Are you familiar with OMRON's connector for easy-peasy connection? Connectors play the simple role of "connecting and disconnecting" electrical signals, but as devices become more multifunctional and sophisticated, manufacturing sites are filled with connector wiring. While there are many different connectors on the market from many different companies, OMRON offers connectors that are "easy-peasy to connect" by paying close attention to the "ease of use" of the customer. Why don't you try OMRON's connectors which incorporate what the maintenance and manufacturing workers who actually use the connectors say: "We wanted a connector like this!"?

Table of Contents

As the devices used in manufacturing sites become more sophisticated and multifunctional, the number of devices to be wired is also increasing. In proportion to this, maintenance work will naturally increase, and a connector that makes work easier, saves time, and reduces maintenance man-hours will become necessary. Please leave any "trouble" or "hassle" you are having now to OMRON's connectors.

3.5 mm-Pitch Push-In Terminal Block PCB Connectors

XW4M/XW4N

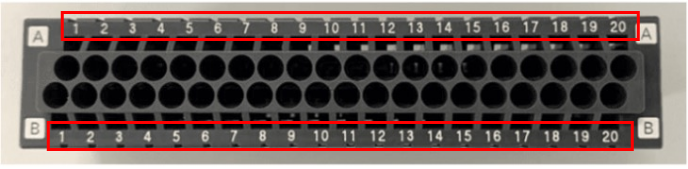

Numbered and easy to understand

One of the most common problems with connectors at work sites is that they are "just too hard." Even the force required to pull the connector out and insert it makes the work more difficult and time-consuming. XW4M/XW4N can be easily inserted and removed with one hand by anybody, reducing the workload and man-hours of maintenance.

![[Conventional connector]High insertion/removal force, requiring two hands => [OMRON's connector]Low insertion/removal force, easy for one-handed connection/disconnection. Contact reliability ensured by the ingenuity of the structure!](/sites/default/files/2023-01/easy_con_01_05_en.png)

Know-how

![[Structure of conventional connectors]The contact parts of conventional products will receive the contact force needed for engaging the wings one by one on each side, thus making it difficult to reduce the insertion and removal force.[OMRON's unique dual-spring structure]The unique dual-spring structure allows you to control the contact force, thus reducing the contact force of the connector and ensuring the contact force needed for engaging. * When engaged, contact reliability is ensured by the combined contact force of springs 1 and 2, and when inserted or removed, spring 2 is opened by lever operation to reduce the insertion/removal force. According to OMRON’s research in November 2020. Patent pending.](/sites/default/files/2023-01/easy_con_01_06_en.png)

There are many devices requiring connections on a site. While wiring is often done in confined spaces where you cannot use both hands, connectors that need both hands to make the connections require additional work such as moving devices or removing circuit boards, which can be time-consuming. XW4M/XW4N can be easily attached with one hand.

On a terminal block with countless pins, it is time-consuming and labor-intensive to count every time what pin to plug in, and above all, it is easy to make a mistake. That said, it is also troublesome and hard to read printed pin numbers on a board or other space. If you are making dozens or hundreds of terminal connections, this is probably one of the top things you want to eliminate.

Also, in the case of 2-piece connectors, the terminal block is often removed and the cables are wired for ease of work during maintenance. Even if the numbers are printed on the board, if the removed connector has no numbers printed on it, the only way for proper connection is to count the pin numbers. As a result, it is labor-intensive and likely to cause wiring errors.

XW4M/XW4N supports pin numbering as standard. Say goodbye to the hassle of counting pin numbers, printing them on other parts of the board, or making wiring mistakes.

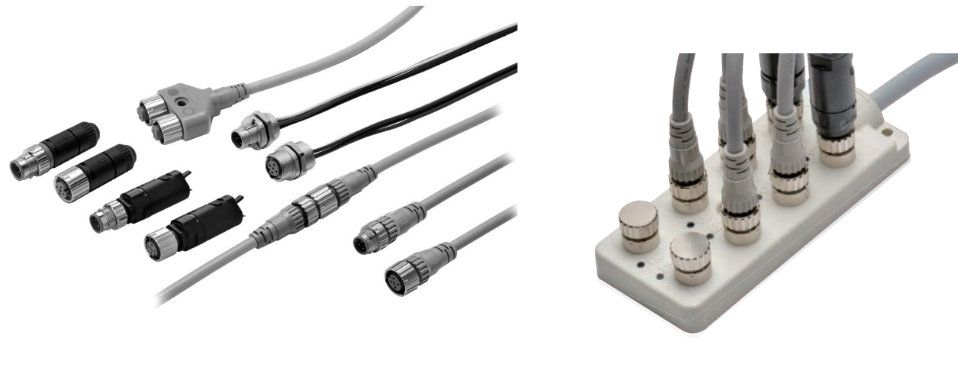

Round Water-resistant Connectors

XS5

For round connectors used in places with a lot of vibration, such as manufacturing sites, retightening of screws occurs regularly to prevent loosening. OMRON's smartclick XS5 does not loosen and does not need to be retightened like a screw once mated.

* Comparison between OMRON's M12 threaded connector and XS5. (Reference value)

XS5 can be quickly mated with a slight (1/8) turn, the shortest turn in the industry (smartclick method). There is no need to waste time turning until it stops as in the screw type.

Mating can be completed in about 4 seconds with the XS5, compared to about 12 seconds with conventional screw-type round connectors.

One of the most common problems in screw tightening is torque management. Although waterproof connectors are often required at manufacturing sites, the O-rings (rubber sealing) that prevent water from entering the connector get crushed through over-tightening, impairing the waterproof performance. With OMRON's XS5, however, it is easy to tell when work is complete by the sound and feeling of the "click" when it is turned. Torque management and dedicated torque tools are no longer necessary.

Know-how

The bayonet mechanism, which is widely used in telecommunications equipment, is incorporated into the connector structure. A latch inside the connector is hooked to lock the connector at 1/8 turn, eliminating concerns about loosening of the mating part.

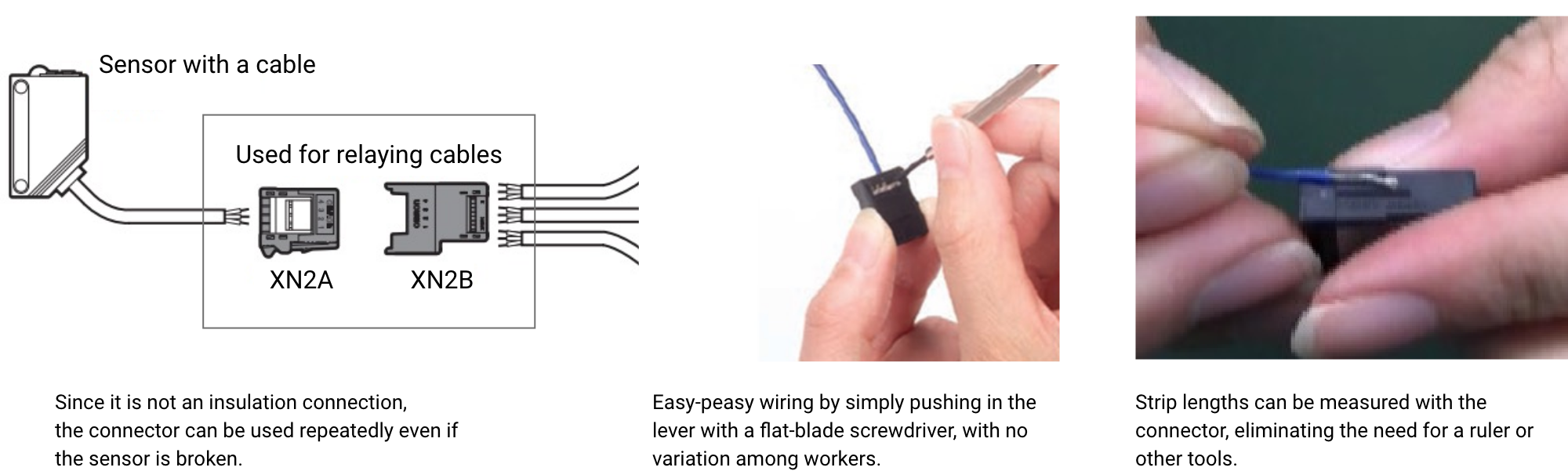

Easy-wire Connectors for Industrial Components

XN2A/XN2B

General board-to-cable connectors are not reusable once the wiring is made because the contacts are crimped or press-fit to the cable. Therefore, in most cases, the connector is discarded if there is a mistake in the cable wiring to the connector. OMRON's e-CON connector XN2A/XN2B, however, is a very eco-friendly product that allows repeated wiring. You only need a flat-blade screwdriver to push the lever in. There should be no variation among workers. Even if the sensor is broken, you simply need to reconnect to a new sensor, which contributes to work efficiency. The product is also equipped with a convenient strip measuring wire that can be used to measure the strip length and connect wires immediately on the spot, without the need for a ruler.

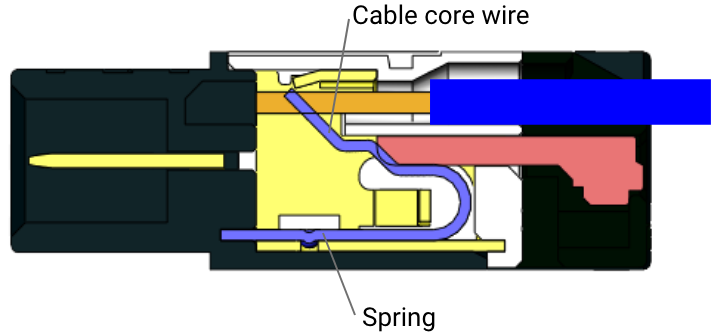

Know-how

A structure called a spring clamp method is used to tie the cable through contact pressure by holding down the cable with the force of a spring. Since the cable is only held down, the wiring can be redone repeatedly as many times as necessary.

There are many different sizes of cables mixed together on the sites. If the cable is between AWG28 to 20, a single connector can cover the range, and there is no need to change connectors depending on the size of the cable. Therefore enabling common use of connectors on the site and helps customers to reduce their inventory. It can be used for both single and stranded wires, and any type of conductor can be used.

Even at manufacturing sites where many products are produced every day, improving the connection efficiency of connectors is a great benefit. Connectors are used in both the equipment that is produced and the equipment that performs production. Even a small amount of effort can seem annoying when it comes to connecting hundreds or thousands of connectors, and you wish it could be as easy as possible.

By reflecting the "voice of the sites" in its products, OMRON's connectors help improve work efficiency, reduce cycle time and workers' workload, and increase productivity.

Rotary Backlock Type FPC/FFC Connectors

XF3M

Conventional connectors for FPC (flexible printed circuit)/FFC (flexible flat cable) required three actions: 1) release the slider, 2) insert the FPC/FFC, and 3) lock the slider. With OMRON's XF3M, the process of 1) releasing the slider is eliminated and only two actions are needed to perform the troublesome wiring. It contributes to improved production efficiency in the production process where FPC/FFC is inserted into connectors for hundreds of products per day.

![[Conventional connector]1.Unlock the slider, 2.Insert FPC/FFC, 3.Lock the slider => [OMRON's connector]No need for releasing the slider to save time and effort 1.Insert FPC/FFC, 2.Lock the slider](/sites/default/files/2023-01/easy_con_02_05_en.png)

Conventional FPC/FFC connectors have a narrow opening, making it difficult to insert cables. OMRON's XF3M has a structure with no top part of the opening for cables, making it easy to set even small, thin cables such as FPC/FFC cables. In addition, the locking structure is designed to provide a comfortable operation feeling so that you can immediately tell if the cable is properly locked, allowing you to work comfortably and easily.

![[Conventional connector]Narrow opening makes it difficult to insert FPC/FFC.[OMRON's connector]Large opening for easy-peasy connector insertion. Easy to know it's locked.](/sites/default/files/2023-01/easy_con_02_07_en.png)

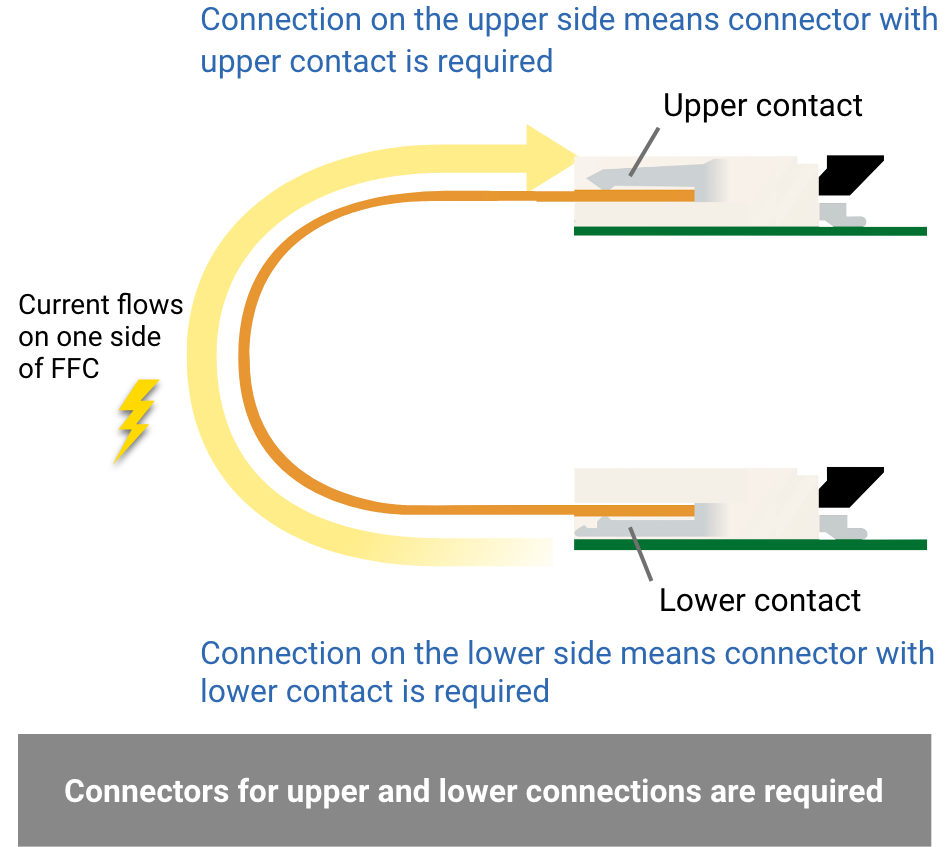

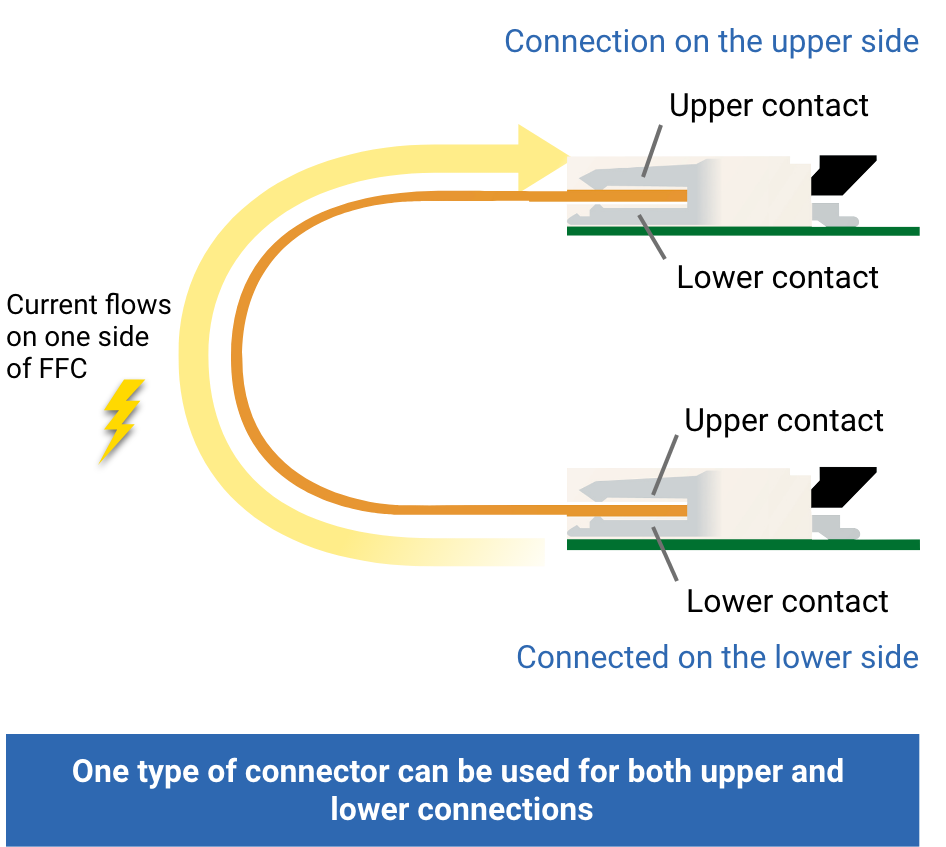

Only one type of connector is required for easy-peasy connection and management. When FFC is connected to the upper and lower boards as shown in the figure below, two types of connectors are required, one for the upper connection and the other for the lower connection. One of the problems customers face is that even a small effort can add up to a lot of time and effort for inventory management and maintenance. With OMRON's XF3M, a single connector can be used for both upper and lower connections, allowing parts to be shared. There is no need to waste time managing parts or checking the direction of contact points.

Connector with only one side contact

OMRON's connector with both upper and lower contacts

Flat Cable MIL Type Socket

XG4M-U

Discrete Wire Crimp Socket

XG5N-U

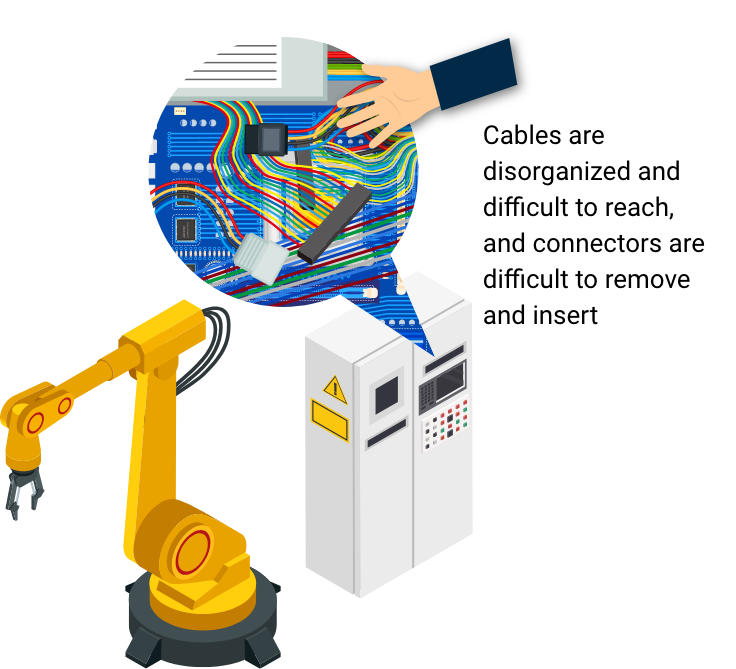

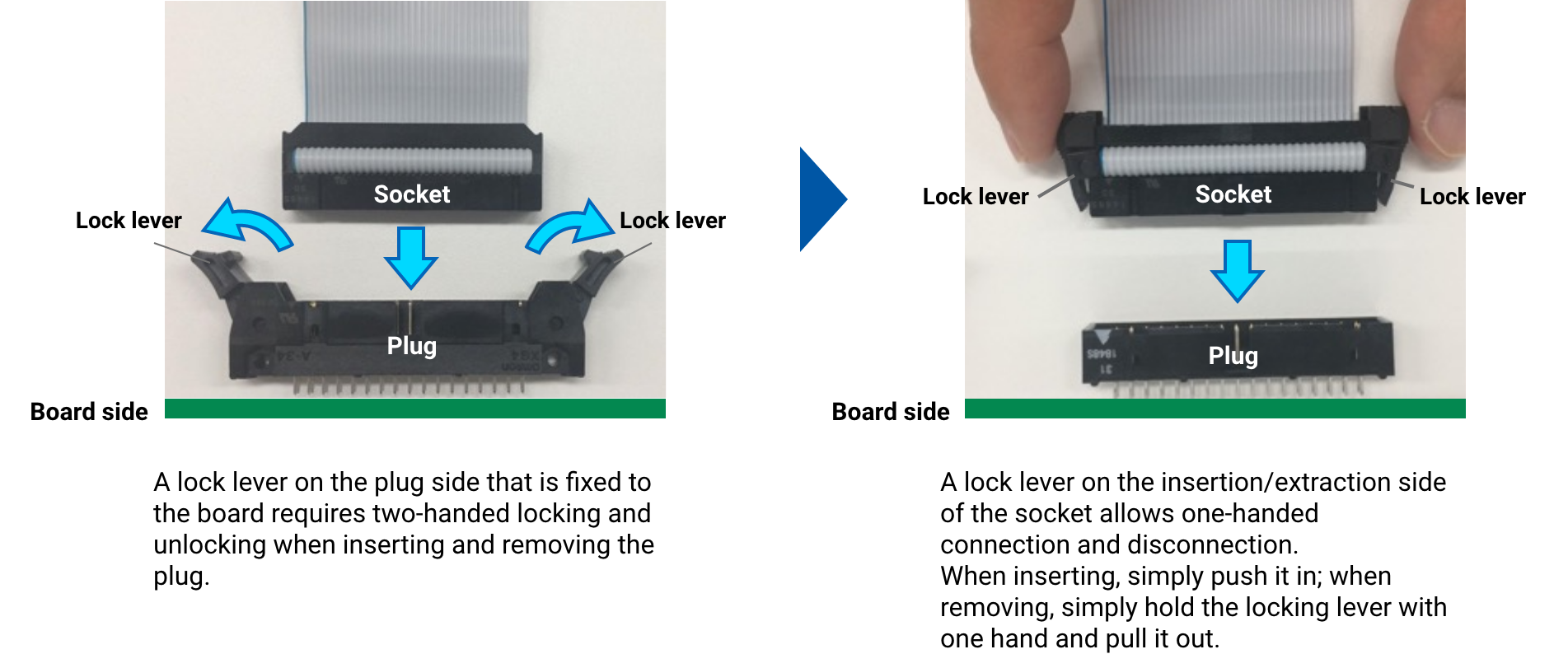

MIL connectors are invariably used in the wiring of industrial equipment that requires high reliability. Due to the issue of connector durability against shocks among others, a locking function is provided to securely fasten the connector to the board at manufacturing sites. A typical MIL-compliant connector has a locking lever on the plug on the board side. High-performance industrial equipment naturally has a large number of components and wiring integrated into it, and inserting and removing plugs and sockets with both hands is more difficult than one might imagine. Depending on the layout of the board, the connectors may be located at the back of the equipment, making it difficult to put fingers in when making connections.

OMRON's MIL connector lineup, in addition to the general-purpose type with a lock lever on the plug side, includes a type with a lock lever on the socket side where the cable is attached. By attaching a lever on the side to be inserted or removed, it can be easily inserted or removed with one hand, even in tight spaces.

Conventional MIL connectors have thin, sharp locking parts, and locking and unlocking the stiff lock lever over and over again is hard on the fingers. In a high-volume production site, hand pain is directly related to decreased work efficiency. OMRON's XG4/XG5 series locks are approximately twice as wide as conventional MIL connectors, allowing easy connection and disconnection of connectors without finger pain.

: 8mm; (Slim lock type): 3.5mm](/sites/default/files/2023-01/easy_con_02_18_2_en.png)

DIN Connector with Stop Pin Series

XC5□-□□□□-A

For product details, contact OMRON's sales department.

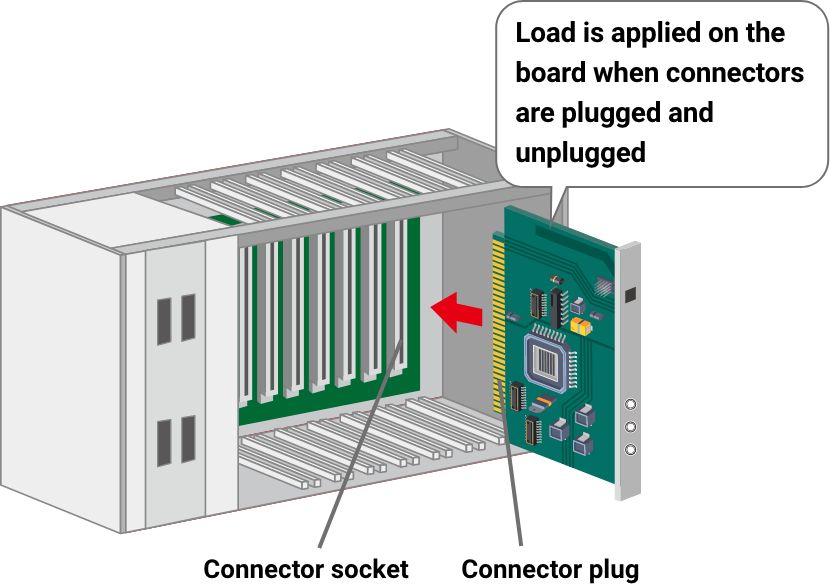

As connectors are only components for electrical connection, they are not good at mechanically supporting the board. Board-to-board connectors require board mounting strength because when the connector is pulled out, the board is pulled as well and there is a load on the board itself. To increase strength, connectors are screwed on and then soldered over, which was time-consuming and labor-intensive.

OMRON's connectors with set pins allow one-touch fixation by simply inserting the left and right set pins into the board. Since the board mounting strength can be secured without screwing, mounting can be done simply by soldering the stop pins, accelerating the work.

Testing Socket

XP2U-001

USB Type-C connectors are often seen on smartphone and laptop chargers. Once inserted, however, they have a lock that prevents them from easily coming off unless a little force is applied. We often operate our smartphones while charging them, but OMRON offers Type-C sockets that do not have locks and are "easy to plug and unplug".

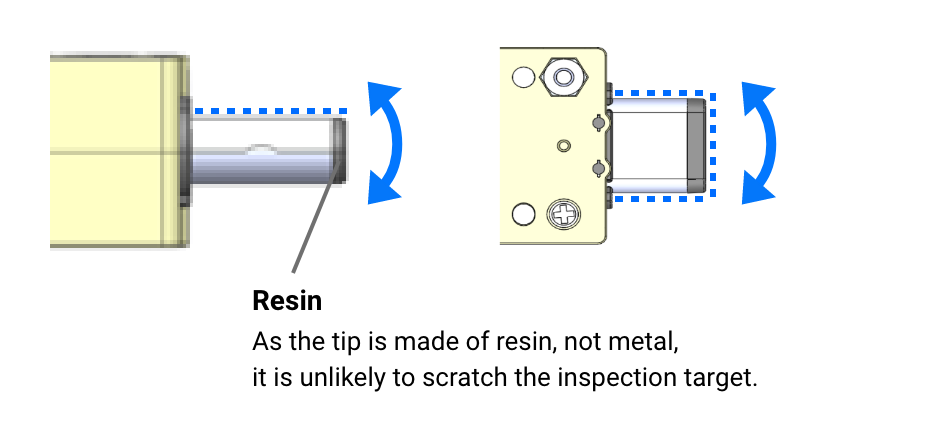

For example, in the manufacturing process of smartphones that charge via USB Type-C, a continuity test is always performed. In the continuity testing of smartphones, which requires plugging and unplugging tens or hundreds of thousands of times a day, OMRON's XP2U-001 has no locking mechanism and can be smoothly plugged and unplugged with light force, eliminating the need to hold the product firmly and reducing the risk of damage to the product.

Anyone who buys a "brand-new product" is sensitive to even the tiniest flaw. This is especially true for very expensive precision equipment such as smartphones. In order to avoid damage to products caused by insertion errors in the final inspection process, many manufacturing sites may perform continuity testing (i.e., connector plugging and unplugging) by hand instead of using automatic machines.

The terminal of the XP2U-001 has a floating structure that allows for vertical and horizontal movement. The movable tip prevents insertion errors due to misalignment of insertion/removal in the automated inspection process and realizes "easy-peasy insertion/removal in automated machines." It also prevents machine stoppages due to insertion errors, thus contributing to increased work efficiency in the inspection process. From now on, why don't you try an easy-peasy inspection with an automated machine instead of manual work?

Know-how

The terminal of the XP2U-001 has a floating structure that allows for vertical and horizontal movement. The flexible tip allows insertion without resistance even when the insertion angle is not perfectly horizontal. It can prevent damage to products due to connector insertion errors in automated inspection processes.

In a production site where hundreds or thousands of inspections are performed daily, maintenance work is an inseparable part of the process. One of the challenges that arise during continuity testing of precision equipment is the "rapid failure of connector cables." A typical connector cable will last approximately thousands of cycles for short-lived cables and tens of thousands of cycles for long-lived ones. As a result, in many cases two tasks occur several times a day: Checking the condition of connectors and replacing them. OMRON's XP2U-001, which boasts mechanical durability of more than 200,000 cycles, can significantly reduce the frequency of connector replacement.

| General test socket | General USB cable | XP2U-001 | |

| Mechanical durability | 3,000 to 10,000 times | 3,000 times | More than 200,000 times |

* According to OMRON’s research in September 2022

What designers are looking for in a connector is probably still a "secure connection". With the demand for high functionality and miniaturization, there will be cases where a design with no wiring space to spare is required. OMRON offers connectors with a structure that makes "secure connection" easy. You can design without worrying about "it might come off".

Rotary Backlock Type

FPC/FFC Connector

XF3M

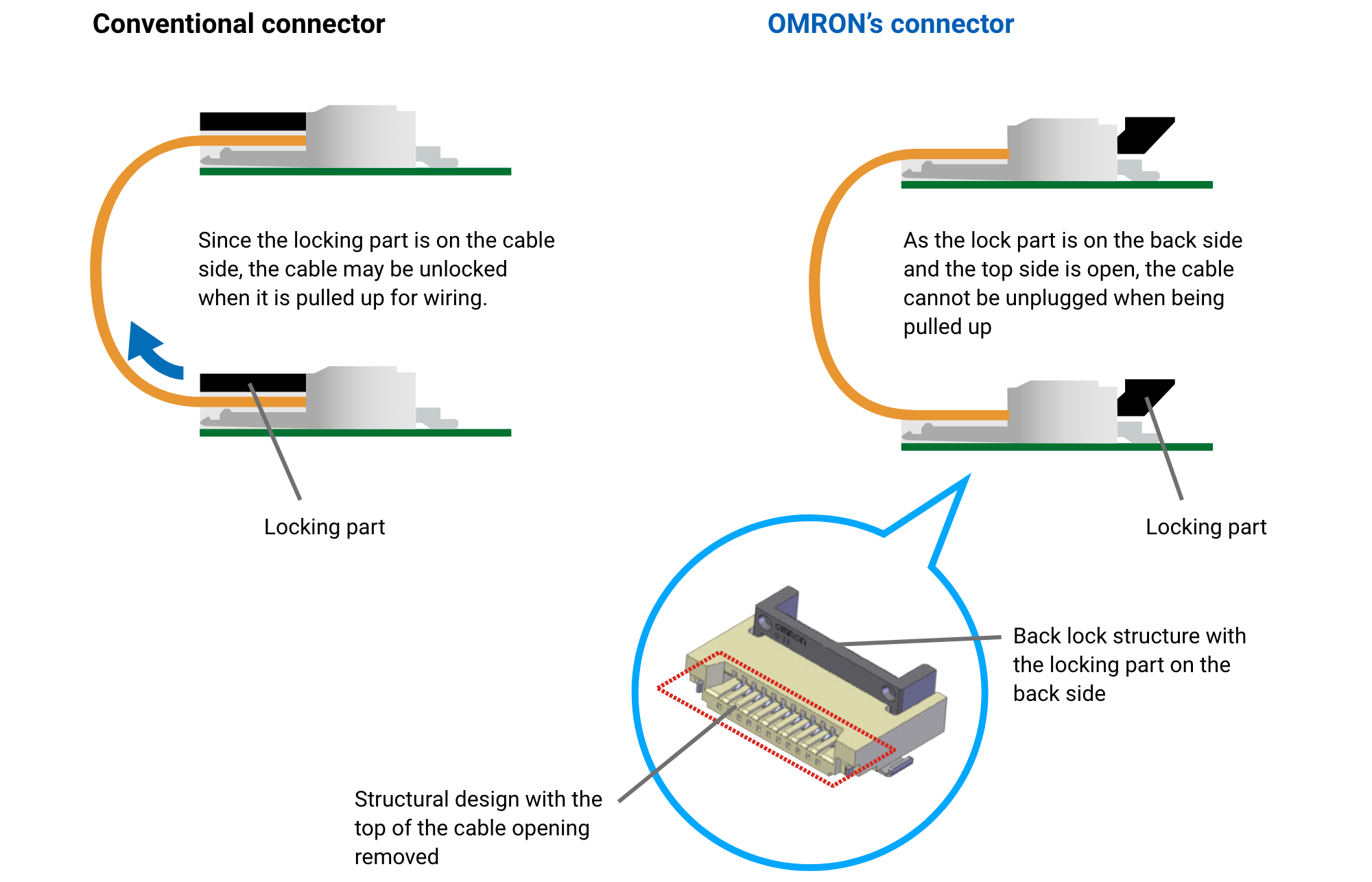

For connectors mounted on small general-purpose equipment, there are cases where there is not ample space for cable routing at the time of design. When the locking part is on the cable connection side, and if there is not enough space for wiring, the cable could be unlocked by being pulled upward when the connectors are plugged at upper and lower sides. For a "secure connection", you need to take into account at the time of design to thoroughly eliminate such a concern. OMRON's XF3M, which places the locking part on the back side and has no upper side of the cable insertion area, ensures a secure connection without cable disconnection.

![Easy-peasy connection that completely eliminates "waste" of work. Easy to use, that's what OMRON connectors are for.[Easy-peasy for maintenance][Easy-peasy for manufacturing site][Easy-peasy for design]](/sites/default/files/2023-01/easy_con_head_en.png)