What are countermeasures to silicone for a basic switch?

ID: FAQE20043E

update:

Answer

As stated in the catalog, we do not recommend using the products in an atmosphere with silicone gas. Unless you remove the silicone gas from the environment, it is difficult to eliminate the problem for switches with contacts.

Explanation

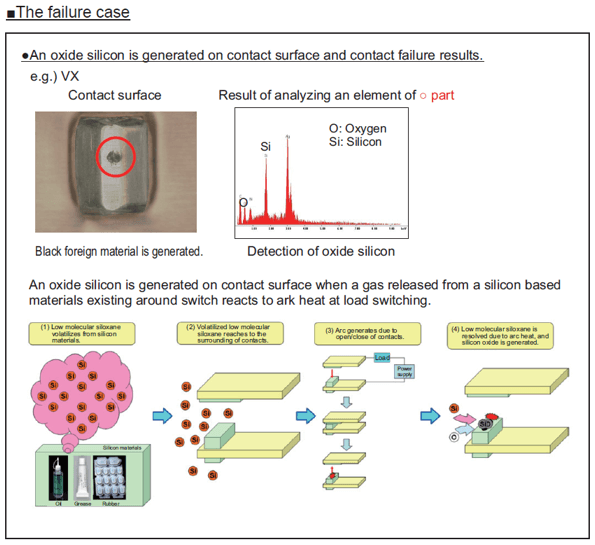

When electrical switching is performed in an atmosphere with silicone gas, silicon dioxide may accumluate on the contacts and cause contact failure. An oxide silicon is generated on contact surface when a gas released from a silicone based materials existing around switch reacts to ark heat at load switching. The followings are examples of a source of generating a silicone gas.

- Silicone based coating agents

- Slicone based adhesive

- Silicone rubber

- Silicone oil/grease

- Silicone based mold lubricant

- Silicone filler

- Silicone wire, etc.

If there is a source of generating a silicone gas, be sure to eliminate the source around the switch or change to the other materials.

Silicone based mold lubricant in die may be used in molding, so make sure not to use it. In addition, if using under environment where a source of generating a silicone gas exists, be sure to implement the periodical check or replacement.

For more information, please see The Solution[Micro switch].

Quick tips

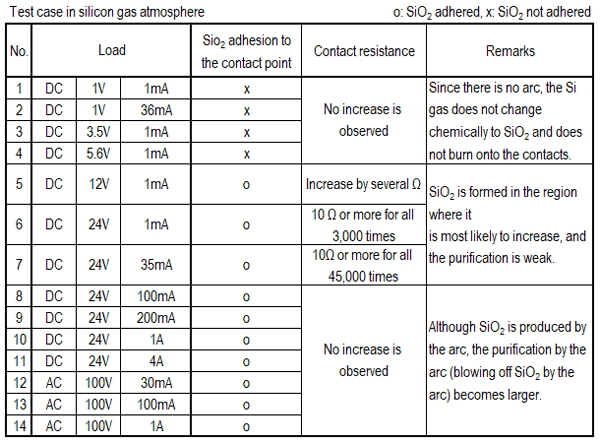

Please refer to the following table for information on electrical switching in environments with silicone gas. There is also a suppression effect depending on switching voltage and current. The evaluatation with your actual equipment must be performed.

We have D2QW and D2AW basic switches with sliding contacts. They are only for a microload type, but silicon dioxide can be removed to some extent by the sliding contacts. The evaluatation with your actual equipment must be performed.

| Product category | Switches Basic Switches |

|---|---|

| Classification | Trouble shootings |

| Related keywords |

|