If the side of a relay is coated with silicon that contains siloxane (low molecular-weight siloxane reducer) in the coating agent, will contact failure occur? What about urethane coating?

ID: FAQE10061E

update:

Answer

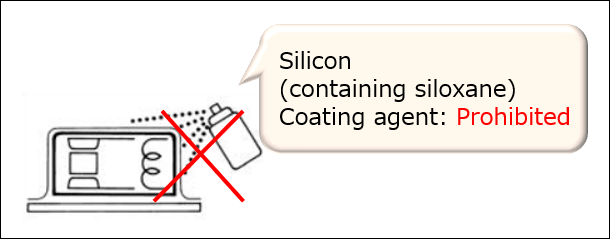

Use a siloxane-free coating agent. Even low molecular-weight siloxane-reduced agents may cause contact failure of relay contacts. Urethane-based coating agents can be used.

Explanation

If coating agent, packing resin, etc., enters the relay, contact failure and/or malfunction may occur. Please prevent them from entering the relay. For coating and packing, use a plastic-sealed relay. Use silicon-free coating and packing resin.

- Siloxane

Siloxane is highly permeable and penetrates into the interior of plastic-sealed relays.

Even siloxane-reduced agent contains siloxane, which only prolongs the time it takes to enter the relay.

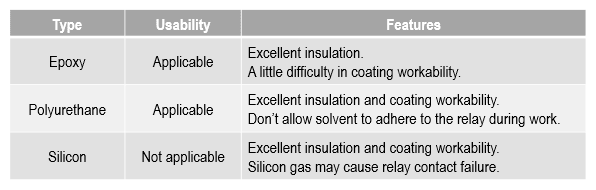

After entry, a silicon oxide film is formed on the contact, causing contact failure. Therefore, silicon-based coating cannot be used, even on only the side of the relay. - Urethane / epoxy

Urethane and epoxy coating agents can be used but they may contain a small amount of siloxane. Please check the ingredients before use.

- Other coatings

Please use siloxane-free (silicon-free) resin molding, potting, and packing on the PCB surface.

For more information, see Safty Precautions for All Relays: 4 Relay Mounting Operations

For more information, see Safty Precautions for All Relays: 6-10 Automatic Mounting of Relays for PCBs.

Quick tips

When a coating (including mold, potting, and packing) is applied, make sure that the insulation property does not deteriorate and that the material (resin or metal) used for the relay is not affected before selecting.

| Product category | Relays Signal Relays Power Relays |

|---|---|

| Classification | Mounting, Storage |

| Related keywords |

|