vol.251 December 2021

Surface mounting of mechanical components that do not proceed as expected

Surface mounting is indispensable for downsizing and densifying PCBs and reducing man-hours. However, there are few options for mechanical components, and issues such as mounting strength and excessive MOQ*1 have hindered progress as much as expected.

OMRON is responding to these challenges by strengthening its product lineup, THR support, and small-lot supply.

Three initiatives help promote surface mounting of mechanical components

01 Strengthening the assortment of SMD types in 4 categories

Large selection of SMD types in all categories of connectors, sensors, relays, and switches.

We will continue to strengthen our lineup of SMD types that demonstrate the same specifications as existing dip components.

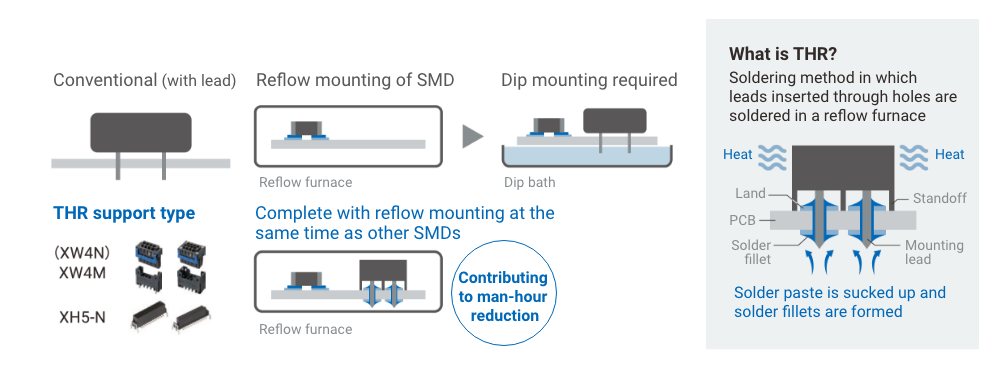

02 THR-compatible connectors that ensure mounting strength are released

THR (Through Hole Reflow) connectors XW4M (XW4N) and XH5-N (some models) can be reflow-mounted with the same strength as dip components soldered in conventional dip mounting.

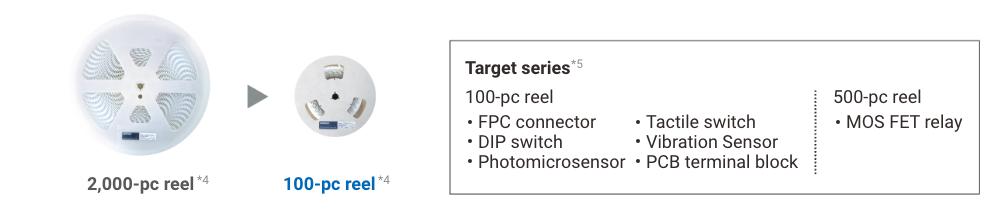

03 Approx. 70 series*3 in 4 categories of small-lot 100-piece reels are available

While several thousand pieces are usually required for MOQ*1, OMRON offers a variety of small-lot products ranging from 100 to 500 pieces.

Efficient surface mounting with less waste is possible.

*1. Minimum Order Quantity: The number of items in minimum order

*2. According to OMRON's research in November 2021.

*3. According to OMRON's research in November 2021. Four categories of connectors, sensors, relays, and switches.

*4. The number of items in a reel is an example of switch B3SE. Please contact us for more details.

*5. Please contact us for supported models.

* Contents as of November 2021.

In the interest of product improvement, specifications are subject to change without notice