vol.257 June 2022

Miniaturization does not mean just making components smaller.

For designers, "miniaturization" is an eternal challenge.The standard approach to miniaturization is to make components smaller, but in fact, it is also possible to reduce the size of PCB and devices by reviewing the way components are used.

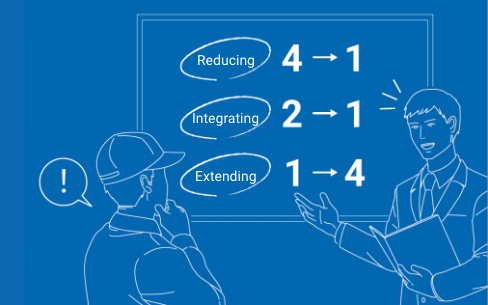

OMRON responds to the eternal challenge of "miniaturization" by reducing, integrating, and extending the components themselves, in addition to making them smaller and thinner.

Reviewing the use of components opens up new possibilities for miniaturization.

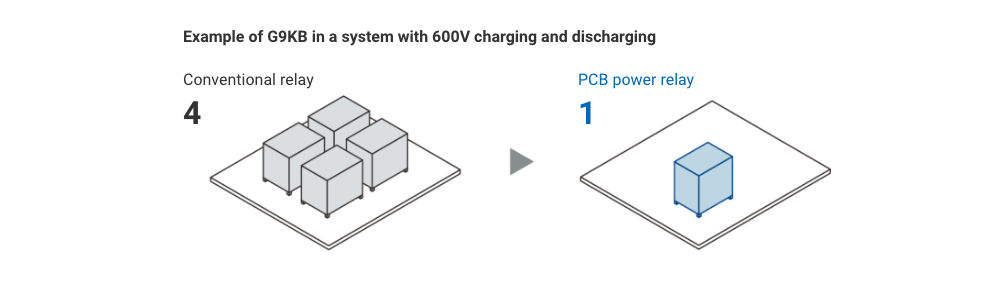

Reducing 4→1

Reducing the number of mounted components by supporting high-capacity and bi-direction→Reducing "PCB" size

The use of high-capacity, bi-directional switching relays can reduce the number of components required, allowing the reduction of the number of components to make PCB smaller. This is effective for miniaturization of batteries.

[ NEW ] |  |

|---|---|

PCB Power Relay G5PZ-X (for DC loads) |  |

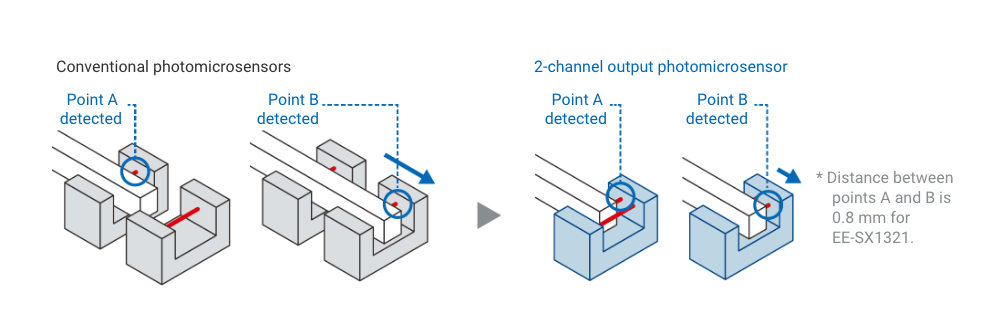

Integrating 2→1

Integrating two sensing components into one→Reducing "PCB" and "Device" size

Two conventional sensors are required for detection of two points, but a sensor with 2-channel output can be used with only one sensor, reducing the installation space.

Photomicrosensor (Transmissive) EE-SX1321 |  |

|---|

Extending 1→4

Making components smaller while extending OT→Smaller "device" for easier mechanical design

Extending the OT (Over Travel: movement after operation) from 1.2 to 4.45 mm reduces the size of the component itself as well as making the mechanical design easier and reducing the device size.

Sealed Ultra Subminiature Basic Switch D2GW |  |

|---|

* Contents as of May 2022.

In the interest of product improvement, specifications are subject to change without notice