029E

update:

Answer

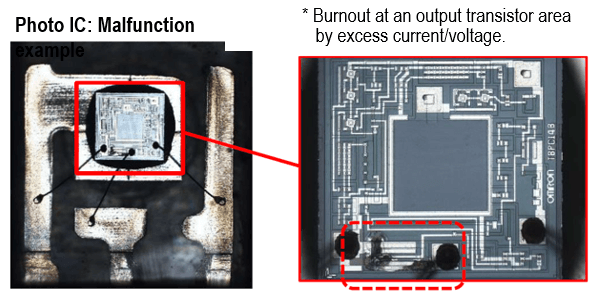

The majority of the electrical failures of Photomicrosensors are caused by electrical stresses such as overcurrent and overvoltage.

Explanation

The followings are possible causes of electrical failure of built-in type Photomicrosensors.

- The power supply voltage or current exceeds the specified rating.

- The output transistor is connected without a load.

- Reverse voltage is applied due to wrong wiring during assembly.

- Power line surge.

- There is the induction from high voltage line or power line which are wired parallel to the wiring of the sensor.

- A small inductive load such as a relay is used.

- Destroyed by static electricity during assembly.

Take the following measures for design, assembly and operation.

- Design the circuit so that it does not exceed the specified rating.

- As the internal element may burst or burn out, apply a load when wiring.

- If reverse voltage is applied to Photomicrosensors due to incorrect wiring during assembly, such as a wrong connector type, it may cause a failure even instantaneously. Turn on the power after sufficient confirmation.

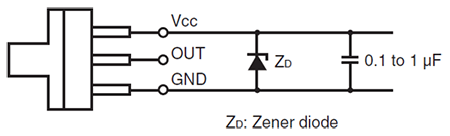

- If there is a surge in the power supply line, connect a Zener diode (30 to 35V) or capacitor (0.1 to 1μF) according to the operating environment. Confirm that the surge will go out before operation.

- If the wiring of Photomicrosensors is connected to the same wiring duct for high voltage line and/or power line, the induction may cause failure or malfunction. Use a separate wiring or a single wiring, and confirm that there is no induction.

- The load cannot be a relay.

- Photomicrosensors may be damaged by static electricity during assembly and mounting. Assemble and mount in an environment where static electricity is prevented.

Quick tips

No Tips

| Product category | Sensors Photomicro Sensors |

|---|---|

| Classification | Trouble shootings |

| Related keywords |

|