Can I coat the PCB after mounting a relay?

ID: FAQE10060E

update:

Answer

For coating, use a plastic-sealed relay. Consider the coating agent introduced in the Explanation. However, do not use silicon-based coatings.

Explanation

Coating

- Do not coat the encased relay or flux-resistant relay, as it may cause contact failure when the coating agent penetrates into the relay. Alternatively, mount the relay after coating.

- Depending on the type of coating agent, the case of the relay may be damaged, or the sealing agent may be dissolved chemically, which may damage the sealing.

- Do not resin-harden the entire relay. This may cause a change in relay characteristics. The temperature of the coating agent must not exceed the maximum ambient operating temperature.

Types of coating agents

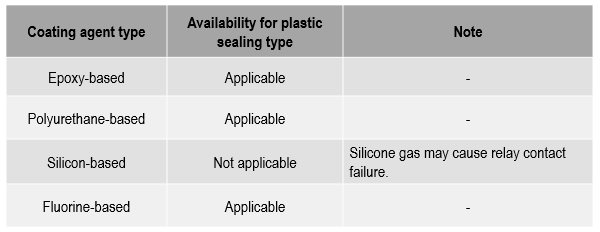

- Please use silicon-free coating and packing resin.

- The table below shows the main coating agents and their availability on PCB relay.

For more information, see Safty Precautions for All Relays: 6-10 Automatic Mounting of Relays for PCBs.

Quick tips

If the coating agent enters the gap between the relay and PCB and is not cured, it may cause the insulation between the relay terminals to deteriorate. Check the dry condition and the insulation resistance of the relay (between contacts and between coil contacts).

| Product category | Relays Signal Relays Power Relays |

|---|---|

| Classification | Mounting, Storage |

| Related keywords |

|