vol.264 January 2023

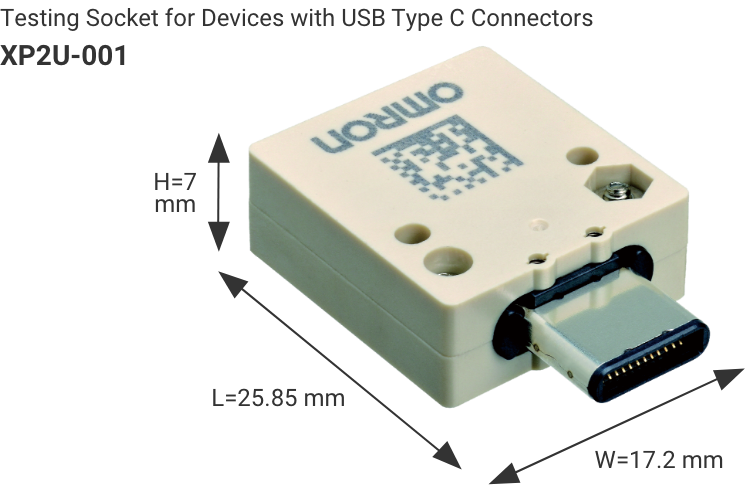

Testing socket for devices with USB type C connectors capable of 20 times more insertions and removals

Superior durability and ultra-low insertion/removal force contribute to reduced burden on inspection personnel and automation of insertion/removal, as well as reduction of damage to the product to be inspected.

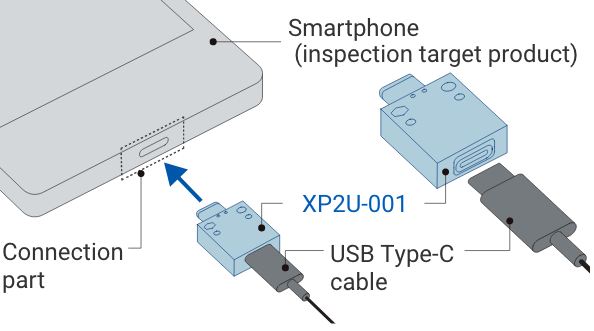

Application example

Product inspection using USB Type-C connectors (e.g., smartphones)

Performance comparison with general test sockets and USB Type-C cables*1

| Value for customers | XP2U-001 | General test socket | General USB Type-C cable |

|---|---|---|---|

| Damage to the product to be inspected |

Avoidable |

Unlikely to |

Likely to |

| Number of insertions and removals (high durability) |

200,000 times |

3,000 to |

3,000 times |

| Ultra-low insertion /removal force (force required for insertion/removal) |

Very light |

Light |

Resistant |

*1. According to OMRON's research in September 2022.

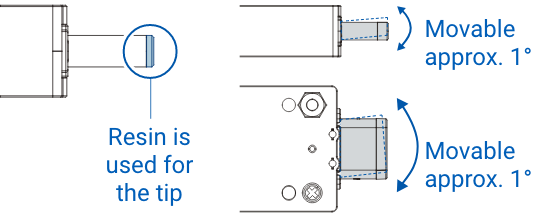

Resinized tip reduces damage to the product to be inspected

Resin tip can prevent damage of products to be inspected. In addition, the floating structure allows the terminal to move vertically and horizontally, preventing damage to the product caused by mis-insertion of the connector during the automated inspection process.

High durability to withstand 200,000 insertion tests

Electroformed contact pins made of an alloy with high degree of hardness and excellent springiness maintain conduction with stable contact resistance even after 200,000 insertion tests.

Sufficient gold plating thickness remains on the contact area of the contact pin even after 200,000 times of pin insertion test.

Ultra-low insertion/removal force greatly reduces workload

An unlocking structure has been adopted, eliminating the locking mechanism used in general USB Type-C cables.

It can be inserted and removed with approximately 1/5 to 1/7 of the force of a general USB Type-C cable.

The ultra-low insertion/removal force greatly reduces the manual workload in the inspection process and contributes to automation.

XP2U-001 OMRON's proprietary*2 EFC process technology:

Electroforming process technology used for contact pins

EFC process technology, which utilizes microfabrication and electroforming methods, gives form to complex and unique shapes

OMRON's proprietary EFC process technology enables the machining of complex shapes on the order of microns with high precision.

The ability to produce complex and unique shapes makes it possible to mass produce contact pins with excellent durability, springiness, and conductivity.

*2. Two patents (US8337261;US2013/0045617) have been granted for the electroforming technology to form the contact structure and its manufacturing process.

A highly springy pin design absorbs vibrations caused by shaking and impact, making contact failure less likely.

* Contents as of December 2022.

In the interest of product improvement, specifications are subject to change without notice